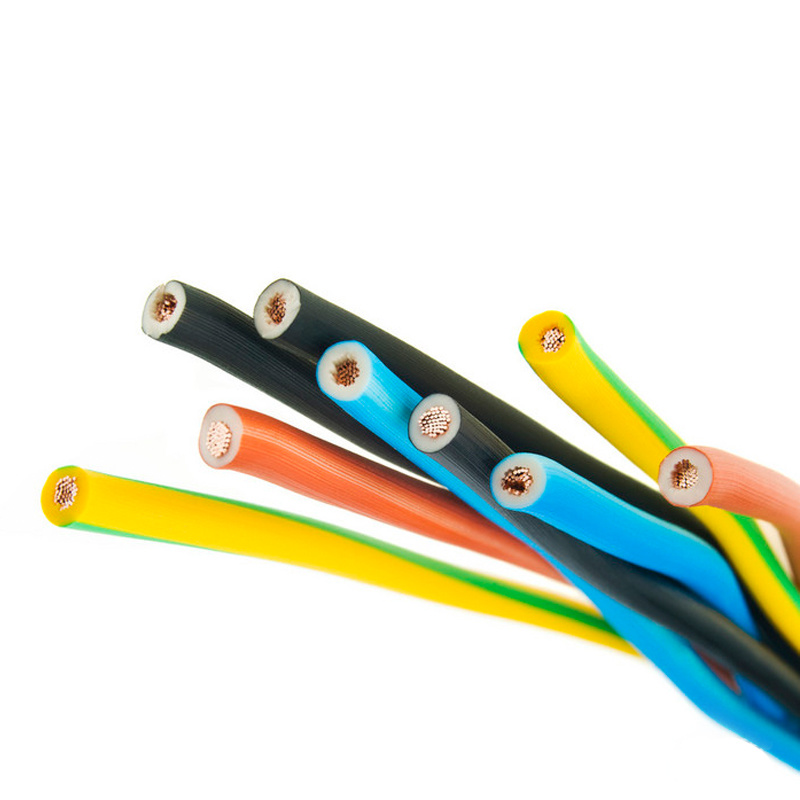

PVC Insulated Wire Thw, Thhn, TF, Tfn Wire

Product Description

Packaging Details

Coils , reels ,drums ,steel-wooden drums.

Port

Qingdao , Shanghai or other port in China

THHN / THWN cable wire

1. SCOPE

1.1 This specification describes single conductor THWN or THHN, a general purpose building wire insulated

with polyvinyl chloride (PVC) and covered with a tough protective sheath of nylon intended for lighting and power

circuits at 600 Volts or less, in residential, commercial and industrial buildings. The wire may be operated at 90°C

maximum continuous temperature in dry locations and 75°C in wet locations and is listed by Underwriters Laboratories

2. APPLICABLE STANDARDS

2.1 The following standards form a part of this specification to the extent specified herein:

2.1.1 Underwriters Laboratories Standard 83 for Thermoplastic Insulated Wires.

2.1.2 Underwriters Laboratories Standard 1063 for Machine-Tool Wires and Cables (Stranded items only) .

2.1.3 Underwriters Laboratories Standard 758 for 105°C Appliance Wiring Materials (Stranded items only).

2.1 .4 CSA Standard C22.2 No. 75 and Electrical Bulletin No. 1451 for Type T90 Nylon or TWN75.

2.1.5 Federal Specification J-C-30B.

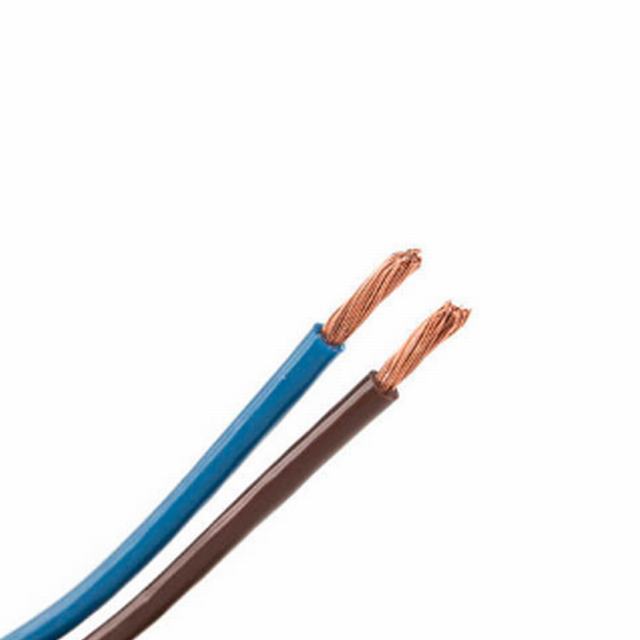

3. CONDUCTORS

3.1 Conductors shall be solid , Class B or Class C stranded, annealed uncoated copper per UL Standards 83 or 1063.

4. INSULATION

4.1 Each conductor shall be insulated with PVC and sheathed with nylon complying with requirements of UL Standard

83 for Types THHN or THWN, UL Standard 1063 for Type MTW and CSA C22.2 No. 75 for T90 Nylon. In addition,

Types THWN or THHN shall comply with the optional Gasoline and Oil Resistant II rating of UL Standard 83. The

insulation on stranded sizes shall also comply with UL requ irements for 105°C Appliance Wiring Material.

4.2 The average thickness of PVC insulation, for a given conductor size, shall be as specified in UL Standard 83 for

Types THWN or THHN. The minimum thickness at any point, of the PVC insulation, shall be not less than 90% of

the specified average thickness. The minimum thickness at any point of the nylon sheath, shall be as specified in

UL Standard 83 for Types THWN or THHN. The PVC insulation shall be applied tightly to the conductor and shall

be free-stripping .

5. IDENTIFICATION

5.1 The wire shall be identified by surface marking indicating manufacturer’s identification, conductor size and metal,

voltage rating, UL Symbol, type designations and optional ratings . The wire shall also be identified as C(UL) Type

T90 Nylon or TWN75, FT1 .

6. TESTS

6.1 Wire shall be tested in accordance with the requirements of UL Standard 83 for Types THWN or THHN wire and

for the optional Gasoline and Oil Resistant II listings; as Type MTW to UL Standard 1063 (stranded items); as

AWM to UL Standard 758 (stranded items); and as C(UL) Type T90 Nylon orTWN75.

- Next: N2xsy 6/10kv, 12/20kv, 18/30kv Cu/XLPE/Cws/Cts/PVC

- Previous: Airdac Sne Cable Concentric Cable 16mm2