USA Sizes ASTM B399 All Aluminum Alloy Condcutor AAAC Greeley

Quick Details

Product Details

General:

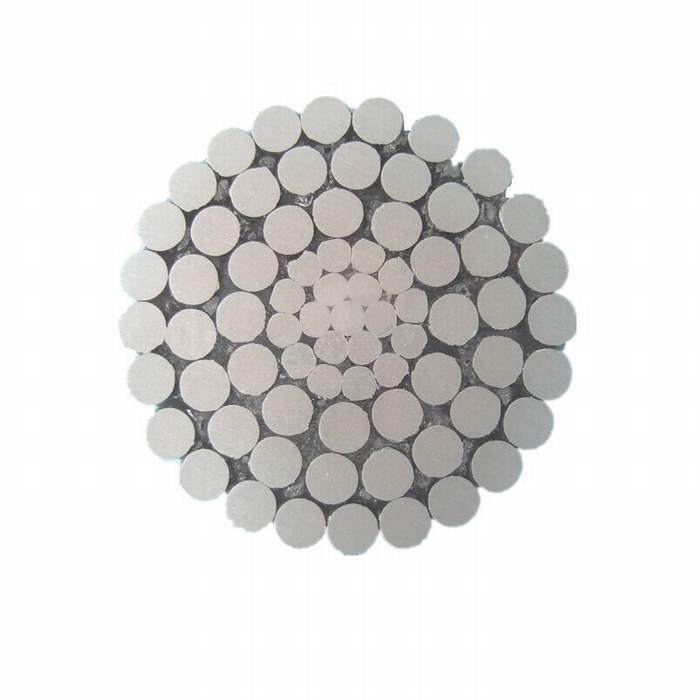

These conductors are formed by several aluminium alloy wires , stranded in concentric layers.The centre wire or wires which form the core are made of alloy.Normally the compositions of these conductors are the same as the ones pertaining to the aluminium-steel conductors.In the case of alloy conductors.All the wire have the same nominal diameter.The diameter of the alloy wires can be the same or different.The basic composition of this alloy pertains to the Aluminium-Magnesium-Silicon group.Which is also known in Europe as Almelec or Aldrey.After their drawing they must undergo a thermal treatment at a temperature of approximately 170°c.

Properties:

As regards aluminium, the wires of this alloy have a double tensile strength .Its electrical conductivity is 15% lower(53% instead of 61%) and the weight is the same.By making use of these characteristics, in many cases an alloy conductor can replace the Aluminium Conductors Steel reinforced with a similar installation cost.

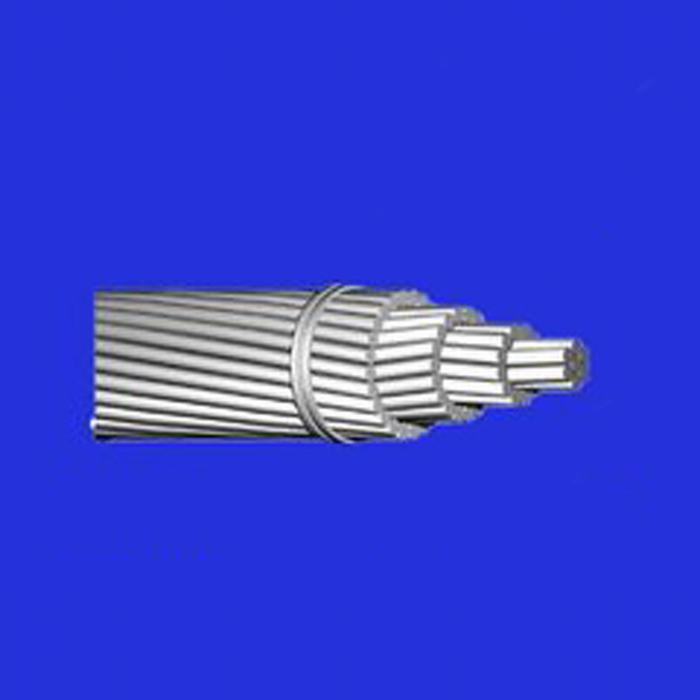

Main applications:

Low, medium ,high and very high voltages transmission lines.

Composition:

| Composition | Final modulus of elasticity mpa | Coefficient of linear expansion/°c |

| 37 61 |

57000 54000 |

23×10 -6 23×10 -6 |

Technical characteristics

| Code | Conductor size | Stranding | Sectional area | Diameter of Condcutor | Linear mass | Rated strength | D.C.Resistance at 20ºC |

| AWG(MCM) | No./mm | mm2 | mm | kg/km | kgf | Ω/km | |

| Greeley | 927.2 | 37/4.02 | 469.80 | 28.14 | 1287 | 13868 | 0.07133 |

| 1000.0 | 37/4.18 | 506.70 | 29.24 | 1388 | 14887 | 0.06597 | |

| 1077.4 | 61/3.18 | 547.30 | 30.42 | 1496 | 15907 | 0.06120 | |

| 1165.1 | 61/3.51 | 590.20 | 31.59 | 1617 | 17233 | 0.05675 | |

| 1250.0 | 61/3.63 | 633.30 | 32.67 | 1733 | 18367 | 0.05306 | |

| 1259.6 | 61/3.65 | 638.30 | 32.85 | 1748 | 18558 | 0.05248 | |

| 1348.8 | 61/3.78 | 684.50 | 34.02 | 1891 | 19884 | 0.04893 | |

| 1500.0 | 61/3.98 | 760.00 | 35.82 | 2081 | 22142 | 0.04414 | |

| 1750.0 | 61/4.30 | 886.70 | 38.70 | 2429 | 25816 | 0.03781 |

Production Process

- Next: Thal Thermo-Resistance Aluminum Alloy Conductor

- Previous: USA Sizes ASTM B399 All Aluminum Alloy Condcutor AAAC Ames