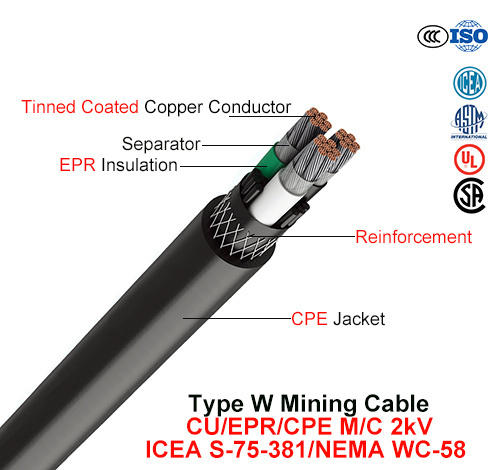

Type W, Mining Cable, Cu/Epr/CPE, M/C, 2kv (ICEA S-75-381/NEMA WC-58)

Product Description

Features

Meets all requirements of ICEA S-75-381. Reformulated compounds suitable for CV curing, developed to meet the high level of physical properties required in service. Flame, abrasion, sunlight, oils, solvents, acids and ozone resistant. -40 °C Rating CPE Jacket.

Application

Type W is a portable or fixed power cable used in mining and industrial applications where high reliability is required. For use in wet or dry locations, installed in conduits, ducts or trays and sunlight exposed.

Standards

ICEA S-75-381/NEMA WC-58 Portable and Power Feeder Cables for Use in Mines and Similar Applications.

CFR Title 30 Federal Regulations.

MSHA 7K-228054

Specifications

Maximum operating voltage: ? 2 kV

Maximum conductor operation temperature: ? 90 °C wet or dry locations under normal operating conditions.

Engineering Information

1. Conductor: Soft or annealed tinned coated copper conductor, rope lay flexible stranding per ASTM B172.

2. Separator: A separator may be applied over the conductor.

3. Insulation: High quality, heat, moisture, ozone and, thermosetting ethylene propylene rubber (EPR) meeting ICEA S-75-381.

Phase ID: Color coded insulation

2/C – BL, WH

3/C – BL, WH, GR

4/C – BL, WH, RE, GR

4. Assembly: Phase conductors cabled together with nonhygroscopic fillers as required and a binder tape.

5. Jacket: Black heavy duty chlorinated polyethylene (CPE) compound, applied in one layer over a fibrous reinforcement layer.

| Conductor Size | Number of Strands | Size of Each Strand | Nominal Insulation Thickness | Maximum Overall Diameter | Approximate Total Weight |

| AWG or kcmil | AWG | mil | in | lb/kft | |

| 2 Conductors | |||||

| 8 | 133 | 29 | 60 | 0.84 | 396 |

| 6 | 133 | 27 | 60 | 0.94 | 531 |

| 4 | 259 | 28 | 60 | 1.11 | 766 |

| 2 | 259 | 26 | 60 | 1.3 | 1095 |

| 1 | 259 | 25 | 80 | 1.47 | 1398 |

| 1/0 | 259 | 24 | 80 | 1.56 | 1620 |

| 2/0 | 329 | 24 | 80 | 1.69 | 1969 |

| 3/0 | 413 | 24 | 80 | 1.82 | 2339 |

| 4/0 | 532 | 24 | 80 | 1.97 | 2547 |

| 250 | 608 | 24 | 95 | 2.16 | 2964 |

| 300 | 741 | 24 | 95 | 2.28 | 3420 |

| 350 | 855 | 24 | 95 | 2.42 | 3918 |

| 500 | 1221 | 24 | 95 | 2.76 | 5389 |

| 3 Conductors | |||||

| 8 | 133 | 29 | 60 | 0.94 | 497 |

| 6 | 133 | 27 | 60 | 1.04 | 652 |

| 4 | 259 | 28 | 60 | 1.2 | 921 |

| 2 | 259 | 26 | 60 | 1.37 | 1297 |

| 1 | 259 | 25 | 80 | 1.54 | 1633 |

| 1/0 | 259 | 24 | 80 | 1.69 | 1996 |

| 2/0 | 329 | 24 | 80 | 1.79 | 2379 |

| 3/0 | 413 | 24 | 80 | 1.94 | 2869 |

| 4/0 | 532 | 24 | 80 | 2.09 | 3212 |

| 250 | 608 | 24 | 95 | 2.45 | 4086 |

| 300 | 741 | 24 | 95 | 2.62 | 4825 |

| 350 | 855 | 24 | 95 | 2.74 | 5423 |

| 500 | 1221 | 24 | 95 | 3.09 | 7405 |

| 4 Conductors | |||||

| 8 | 133 | 29 | 60 | 1.02 | 585 |

| 6 | 133 | 27 | 60 | 1.13 | 780 |

| 4 | 259 | 28 | 60 | 1.3 | 1102 |

| 2 | 259 | 26 | 60 | 1.51 | 1599 |

| 1 | 259 | 25 | 80 | 1.71 | 2016 |

| 1/0 | 259 | 24 | 80 | 1.83 | 2392 |

| 2/0 | 329 | 24 | 80 | 1.97 | 2943 |

| 3/0 | 413 | 24 | 80 | 2.12 | 3501 |

| 4/0 | 532 | 24 | 80 | 2.31 | 4106 |

| 250 | 608 | 24 | 95 | 2.72 | 5215 |

| 300 | 741 | 24 | 95 | 2.9 | 6162 |

| 350 | 855 | 24 | 95 | 3.04 | 6955 |

| 500 | 1221 | 24 | 95 | 3.46 | 9636 |

- Next: CV-Awa, Power Cable, 0.6/1 Kv, 1/C, Cu/XLPE/PVC/Awa/PVC (IEC 60502-1)

- Previous: Triplex Secondary Urd, Urd Cable, 600 V, Al/XLPE (ANSI/ICEA S-105-692)