Copper Conductor PVC Insulation Steel Tape Armored Power Cable Nyby

Product Description

Operating Characteristics

Rated voltage: 0.6/1(1.2)kV

Max. Permissible continuous operating temperature of conductor: 70° C

Max. Temperature of conductor during short-circuit (5s max. Duration) shall not exceed:

Nominal cross section of conductor ≤ 300mm2: 160 ° C

Nominal cross section of conductor >300mm2: 140 ° C

The ambient temperature under installation should not be lower than: 0 ° C

The bending radius of cable is recommended as following:

For single core cable: Not less than 15 times of the diameter of cable

For multi-core cable: Not less than 12 times of the diameter of cable

When the armored single core cable used for Alternative Current(AC) system, the armoring material should be non-magnetic.

Kabel NYBY Application:

Distribution power cable for static application, mostly in ground, but also in water, within facilities, in cable canals, in concrete. Used in electric power plants, transformer stations, industrial plants, metropolitan networks and other electric plants. Applied in conditions requiring protection against heavier mechanical damages, but where cables are not exposed to heavier tensile strain.

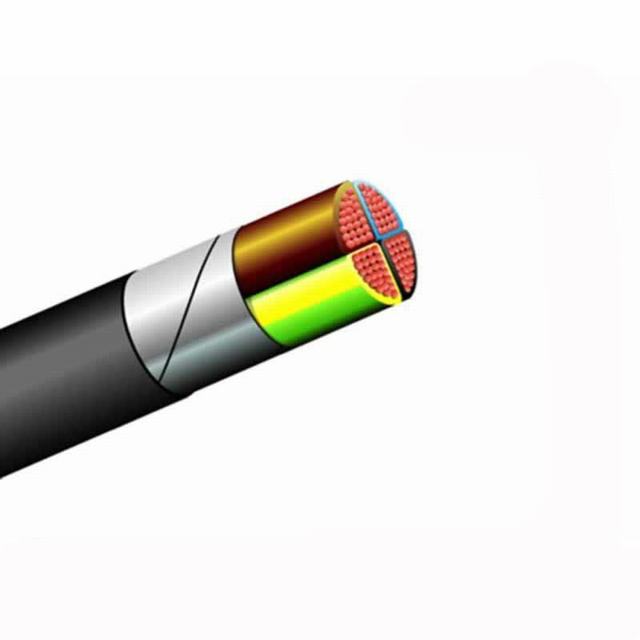

NYBY Cable Construction:

| Conductor: | Cu, class 1 or 2 acc. to HRN HD 383 / IEC 60228 / DIN VDE 0295 |

| class 1: | solid, round (RE) |

| class 2: | multi wire stranded, round (RM) or sector (SM), multi wire exceeding 50 mm² are compacted |

| Insulation: | PVC compound, concentrically stranded cores, colour marked acc. to HRN HD 308 S2 / VDE 0293-308, with or without protective yellow-green conductor |

| Filler: | spouted elastomer or plastomer compound or wrapped thermoplastic tapes |

| Armour: | Wrapping of two galvanized steel tapes |

| Sheath: | PVC compound |

| sheath colour: | black |

NYBY-J / NYBY-O Technical Sheet :

| Number and cross-sectional area of conductor | Approximate overall diameter | Approximate net weight of cables |

Maximum conductor resistance at temperature 20°C |

| n x mm2 | mm | kg/km | Ω/km |

| 2×1,5RE | 13,7 | 297 | 12,1 |

| 2×2,5RE | 14,5 | 342 | 7,41 |

| 2x4RE | 16,2 | 438 | 4,61 |

| 2x6RE | 17,2 | 513 | 3,08 |

| 2x10RE | 18,8 | 651 | 1,83 |

| 2x10RM | 19,4 | 683 | 1,83 |

| 2x16RE | 20,6 | 833 | 1,15 |

| 2x16RM | 21,4 | 881 | 1,15 |

| 2x25RM | 25,4 | 1275 | 0,727 |

| 2x35RM | 27,5 | 1567 | 0,524 |

| 3×1,5RE | 14,2 | 325 | 12,1 |

| 3×2,5RE | 15,0 | 378 | 7,41 |

| 3x4RE | 16,8 | 491 | 4,61 |

| 3x6RE | 17,9 | 584 | 3,08 |

| 3x10RE | 19,6 | 758 | 1,83 |

| 3x10RM | 20,3 | 793 | 1,83 |

| 3x16RE | 21,5 | 990 | 1,15 |

| 3x16RM | 22,4 | 1043 | 1,15 |

| 3x25RM | 26,7 | 1524 | 0,727 |

| 3x35SM | 26,7 | 1644 | 0,524 |

| 3x50SM | 29,7 | 2112 | 0,387 |

| 3x70SM | 33,4 | 2842 | 0,268 |

| 3x95SM | 38,8 | 4110 | 0,193 |

| 3x120SM | 41,6 | 4939 | 0,153 |

| 3x150SM | 46,2 | 6019 | 0,124 |

| 3x185SM | 50,3 | 7302 | 0,0991 |

| 3x240SM | 56,3 | 9339 | 0,0754 |

Parameter of 4 core NYBY cable

| Number and cross-sectional area of conductor | Approximate overall diameter | Approximate net weight of cables |

Maximum conductor resistance at temperature 20°C |

| n x mm2 | mm | kg/km | Ω/km |

| 4×1,5RE | 14,9 | 362 | 12,1 |

| 4×2,5RE | 15,9 | 430 | 7,41 |

| 4x4RE | 17,9 | 565 | 4,61 |

| 4x6RE | 19,1 | 679 | 3,08 |

| 4x10RE | 21,0 | 895 | 1,83 |

| 4x10RM | 21,8 | 937 | 1,83 |

| 4x16RE | 23,2 | 1188 | 1,15 |

| 4x16RM | 24,2 | 1250 | 1,15 |

| 4x25RM | 28,9 | 1837 | 0,727 |

| 4x35SM | 29,7 | 2098 | 0,524 |

| 4x50SM | 33,6 | 2756 | 0,387 |

| 4x70SM | 38,6 | 4017 | 0,268 |

| 4x95SM | 43,7 | 5306 | 0,193 |

| 4x120SM | 47,5 | 6437 | 0,153 |

| 4x150SM | 51,7 | 7756 | 0,124 |

| 4x185SM | 57,0 | 9531 | 0,0991 |

| 4x240SM | 63,4 | 12128 | 0,0754 |

| 3x35SM/16RE | 26,7 | 1804 | 0,524/1,15 |

| 3x50SM/25RM | 32,2 | 2455 | 0,387/0,727 |

| 3x70SM/35SM | 37,2 | 3334 | 0,268/0,524 |

| 3x95SM/50SM | 42,2 | 4772 | 0,193/0,387 |

| 3x120SM/70SM | 45,1 | 5806 | 0,153/0,268 |

| 3x150SM/70SM | 49,7 | 6865 | 0,124/0,268 |

| 3x185SM/95SM | 54,1 | 8442 | 0,0991/0,193 |

| 3x240SM/120SM | 60,8 | 10759 | 0,0754/0,153 |

Parameter of 5 core NYBY power and chontrol cable

| Number and cross-sectional area of conductor | Approximate overall diameter | Approximate net weight of cables |

Maximum conductor resistance at temperature 20°C |

| n x mm2 | mm | kg/km | Ω/km |

| 5×1,5RE | 15,8 | 410 | 12,1 |

| 5×2,5RE | 16,8 | 489 | 7,41 |

| 5x4RE | 19,1 | 654 | 4,61 |

| 5x6RE | 20,5 | 796 | 3,08 |

| 5x10RE | 22,6 | 1060 | 1,83 |

| 5x10RM | 23,4 | 1108 | 1,83 |

| 5x16RE | 25,0 | 1420 | 1,15 |

| 5x16RM | 26,2 | 1497 | 1,15 |

| 5x25RM | 31,4 | 2213 | 0,727 |

| 5x35RM | 34,6 | 2829 | 0,524 |

| 5x50RM | 41,2 | 4147 | 0,387 |

| 5x70RM | 45,2 | 5391 | 0,268 |

| 7×1,5RE | 16,7 | 470 | 12,1 |

| 7×2,5RE | 17,8 | 570 | 7,41 |

| 10×1,5RE | 19,6 | 618 | 12,1 |

| 10×2,5RE | 21,2 | 763 | 7,41 |

| 12×1,5RE | 20,1 | 668 | 12,1 |

| 12×2,5RE | 21,7 | 831 | 7,41 |

| 14×1,5RE | 20,9 | 729 | 12,1 |

| 14×2,5RE | 22,5 | 912 | 7,41 |

| 16×1,5RE | 21,7 | 797 | 12,1 |

| 16×2,5RE | 23,5 | 1005 | 7,41 |

| 19×1,5RE | 22,6 | 877 | 12,1 |

| 19×2,5RE | 24,5 | 1117 | 7,41 |

| 24×1,5RE | 25,6 | 1069 | 12,1 |

| 24×2,5RE | 27,8 | 1368 | 7,41 |

| 30×1,5RE | 26,8 | 1222 | 12,1 |

| 30×2,5RE | 29,4 | 1597 | 7,41 |

| 37×1,5RE | 28,5 | 1412 | 12,1 |

| 37×2,5RE | 31,4 | 1864 | 7,41 |

| 48×1,5RE | 32,1 | 1752 | 12,1 |

| 48×2,5RE | 35,8 | 2365 | 7,41 |

| 61×1,5RE | 35,0 | 2129 | 12,1 |

- Next: 0.6/1kv Nyy-J Nyy-O Copper PVC Insulation PVC Sheath Power Cable

- Previous: DIN VDE0276-603 Standard Copper Electrical Kabel Nyy Power Cable