Overhead ACSR, AAC, AAAC, Acss/Tw, Accc, Aacsr, Acar, Opgw Bare Conductor

Product Description

AAAC (All Aluminum Alloy Conductor) referred to have higher strength but lower conductivity than pure aluminum. Being lighter, alloy conductors can sometimes be used to advantage in place of the more conventional ACSR;

Having lower breaking loads than the latter, their use becomes particularly favourable when ice and win loadings are low.

We can supply this conductor according to different recognized standards, such as BS EN50182, IEC61089, ASTM B399DIN 48, customer special specification also can be satisfied.

2. Applications:

Used as bare overhead conductor for primary and secondary distribution. Designed utilizing a high-strength aluminum-alloy to achieve a high strength-to-weight ratio; affords good sag characteristics. Aluminum-alloy gives 6201-T81 gives AAAC higher resistance to corrosion than ACSR.

3. Standards&Specifications:

All Aluminium Alloy Conductor-AAAC (DIN 48201 Standard Sizes)

AAAC Wire_All Aluminum Alloy Conductor_Aerial Conductor_All Aluminum ALLOY Conductor_All Aluminum Cable_AAC_Overhaed Conductor

Factory PRICE

FREE SAMPLE

Product Description

AAC AAAC ACSR AACSR ACAR ACS AL BARE CONDUCTOR

AAC–Aluminum Strand Conductor

Applications

Stranded 1350 aluminum conductors shown in this section of data are classified as follows:

Class AA For bare conductors usually used in overhead lines.

Class A For conductors to be covered with weather-resistant materials and for bare conductors where greater flexibility is required.

Compact strand conductor for use in bare overhead applications or for use with weather-resistant coverings or insulations is also available.

Classes refer to stranding and are an indication of relative conductor flexibility, AA being the least flexible, C the most flexible.

Construction

Aluminum alloy 1350-H19 wires, concentrically stranded.

Specifications

AAC bare conductors meet or exceed the following ASTM specifications :

B-230 Aluminum Wire, 1250-H19 for Electrical Purposes

B-231 Aluminum Conductors, Concentric-Lay-Stranded

B-400 Compact Round Concentric-Lay-Stranded Aluminum 1350 Conductors

ACSR–Aluminum Strand Conductor Steel Reinforced

Applications

Used as bare overhead transmission cable and as primary and secondary distribution cable. ACSR offers optimal strength for line design. Variable steel core stranding enables desired strength to be achieved without sacrificing ampacity.

Construction

Aluminum alloy 1350-H-19 wires, concentrically stranded about a steel core. Core wire for ACSR is available with class A, B, or C galvanizing; ""aluminized"" aluminum coated (AZ); or aluminum-clad (AW) – please see our ACSR/AW spec for more information. Additional corrosion protection is available through the application of grease to the corer or infusion of the complete cable with grease.

Specifications

ACSR bare conductor meets or exceeds the following ASTM specifications:

B-230 Aluminum Wire, 1350-H19 for Electrical Purposes

B-231 Aluminum Conductors, Concentric-Lay-Stranded

B-232 Aluminum Conductors, Concentric-Lay-Stranded, Coated Steel Reinforced (ACSR)

B-341 Aluminum-Coated Steel Core Wire for Aluminum Conductors, Steel Reinforced (ACSR/AZ)

B-502 Aluminum-Coated Steel Core Wire for Aluminum Conductors, Steel Reinforced (ACSR/AW)

B-498 Zinc-Coated Steel Core Wire for Aluminum Conductors, Steel Reinforced (ACSR/AZ)

B-500 Zinc Coated and Aluminum Coated Stranded Steel Core for Aluminum Conductors, Steel Reinforced (ACSR)

AAAC 6201–Aluminum Alloy Bare Conductor

Applications

Used as bare overhead conductor for primary and secondary distribution. Designed utilizing a high-strength aluminum alloy to achieve a high strength-to-weight ratio; affords better sag characteristics. Aluminum alloy gives AAAC higher resistance to corrosion than ACSR.

Construction

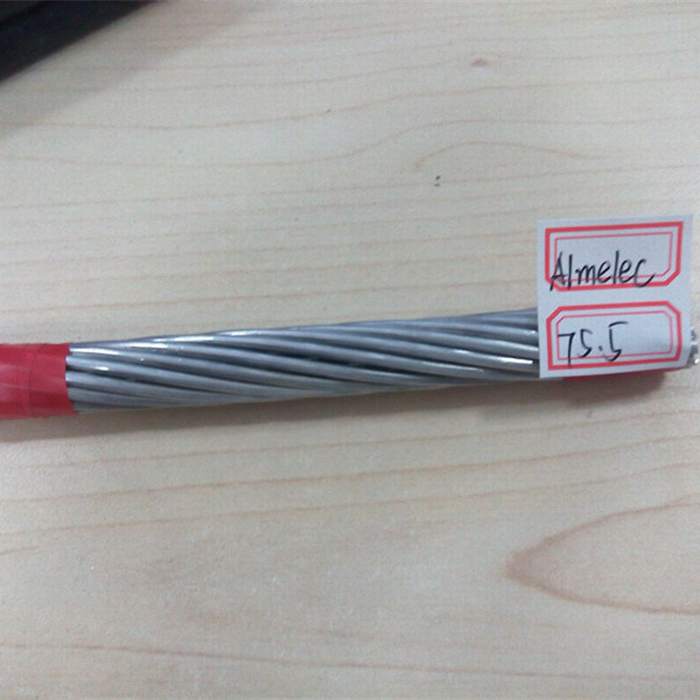

Standard 6201-T81 high strength aluminum conductors, conforming to ASTM Specification B-399, are concentric-lay- stranded, similar in construction and appearance to 1350 grade aluminum conductors. Standard 6201 alloy conductors are similar to other alloy conductors commercially known as Ardival, Aldrey or Almelec. They were developed to fill the need for an economical conductor for overhead applications requiring higher strength than that obtainable with 1350 grade aluminum conductors, but without a steel core. The DC resistance at 20°C of the 6201-T81 conductors and of the standard ACSRs of the same diameter are approximately the same. Conductors of the 6201-T81 alloys are harder and, therefore, have a greater resistance to abrasion than conductors of 1350-H19 grade aluminum.

Specifications

AAAC bare conductor meets or exceeds the following ASTM specifications :

B-398 Aluminum Alloy 6201-T81 Wire for Electrical Purposes

B-399 Concentric-Lay-Stranded 6201-T81 Aluminum Alloy Conductors.

ACAR–Aluminum Conductor Aluminum Alloy Reinforced

Applications

ACAR cables are used for overhead transmission and distribution lines.

Construction

Concentric-stranded cable formed by a core of 6201-T81 aluminum alloy wires surrounded by 1350 H-19 aluminum wires concentrically stranded over the alloy core. Some designs have 1350 aluminum wires and 6201 alloy wires intercalated in the same layer.

Features

Very good ratio Tensile Strength to Weight. Highly resistant to corrosion.

Standards

- ASTM B-524

Notes

Current Carrying Capacity is based on 77oF (25oC) ambient temperature,

167oF (75oC) conductor temperature, 2 ft/sec (0.6 m/s) wind velocity,

0.5 Cable emissivity, sun 96 watts/sq.ft (1000 watts/mo), at sea level

| Nominal Area | Conductor Construction | Calculated Area | Overall Diameter | Weight | DC Resistance at 20 |

| mm2 | No./mm | mm2 | mm | kg/km | Ω/km |

| 16 | 7/1.70 | 15.9 | 5.1 | 43.5 | 2.091 |

| 25 | 7/2.10 | 24.2 | 6.3 | 66.4 | 1.370 |

| 35 | 7/2.50 | 34.4 | 7.5 | 94.1 | 0.9669 |

| 50 | 7/3.00 | 49.5 | 9.0 | 135 | 0.6714 |

| 50 | 19/1.80 | 48.3 | 9.0 | 133 | 0.6905 |

| 70 | 19/2.10 | 65.8 | 10.5 | 181 | 0.5073 |

| 95 | 19/2.50 | 93.3 | 12.5 | 257 | 0.358 |

| 120 | 19/2.80 | 117 | 14 | 322 | 0.2854 |

| 150 | 37/2.25 | 147 | 15.7 | 406 | 0.2274 |

| 185 | 37/2.50 | 182 | 17.5 | 501 | 0.1842 |

| 240 | 61/2.25 | 243 | 20.2 | 671 | 0.1383 |

| 300 | 61/2.50 | 299 | 22.5 | 828 | 0.1120 |

| 400 | 61/2.89 | 400 | 26.0 | 1,106 | 0.0838 |

| 500 | 61/3.23 | 500 | 29.1 | 1382 | 0.06709 |

| 625 | 91/2.96 | 626 | 32.6 | 1,735 | 0.05367 |

| 800 | 91/3.35 | 802 | 36.9 | 2,222 | 0.0419 |

| 1000 | 91/3.74 | 1,000 | 41.1 | 2,770 | 0.03362 |

| ALUMINIUM ALLOY CONDUCTOR ASTM B399 | |||||||||

| Code Name | Area | Size&Stranding of ACSR with equal diameter | No. and diameter | Overall diameter | Weight | Nominal breaking load | MAX .DC resistance at 20ºC | ||

| Nominal | Actual | AWG or MCM | Al/St | ||||||

| MCM | mm2 | mm | mm | kg/km | kN | ohm/km | |||

| AKRON | 30.58 | 15.48 | 6 | 6/1 | 7/1.68 | 5.04 | 42.7 | 4.92 | 0.3966 |

| ALTON | 48.69 | 24.71 | 4 | 6/1 | 7/2.12 | 6.35 | 68 | 7.84 | 0.3811 |

| AMES | 77.47 | 39.22 | 2 | 6/1 | 7/2.67 | 8.02 | 108 | 12.45 | 0.3671 |

| AZUSA | 123.3 | 62.38 | 1/0 | 6/1 | 7/3.37 | 10.11 | 172 | 18.97 | 0.3524 |

| ANAHEIM | 155.4 | 78.65 | 2/0 | 6/1 | 7/3.78 | 11.35 | 217 | 23.93 | 0.3448 |

| AMHERST | 195.7 | 99.22 | 3/0 | 6/1 | 7/4.25 | 12.75 | 273 | 30.18 | 0.3375 |

| ALLIANCE | 246.9 | 125.1 | 4/0 | 6/1 | 7/4.77 | 14.31 | 345 | 38.05 | 0.3306 |

| BUTTE | 312.8 | 158.6 | 266.8 | 26/7 | 19/3.26 | 16.3 | 437 | 48.76 | 0.3196 |

| CANTON | 394.5 | 199.9 | 366.4 | 26/7 | 19/3.66 | 18.3 | 551 | 58.91 | 0.3124 |

| CAIRO | 465.4 | 235.8 | 397.5 | 26/7 | 19/3.98 | 19.88 | 650 | 69.48 | 0.3071 |

| DARIEN | 559.5 | 283.5 | 477 | 26/7 | 19/4.36 | 21.79 | 781 | 83.52 | 0.3014 |

| ELGIN | 652.4 | 330.6 | 556.5 | 26/7 | 19/4.71 | 23.54 | 911 | 97.42 | 0.2966 |

| FLINT | 740.8 | 375.3 | 636 | 26/7 | 37/3.59 | 25.16 | 1035 | 108.21 | 0.2917 |

| GREELY | 927.2 | 469.8 | 795 | 26/7 | 37/4.02 | 28.14 | 1295 | 135.47 | 0.2846 |

| Area | Stranding and wire diameter | Approx. overall diameter | Weight | Nominal Breaking Load | MAX .DC resistance at 20ºC | |

| Nominal | Actual | |||||

| AWGorMCM | (mm2) | (mm) | (mm) | (kg/km) | (kN) | (ohm/km) |

| 6 | 13.30 | 7/1.554 | 4.67 | 37 | 4.22 | 2.5199 |

| 4 | 21.15 | 1/1.961 | 5.89 | 58 | 6.71 | 1.5824 |

| 2 | 33.63 | 7/2.474 | 7.42 | 93 | 10.68 | 0.9942 |

| 1/0 | 53.48 | 7/3.119 | 9.36 | 148 | 16.97 | 0.6256 |

| 2/0 | 67.42 | 7/3.503 | 10.51 | 186 | 20.52 | 0.4959 |

| 3/0 | 85.03 | 7/3.932 | 11.8 | 234 | 25.86 | 0.3936 |

| 4/0 | 107.23 | 7/4.417 | 13.26 | 296 | 32.63 | 0.3119 |

| 250 | 126.66 | 19/2.913 | 14.57 | 349 | 38.93 | 0.2642 |

| 300 | 152.1 | 19/3.193 | 15.97 | 419 | 46.77 | 0.2199 |

| 350 | 177.35 | 19/3.447 | 17.24 | 489 | 52.25 | 0.1887 |

| 400 | 202.71 | 19/3.686 | 18.43 | 559 | 59.74 | 0.1650 |

| 450 | 228 | 19/3.909 | 19.55 | 629 | 67.19 | 0.1467 |

| 500 | 253.35 | 19/4.120 | 20.60 | 698 | 74.64 | 0.1321 |

| 550 | 278.60 | 37/3.096 | 21.67 | 768 | 83.80 | 0.1202 |

| 600 | 303.80 | 37/3.233 | 22.63 | 838 | 91.38 | 0.1102 |

| 650 | 329.25 | 37/3.366 | 23.56 | 908 | 97.94 | 0.1016 |

| 700 | 354.55 | 37/3.493 | 24.45 | 978 | 102.20 | 0.0944 |

| 750 | 380.20 | 37/3.617 | 25.32 | 1049 | 109.60 | 0.0880 |

| 800 | 405.15 | 37/3.734 | 26.14 | 1117 | 116.80 | 0.0826 |

| 900 | 456.16 | 37/3.962 | 27.73 | 1258 | 131.50 | 0.0733 |

| 1000 | 506.71 | 37/4.176 | 29.23 | 1399 | 146.10 | 0.0660 |

| 1100 | 557 | 61/3.41 | 30.69 | 1537 | 162.16 | 0.0589 |

| 1200 | 608 | 61/3.56 | 32.04 | 1677 | 176.75 | 0.0541 |

| 1300 | 659 | 61/3.71 | 33.39 | 1816 | 191.95 | 0.0498 |

| 1400 | 709 | 61/3.85 | 34.65 | 1955 | 206.72 | 0.0463 |

| 1500 | 760 | 61/3.98 | 35.82 | 2095 | 220.90 | 0.0441 |

| 1600 | 811 | 61/4.12 | 37.08 | 2236 | 235.57 | 0.0405 |

| 1700 | 861 | 61/4.24 | 38.16 | 2374 | 250.72 | 0.0382 |

| 1800 | 912 | 61/4.36 | 39.28 | 2514 | 265.11 | 0.03693 |

| 1900 | 963 | 91/3.67 | 40.37 | 2655 | 277.10 | 0.03411 |

| 2000 | 1013 | 91/3.76 | 41.4 | 2793 | 292.41 | 0.03243 |

| ALUMINIUM ALLOY CONDUCTOR BSEN50183 | |||||||

| Code Name | Calculated Area | No. Of Wires | Diameter | Weight | Rated Strength | MAX .DC resistance at 20ºC | |

| Wire | Cond. | ||||||

| mm2 | mm | mm | kg/km | Kn | ohm/km | ||

| Box | 18.8 | 7 | 1.85 | 5.55 | 51.4 | 5.55 | 1.748 |

| Acacia | 23.8 | 7 | 2.08 | 6.24 | 64.9 | 7.02 | 1.3828 |

| Almond | 30.1 | 7 | 2.34 | 7.02 | 82.2 | 8.88 | 1.0926 |

| Cedar | 35.5 | 7 | 2.54 | 7.62 | 96.8 | 10.46 | 0.9273 |

| Deodar | 42.2 | 7 | 2.77 | 8.31 | 115.2 | 12.44 | 0.7797 |

| Fir | 47.8 | 7 | 2.95 | 8.85 | 130.6 | 14.11 | 0.6875 |

| Hazel | 59.9 | 7 | 3.3 | 9.9 | 163.4 | 17.66 | 0.5494 |

| Pine | 71.6 | 7 | 3.61 | 10.8 | 195.6 | 21.14 | 0.4591 |

| Holly | 84.1 | 7 | 3.91 | 11.7 | 229.5 | 24.79 | 0.3913 |

| Willow | 89.7 | 7 | 4.04 | 12.1 | 245 | 26.47 | 0.3665 |

| Oak | 118.9 | 7 | 4.65 | 14 | 324.5 | 35.07 | 0.2767 |

| Mulberry | 150.9 | 19 | 3.18 | 15.9 | 414.3 | 44.52 | 0.2192 |

| Ash | 180.7 | 19 | 3.48 | 17.4 | 496.1 | 53.31 | 0.183 |

| Elm | 211 | 19 | 3.76 | 18.8 | 579.2 | 62.24 | 0.1568 |

| Poplar | 239.4 | 37 | 2.87 | 20.1 | 659.4 | 70.61 | 0.1387 |

| Sycamore | 303.2 | 37 | 3.23 | 22.6 | 835.2 | 89.4 | 0.1095 |

| Upas | 362.1 | 37 | 3.53 | 24.7 | 997.5 | 106.82 | 0.0917 |

| Yew | 479 | 37 | 4.06 | 28.4 | 1319.6 | 141.31 | 0.0693 |

| Totara | 498.1 | 37 | 4.14 | 29 | 1372.1 | 146.93 | 0.0666 |

| Rubus | 586.9 | 61 | 3.5 | 31.5 | 1622 | 173.13 | 0.0567 |

| Sorbus | 659.4 | 61 | 3.71 | 33.4 | 1822.5 | 194.53 | 0.0505 |

| Araucaria | 821.1 | 61 | 4.14 | 37.3 | 2269.4 | 242.24 | 0.0406 |

| Redwood | 996.2 | 61 | 4.56 | 41 | 2753.2 | 293.88 | 0.0334 |

| ALUMINIUM ALLOY CONDUCTOR BS 3242 | |||||||

| Code Name | Calculated Area | No. Of Wires | Diameter | Weight | Rated Strength | MAX .DC resistance at 20ºC | |

| Wire | Cond. | ||||||

| mm2 | mm | mm | kg/km | Kn | ohm/km | ||

| Box | 15 | 7/1.85 | 18.82 | 5.55 | 51 | 537 | 1.7495 |

| Acacia | 20 | 7/2.08 | 23.79 | 6.24 | 65 | 680 | 1.384 |

| Almond | 25 | 7/2.34 | 30.1 | 7.02 | 82 | 861 | 1.0934 |

| Cedar | 30 | 7/2.54 | 35.47 | 7.62 | 97 | 1014 | 0.9281 |

| – | 35 | 7/2.77 | 42.18 | 8.31 | 115 | 1205 | 0.7804 |

| Fir | 40 | 7/2.95 | 47.87 | 8.85 | 131 | 1367 | 0.688 |

| Hazel | 50 | 7/3.30 | 59.87 | 9.9 | 164 | 1711 | 0.5498 |

| Pine | 60 | 7/3.61 | 71.65 | 10.83 | 196 | 2048 | 0.4594 |

| – | 70 | 7/3.91 | 84.05 | 11.73 | 230 | 2402 | 0.3917 |

| Willow | 75 | 7/4.04 | 89.73 | 12.12 | 245 | 2565 | 0.3669 |

| – | 80 | 7/4.19 | 96.52 | 12.57 | 264 | 2758 | 0.3441 |

| – | 90 | 7/4.44 | 108 | 13.32 | 298 | 3112 | 0.3023 |

| Oak | 100 | 7/4.65 | 118.9 | 13.95 | 325 | 3398 | 0.2769 |

| – | 100 | 19/2.82 | 118.7 | 14.1 | 326 | 3393 | 0.2787 |

| Mulbery | 125 | 19/3.18 | 150.9 | 15.9 | 415 | 4312 | 0.2192 |

| Ash | 150 | 19/3.48 | 180.7 | 17.4 | 497 | 5164 | 0.1831 |

| Elm | 175 | 19/3.76 | 211 | 18.8 | 580 | 6030 | 0.1568 |

| Poplar | 200 | 37/2.87 | 239.4 | 20.09 | 659 | 8841 | 0.1385 |

| – | 225 | 37/3.05 | 270.3 | 21.35 | 744 | 7724 | 0.1227 |

| Sycamore | 250 | 37/3.22 | 303.2 | 22.54 | 835 | 8664 | 0.1093 |

| Upas | 300 | 37/3.53 | 362.1 | 24.71 | 997 | 10350 | 0.09156 |

| Walnut | 350 | 37/3.81 | 421.8 | 26.67 | 1162 | 12053 | 0.0786 |

| Yew | 400 | 37/4.06 | 479 | 28.42 | 1319 | 13685 | 0.06921 |

| Totara | 425 | 37/4.14 | 498.1 | 28.98 | 1372 | 14233 | 0.06656 |

| Rubus | 500 | 61/3.50 | 586.9 | 31.5 | 1620 | 16771 | 0.05662 |

| Araucaria | 700 | 61/4.14 | 821.1 | 37.26 | 2266 | 23450 | 0.04047 |

- Next: Electric Hard Drawn Aluminum Conductor AAC Cable with ISO Certificate

- Previous: Customized Yjv Yjv22 Yjv32 V Low Voltage Types of Armored Cable Copper Ground Cable 4*25mm2