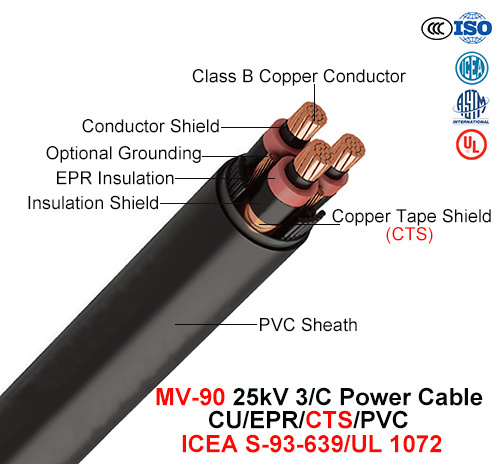

Mv-90, Power Cable, 25 Kv, 3/C, Cu/Epr/Cts/PVC (ICEA S-93-639/NEMA WC71/UL 1072)

Product Description

Features

UL Listed as MV-105. Rated as Sunlight Resistance for CT use, 1/0 AWG and larger. Oil Resistance I jacket. True Triple extrusion system and closed handling raw materials system, to eliminate any contact with ambient, until extrusion process ends.

Application

Primary power and distribution circuits in industrial and commercial installations, power circuits in generating plants where line to ground fault current are within shield capabilities. May be used in wet or dry locations, installed in raceways, duct, and open air, aerially or directly buried where permitted by NEC.

Standards

UL 1072: Medium Voltage Power Cables.

ICEA S-93-639/NEMA WC74: 5 – 46 kV Shielded Power Cables.

ICEA S-97-682: Standard for Utility Shielded. Power Cables Rated 5 – 46 kV.

AEIC CS8: Specification for Extruded Dielectric, Shielded Power Cables Rated 5 – 46 kV.

Specifications

Maximum operating voltage: 5 kV to 35 kV 100% and 133% IL.

Maximum conductor operation temperatures: Wet and dry locations: Normal: 105 °C, Emergency: 140 °C, Short Circuit: 250 °C

Engineering Information

1. Conductor: Soft annealed uncoated copper compacted Class B per ASTM B496 or hard drawn Aluminum-1350 compacted Class B per ASTM B400.

2. Conductor Shield: Semi conducting cross-linked polyethylene (XLPE).

3. Insulation: Thermoset ethylene propylene rubber (EPR). On request, Amorphous EPR.

4. Insulation Shield: Semi conducting cross-linked polyethylene (XLPE).

5. Phase ID: Colored strings (black, red and blue yarns.)

6. Metallic Shield: Soft annealed uncoated copper tape, 5 mil thick, 25% minimum overlap.

7. Grounding (Optional): One or three soft annealed bare copper or covered conductors cabled with phase conductors.

8. Assembly: Conductors cabled with non hygroscopic fillers, as required and binder tape.

9. Jacket: Black sunlight resistance and flame retardant polyvinyl chloride (PVC) compound.

| 100% Insulation Levels (260 mil) | 133% Insulation Levels (320 mil) | |||||||||

| Size | Number of Strands | Conductor Nominal | Jacket Thickness | Approximate Outside Diameter | Approximate Net Weight | Jacket Thickness | Approximate Outside Diameter | Approximate Net Weight | ||

| Copper | Aluminum | Copper | Aluminum | |||||||

| AWG of kcmil | in | mil | in | lb/kft | mil | in | lb/kft | |||

| 1 | 19 | 0.3 | 110 | 2.33 | 2970 | 2414 | – | – | – | – |

| 1/0 | 19 | 0.34 | 110 | 2.41 | 3290 | 2588 | 110 | 2.73 | 3886 | 3184 |

| 2/0 | 19 | 0.38 | 110 | 2.5 | 3675 | 2791 | 140 | 2.88 | 4469 | 3585 |

| 3/0 | 19 | 0.42 | 110 | 2.65 | 4272 | 3157 | 140 | 2.98 | 5002 | 3887 |

| 4/0 | 19 | 0.48 | 140 | 2.83 | 5032 | 3628 | 140 | 3.10 | 5613 | 4209 |

| 250 | 37 | 0.52 | 140 | 2.95 | 5622 | 3961 | 140 | 3.22 | 6224 | 4563 |

| 300 | 37 | 0.57 | 140 | 3.06 | 6264 | 4272 | 140 | 3.33 | 6885 | 4894 |

| 350 | 37 | 0.62 | 140 | 3.16 | 6902 | 4576 | 140 | 3.42 | 7541 | 5216 |

| 400 | 37 | 0.66 | 140 | 3.25 | 7570 | 4914 | 140 | 3.52 | 8226 | 5570 |

| 500 | 37 | 0.74 | 140 | 3.41 | 8793 | 5472 | 140 | 3.68 | 9479 | 6158 |

| 600 | 61 | 0.81 | 140 | 3.6 | 10059 | 6072 | 140 | 3.94 | 10961 | 6974 |

| 750 | 61 | 0.91 | 140 | 3.88 | 11993 | 7016 | 140 | 4.15 | 12761 | 7784 |

- Next: Mv-90, Power Cable, 2.4 Kv, 1/C, Cu/XLPE/PVC (ICEA S-96-659/NEMA WC71/UL 1072)

- Previous: Na2xsey, Power Cable, 8.7/15 Kv, 3/C, Al/XLPE/Cws/PVC (DIN VDE 0276-620)