Na2xby N2xby Aluminium Conductor IEC60502-1 XLPE Dsta PVC 0.6/1kv Cable

Product Description

This cable is highly resistant against mechanical stresses due to the galvanised steel tape armoured construction. Suitable for local distribution systems.

The NA2XBY and NA2XH cables are designed for local distribution systems and for delivering power and auxiliary control in the Building and Construction industry. The NA2XBY is highly resistant to mechanical stresses as a result of the double layer of galvanized steel tape armour applied to the cable.

Available with Cross-Linked Polyethylene (XLPE) insulation and a Polyvinyl Chloride (PVC) oversheath, these cables have a voltage rating of 600/1000V and a maximum operating temperature of +90oC. The cables are not suitable for use in water.

The Thermoplastic halogen-free compound sheath cable is available with aluminium conductors as follows:

RE – Class 1 solid aluminium-circular or circular compacted

RM – Class 2 stranded

SE – Class 1 solid sector-shaped or stranded

SM – Class 2 sector-shaped to BS EN 60228 (previously BS 6360)

The standard PVC sheathed NA2XBY cable is available with a Class 2 stranded conductor.

CABLE STANDARDS of NA2XBY N2XBY Aluminium Conductor cable:

TS IEC 60502-1, IEC 60502-1, VDE 0276, IS 1516.1, BS EN/IEC 60332-1.

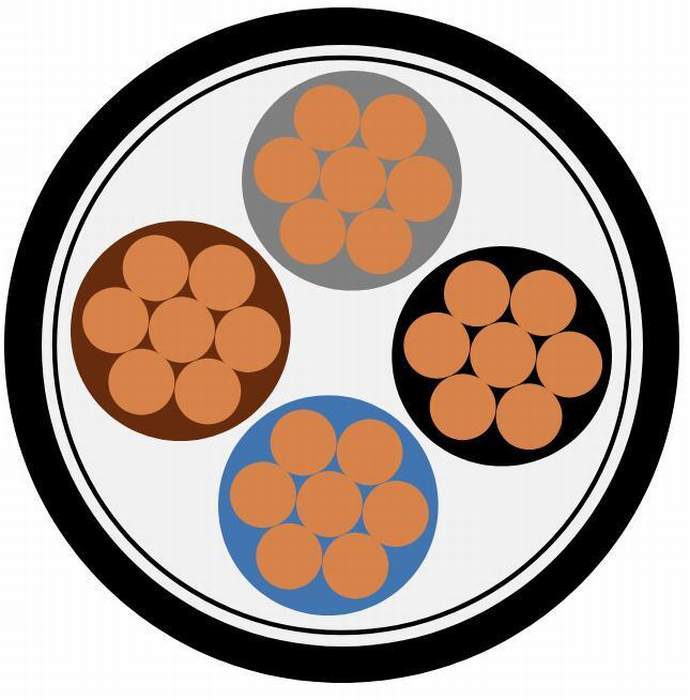

CONSTRUCTION of NA2XBY N2XBY Aluminium Conductor cable :

Conductor : Class 2 stranded aluminium conductor according to BS EN 60228 (previously BS 6360).

Insulation : XLPE (Cross-Linked Polyethylene) .

Filler : PVC (Polyvinyl Chloride) .

Armour :Double galvanized steel tape .

Sheath : PVC (Polyvinyl Chloride).

CHARACTERISTICS of NA2XBY N2XBY Aluminium Conductor cable:

Voltage Rating (Uo/U) 600/1000V

Test Voltage 3.5kV

Maximum Operating Temperature +90°C

Maximum Short Circuit Temperature +250°C

Minimum Bending Radius 15 x overall diameter

Sheath Colour Black.

Technical Parameter of N2XBY Aluminium Conductor cable:

|

Conductor |

Inductance |

Current – Carrying Capacity at 30° C * |

Short circuit current at 1 sec |

|||

|

Nom. Cross Section Area |

DC Resistance at 20°C |

AC Resistance at 90°C |

||||

|

in air |

in ground |

|||||

|

(mm²) |

Max. (/km) |

Max. (/km) |

(mH/km) |

Max. (A) |

Max. (A) |

Max. (kA) |

|

1.5 |

12.1 |

15.429 |

0.315 |

27 |

32 |

0.21 |

|

2.5 |

7.41 |

9.449 |

0.293 |

36 |

42 |

0.36 |

|

4 |

4.61 |

5.878 |

0.275 |

48 |

55 |

0.57 |

|

6 |

3.08 |

3.927 |

0.263 |

60 |

68 |

0.86 |

|

10 |

1.83 |

2.334 |

0.248 |

83 |

91 |

1.43 |

|

16 |

1.15 |

1.467 |

0.238 |

110 |

118 |

2.29 |

|

25 |

0.727 |

0.927 |

0.240 |

148 |

152 |

3.58 |

|

35 |

0.524 |

0.669 |

0.233 |

183 |

183 |

5.01 |

|

50 |

0.387 |

0.494 |

0.232 |

214 |

210 |

7.15 |

|

70 |

0.268 |

0.343 |

0.229 |

269 |

256 |

10.01 |

|

95 |

0.193 |

0.247 |

0.224 |

334 |

309 |

13.59 |

|

120 |

0.153 |

0.197 |

0.223 |

386 |

350 |

17.16 |

|

150 |

0.124 |

0.160 |

0.224 |

449 |

395 |

21.45 |

|

185 |

0.0991 |

0.129 |

0.225 |

512 |

444 |

26.46 |

|

240 |

0.0754 |

0.099 |

0.223 |

604 |

513 |

34.32 |

|

300 |

0.0601 |

0.081 |

0.221 |

692 |

577 |

42.90 |

Specification Date Sheet of NA2XBY Aluminium Conductor cable:

|

Conductor |

Overall Diameter |

Cable Weight |

Inductance |

Current – Carrying Capacity at 30° C * |

Short circuit current at 1 sec |

|||

|

Nom. Cross Section Area |

DC Resistance at 20°C |

AC Resistance at 90°C |

approx. |

approx. |

in air |

in ground |

||

|

(mm²) |

Max. (/km) |

Max. (/km) |

mm |

kg/km |

(mH/km) |

Max. (A) |

Max. (A) |

Max. (kA) |

|

10 |

3.08 |

3.949 |

19.7 |

519 |

0.248 |

64 |

70 |

0.94 |

|

16 |

1.91 |

2.449 |

23.0 |

685 |

0.236 |

86 |

91 |

1.50 |

|

25 |

1.20 |

1.539 |

25.5 |

880 |

0.242 |

114 |

118 |

2.35 |

|

35 |

0.868 |

1.113 |

28.5 |

1,097 |

0.234 |

141 |

142 |

3.29 |

|

50 |

0.641 |

0.822 |

32.5 |

1,196 |

0.232 |

166 |

163 |

4.70 |

|

70 |

0.443 |

0.568 |

37.0 |

1,586 |

0.229 |

209 |

199 |

6.58 |

|

95 |

0.320 |

0.411 |

42.5 |

2,399 |

0.224 |

259 |

239 |

8.93 |

|

120 |

0.253 |

0.325 |

47.5 |

2,919 |

0.223 |

300 |

272 |

11.28 |

|

150 |

0.206 |

0.265 |

53.5 |

3,482 |

0.225 |

349 |

307 |

14.10 |

|

185 |

0.164 |

0.211 |

57.5 |

4,125 |

0.225 |

399 |

346 |

17.39 |

|

240 |

0.125 |

0.162 |

64.0 |

5,122 |

0.223 |

473 |

401 |

22.56 |

|

300 |

0.100 |

0.130 |

69.5 |

6,088 |

0.222 |

543 |

453 |

28.20 |

- Next: AAAC All Aluminum Alloy Conductor with IEC DIN ASTM Standard

- Previous: House Wiring PVC Insulated Flat Twin and Earth Wire Cables

Contact us

Similar Or Related

-

IEC 60502-1 IEC 60228 XLPE Insulated Power Cable High Electric Strength

-

0.6/1kv Copper Conductor XLPE Insulated Steel Tape Armoured PVC Sheathed Contral Cable N2xby

-

0.6/1kv Nh-Yjv22 N2xby 4 Cores Cu/Mica/XLPE/Dsta/PVC Power Cable

-

0.6/1kv N2xby Electrical Cable Low Voltage LV N2xby Electric Cable

-

Na2xby N2xby Aluminium Conductor IEC60502-1 XLPE Dsta PVC 0.6/1kv Cable