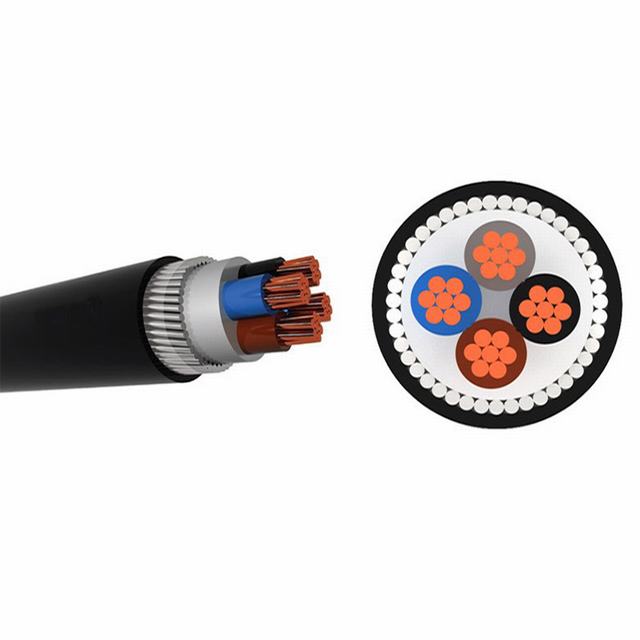

Price Low Voltage 4 Core 95mm XLPE/PVC Insualted Armoured Submarine Power Cable

Product Description

Standard:

IEC60502,and BS6346, VDE, AS/NZS, UL,etc or as customer’s request.

The Rated Voltage(kv):

1st class 0.6/1 1.8/3 3.6/6 6/10 8.7/15 12/20 18/30 21/35

2nd class 1/1 3/3 6/6 8.7/10 12/15 18/20 – 26/35

Application:

Power cable are most suitable for direct burial or for installation on trays or ducts, Where there is

a risk of mechanical damage, armoured cables should be used.

|

TYPE |

NAME |

Main Application |

|

|

CU core |

AL core |

||

|

YJV/YJY |

YJLV/YJLY |

XLPE insulated,PVC/PE sheathed power cable |

For laying indoor ,tunnel,canal and underground. |

|

YJV22/YJV23 |

YJLV22/YJLV23 |

XLPE insulated,steel tape armored, |

For laying indoor ,tunnel,canal and underground. |

|

YJV32/YJV33 |

YJLV32/YJLV33 |

XLPE insulated,thin steel wire armored, |

For laying in shaft,water underground will large difference of level. |

|

YJV42/YJV43 |

YJLV42/YJLV43 |

XLPE insulated,thick steel wire armored, |

For laying in water and seabed. |

Number of cores:

1core 2core 3core 3+1core 4core 4+1core 4+2core 5core and so on.

Nominal Section

Area(mm2) :1.5 2.5 4 6 10 16 25 35 50 70 95 120 150 185 240 300 400 500 630 800

Features:

1). XLPE insulated power cable not only has excellent electric, mechanical properties, but also has powerful resistance against chemical erosion, heat-aging and environmental stress.

2) .Its structures are simple. The long term operating temperature is +90 degrees. It is convenient to use and can be laid with no restriction of different level.

3). Our XLPE cables can be produced according to our specification which is equivalent to IEC 502-1983, and its some indexes are superior to 502-1983.

4). We can design and manufacture special XLPE cable according to the other standards required by the customers.

5).Application: for laying indoor, tunnel, canal and underground.

| Nominal Cross Section |

Diameter of Conductor (Approx.) |

Nominal Insulation thickness |

Nominal Inner Covering thickness |

Nominal Alum Wire dia. |

Nominal Sheath thickness |

Overall Diameter (Approx.) |

| mm² | mm | mm | mm | mm | mm | mm |

| 1×4 | 2.3 | 0.7 | 1 | 0.8 | 1.8 | 10.9 |

| 1×6 | 2.8 | 0.7 | 1 | 0.8 | 1.8 | 11.4 |

| 1×10 | 3.6 | 0.7 | 1 | 0.8 | 1.8 | 12.2 |

| 1×16 | 4.5 | 0.7 | 1 | 0.8 | 1.8 | 13.1 |

| 1×25 | 5.6 | 0.9 | 1 | 0.8 | 1.8 | 14.6 |

| 1×35 | 6.7 | 0.9 | 1 | 1.25 | 1.8 | 16.6 |

| 1×50 | 8 | 1 | 1 | 1.25 | 1.8 | 18.1 |

| 1×70 | 9.4 | 1.1 | 1 | 1.25 | 1.8 | 19.7 |

| 1×95 | 11 | 1.1 | 1 | 1.6 | 1.8 | 22 |

| 1×120 | 12.4 | 1.2 | 1 | 1.6 | 1.8 | 23.6 |

| 1×150 | 13.8 | 1.4 | 1 | 1.6 | 1.8 | 25.4 |

| 1×185 | 15.3 | 1.6 | 1 | 1.6 | 1.8 | 27.4 |

| 1×240 | 17.5 | 1.7 | 1 | 1.6 | 1.9 | 29.9 |

| 1×300 | 19.5 | 1.8 | 1 | 2 | 2 | 33.1 |

| 1×400 | 22.6 | 2 | 1.2 | 2 | 2.2 | 37.3 |

| 1×500 | 25.2 | 2.2 | 1.2 | 2 | 2.3 | 40.5 |

| Nominal Cross Section |

Diameter of Conductor (Approx.) |

Nominal Insulation thickness |

Nominal Inner Covering thickness |

Nominal Steel Wire dia. |

Nominal Sheath thickness |

Overall Diameter (Approx.) |

| mm² | mm | mm | mm | mm | mm | mm |

| 2×1.5 | 1.4 | 0.7 | 1 | 0.8 | 1.8 | 12.8 |

| 2×2.5 | 1.8 | 0.7 | 1 | 0.8 | 1.8 | 13.6 |

| 2×4 | 2.3 | 0.7 | 1 | 0.8 | 1.8 | 14.6 |

| 2×6 | 2.8 | 0.7 | 1 | 1.25 | 1.8 | 16.5 |

| 2×10 | 3.6 | 0.7 | 1 | 1.25 | 1.8 | 18.1 |

| 2×16 | 4.5 | 0.7 | 1 | 1.25 | 1.8 | 19.9 |

| 2×25 | 5.6 | 0.9 | 1 | 1.6 | 1.8 | 23.6 |

| 2×35 | 6.7 | 0.9 | 1 | 1.6 | 1.8 | 25.8 |

| 2×50 | 8 | 1 | 1 | 1.6 | 1.9 | 29 |

| 2×70 | 9.4 | 1.1 | 1 | 2 | 2 .3 | 3.2 |

| 2×95 | 11 | 1.1 | 1.2 | 2.1 | 3 | 7.1 |

| 2×120 | 12.4 | 1.2 | 1.2 | 2 | 2.3 | 40.5 |

| 2×150 | 13.8 | 1.4 | 1.2 | 2.5 | 2.4 | 45.4 |

| 2×185 | 15.3 | 1.6 | 1.4 | 2.5 | 20.6 | 49.9 |

| 2×240 | 17.5 | 1.7 | 1.4 | 2.5 | 20.7 | 55.1 |

| 2×300 | 19.5 | 1.8 | 1.6 | 2.5 | 20.9 | 60.2 |

| 2×400 | 22.6 | 2 | 1.6 | 2.5 | 30.1 | 67.7 |

| Nominal Cross Section |

Diameter of Conductor (Approx.) |

Nominal Insulation thickness |

Nominal Inner Covering thickness |

Nominal Steel Wire dia. |

Nominal Sheath thickness |

Overall Diameter (Approx.) |

| mm² | mm | mm | mm | mm | mm | mm |

| 3×1.5 | 1.4 | 0.7 | 1 | 0.8 | 1.8 | 13.2 |

| 3×2.5 | 1.8 | 0.7 | 1 | 0.8 | 1.8 | 14.1 |

| 3×4 | 2.3 | 0.7 | 1 | 0.8 | 1.8 | 15.2 |

| 3×6 | 2.8 | 0.7 | 1 | 1.25 | 1.8 | 17.1 |

| 3×10 | 3.6 | 0.7 | 1 | 1.25 | 1.8 | 18.9 |

| 3×16 | 4.5 | 0.7 | 1 | 1.25 | 1.8 | 20.8 |

| 3×25 | 5.6 | 0.9 | 1 | 1.6 | 1.8 | 24.7 |

| 3×35 | 6.7 | 0.9 | 1 | 1.6 | 1.8 | 27.2 |

| 3×50 | 8 | 1 | 1 | 1.6 | 1.9 | 30.6 |

| 3×70 | 9.4 | 1.1 | 1 | 2 | 2.1 | 35.2 |

| 3×95 | 11 | 1.1 | 1.2 | 2 | 2.2 | 39.3 |

| 3×120 | 12.4 | 1.2 | 1.2 | 2 | 2.3 | 43 |

| 3×150 | 13.8 | 1.4 | 1.4 | 2.5 | 2.5 | 48.6 |

| 3×185 | 15.3 | 1.6 | 1.4 | 2.5 | 2.7 | 53 |

| 3×240 | 17.5 | 1.7 | 1.4 | 2.5 | 2.8 | 58.5 |

| 3×300 | 19.5 | 1.8 | 1.6 | 2.5 | 3 | 64 |

| 3×400 | 22.6 | 2 | 1.6 | 3.15 | 3.3 | 73.5 |

| Nominal Cross Section |

Diameter of Conductor (Approx.) |

Nominal Insulation thickness |

Nominal Inner Covering thickness |

Nominal Steel Wire dia. |

Nominal Sheath thickness |

Overall Diameter (Approx.) |

||

| mm² | mm | mm | mm | mm | mm | mm | mm | mm |

| 3x 16/10 | 4.5 | 3.6 | 0.7 | 0.7 | 1 | 1.6 | 1.8 | 22.7 |

| 3x 25/16 | 5.6 | 4.5 | 0.9 | 0.7 | 1 | 1.6 | 1.8 | 26.5 |

| 3x 35/16 | 6.7 | 4.5 | 0.9 | 0.7 | 1 | 1.6 | 1.9 | 29 |

| 3x 50/25 | 8 | 5.6 | 1 | 0.9 | 1 | 1.6 | 2.1 | 33 |

| 3x 70/35 | 9.4 | 6.7 | 1.1 | 0.9 | 1.2 | 2 | 2.2 | 38 |

| 3x 95/50 | 11 | 8 | 1.1 | 1 | 1.2 | 2 | 2.3 | 42.4 |

| 3×120/70 | 12.4 | 9.4 | 1.2 | 1.1 | 1.2 | 2 | 2.5 | 48 |

| 3×150/70 | 13.8 | 9.4 | 1.4 | 1.1 | 1.4 | 2.5 | 2.7 | 52 |

| 3×185/95 | 15.3 | 11 | 1.6 | 1.1 | 1.4 | 2.5 | 2.8 | 57.2 |

| 3×240/120 | 17.5 | 12.4 | 1.7 | 1.2 | 1.6 | 2.5 | 3.1 | 64 |

| 3×300/150 | 19.5 | 13.8 | 1.8 | 1.4 | 1.6 | 2.5 | 3.2 | 69.8 |

| Nominal Cross Section |

Diameter of Conductor (Approx.) |

Nominal Insulation thickness |

Nominal Inner Covering thickness |

Nominal Steel Wire dia. |

Nominal Sheath thickness |

Overall Diameter (Approx.) |

| mm² | mm | mm | mm | mm | mm | mm |

| 4×1.5 | 1.4 | 0.7 | 1 | 0.8 | 1.8 | 14 |

| 4×2.5 | 1.8 | 0.7 | 1 | 0.8 | 1.8 | 14.9 |

| 4×4 | 2.3 | 0.7 | 1 | 1.25 | 1.8 | 17 |

| 4×6 | 2.8 | 0.7 | 1 | 1.25 | 1.8 | 18.2 |

| 4×10 | 3.6 | 0.7 | 1 | 1.25 | 1.8 | 20.2 |

| 4×16 | 4.5 | 0.7 | 1 | 1.6 | 1.8 | 23 |

| 4×25 | 5.6 | 0.9 | 1 | 1.6 | 1.8 | 26.7 |

| 4×35 | 6.7 | 0.9 | 1 | 1.6 | 1.9 | 29.5 |

| 4×50 | 8 | 1 | 1 | 2 | 2.1 | 34.2 |

| 4×70 | 9.4 | 1.1 | 1.2 | 2 | 2.2 | 38.8 |

| 4×95 | 11 | 1.1 | 1.2 | 2 | 2.3 | 42.9 |

| 4×120 | 12.4 | 1.2 | 1.4 | 2.5 | 2.5 | 48.6 |

| 4×150 | 13.8 | 1.4 | 1.4 | 2.5 | 2.7 | 53.2 |

| 4×185 | 15.3 | 1.6 | 1.4 | 2.5 | 2.8 | 58.1 |

| 4×240 | 17.5 | 1.7 | 1.6 | 2.5 | 3.1 | 64.8 |

| 4×300 | 19.5 | 1.8 | 1.6 | 2.5 | 3.2 | 70.4 |

| 4×400 | 22.6 | 2 | 1.8 | 3.15 | 3.6 | 81.3 |

Packaging

Packing Details : Packing in wooden drum, iron-wooden drum or as customer’s requirement.

Delivery Details : 15-25 days after place an order.

- Next: LV 1kv PVC Insulated Power Cable

- Previous: House Residential Copper PVC Insualted Flexible Electrical Building Wire