Low Voltage XLPE Swa Steel Wire Armoured Cable

Product Description

1. CE, ISO 9001 Certificaes

2. More than 23 years experiences

3. Professional Manufacturer with Factory located in Henan Province.

4. Quick response and fast delivery.

6.35/11kV CU/XLPE/PVC(or PE) Power Cable

1. Description

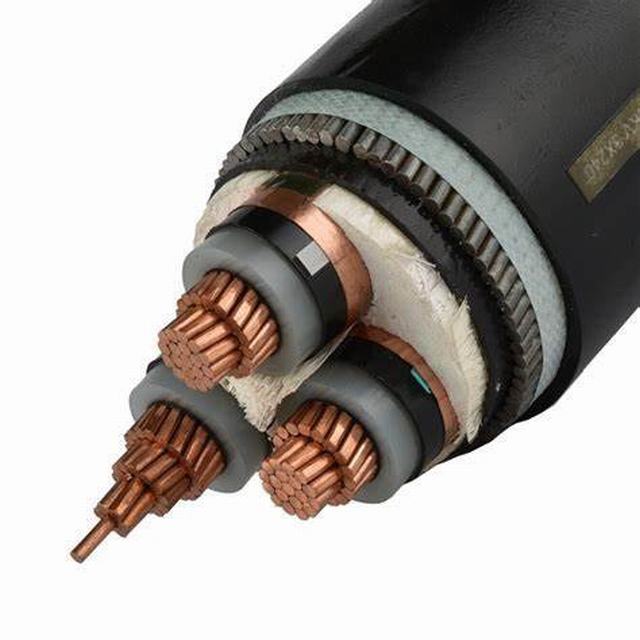

Construction: Compacted stranded circular copper conductor, extruded semi-conducting compound as conductor shield, cross-linked polyethylene (XLPE) insulation, semi-conducting compound as insulation shield, copper tape or combination of copper wire and tape as metallic screen, three cores assembled together with non-hygroscopic

polypropylene filler, wrapped with binder tape, PVC or PE outer sheath.

| Chinese Type |

Description |

Core qty | Conductors range |

| YJV | Copper conductor, XLPE insulation, PVC outer sheath Power Cable | 1 or 3 | 25~800mm2 |

| YJY |

Copper conductor, XLPE insulation, PE outer sheath Power Cable |

1 or 3 |

25~800mm2 |

| ZA-YJV ZB-YJV ZC-YJV | Copper conductor, XLPE insulation flame-retardant Power Cable |

1 or 3 |

25~800mm2 |

| WDZA-YJY WDZB-YJY WDZC-YJY | Copper conductor, XLPE insulation Low Smoke Halogen Free or Zero Halogen (LSHF or LSZH) flame-retardant Power Cable |

1 or 3 |

25~800mm2 |

2. Operating Characteristics

Rated voltage U0/U(Um): 6.35/11(12)kV

xlpe cable is the rated power frequency voltage between conductor and earth or metallic screen for which the cable is designed; U is the rated power frequency voltage between conductors for which the cable is designed;

Um is the maximum value of the "highest system voltage" for which the equipment may be used.

Max. permissible continuous operating temperature of conductor: 90 °C

Max. temperature of conductor during short-circuit (5s max. duration) shall not exceed: 250 °C The ambient temperature under installation should not be lower than: 0 °C.

The bending radius of cable is recommended as following:

For single core cable: not less than 20 times of the diameter of cable

For three core cable: not less than 15 times of the diameter of cable

3. Application

The cable is used for fixed installations such as electric power distribution networks or industrial installations, which is laid indoors, outdoors, in tunnel or in cable trench, unable to bear external mechanical force.

Single core cable in magnetic duct is not permissible.

4. Manufacturing Standards

IEC 60502-2 and Chinese National Standard GB/T 12706-2008

We can produce above cables according to popular international standards such as ASTM,BS,DIN,NF &AS/NZ also.

5. Main technical data

5.1 Main technical data of 6.35/11KV, Single core, Copper conductor, XLPE insulated, and PVC or PE sheath cable

CABLE CONSTRUCTION: 6.35/11KV CU/XLPE/PVC or PE

| Size |

Nominal thickness of XLPE insulation(mm) |

Approx. thickness of copper tape screen (mm) |

Nominal thickness of PVC or PE(mm) |

Approx. overall diameter of finished cable(mm) |

Max. conductor D.C resistance @ 200C (Ω/km) |

| 1x25mm2 | 3.4 | 0.12 | 1.8 | 20.3 | 0.727 |

| 1x35mm2 | 3.4 | 0.12 | 1.8 | 21.3 | 0.524 |

| 1x50mm2 | 3.4 | 0.12 | 1.8 | 22.4 | 0.387 |

| 1x70mm2 | 3.4 | 0.12 | 1.8 | 24.1 | 0.268 |

| 1x95mm2 | 3.4 | 0.12 | 1.8 | 25.7 | 0.193 |

| 1x120mm2 | 3.4 | 0.12 | 1.8 | 27.1 | 0.153 |

| 1x150mm2 | 3.4 | 0.12 | 1.8 | 28.7 | 0.124 |

| 1x185mm2 | 3.4 | 0.12 | 1.9 | 30.5 | 0.0991 |

| 1x240mm2 | 3.4 | 0.12 | 2.0 | 33.1 | 0.0754 |

| 1x300mm2 | 3.4 | 0.12 | 2.0 | 35.1 | 0.0601 |

| 1x400mm2 | 3.4 | 0.12 | 2.1 | 38.5 | 0.0470 |

| 1x500mm2 | 3.4 | 0.12 | 2.2 | 42.2 | 0.0366 |

| 1x630mm2 | 3.4 | 0.12 | 2.3 | 46.3 | 0.0283 |

| 1x800mm2 | 3.4 | 0.12 | 2.5 | 50.4 | 0.0221 |

5.2 Main technical data of 6.35/11KV Single core, Copper conductor, XLPE insulated, copper wire screened and

PVC or PE sheath cable

CABLE CONSTRUCTION: 6.35/11KV CU/XLPE/CWS/PVC or PE,

| Size |

Nominal thickness of XLPE insulation(mm) |

Approx. thickness of copper tape screen (mm) |

Nominal diameter of copper wire(mm) |

Nominal thickness of PVC or PE(mm) |

Approx. overall diameter of finished cable(mm) |

Max. conductor D.C resistance @ 200C (Ω/km) |

| 1x25mm2 | 3.4 | 0.12 | 0.9 | 1.8 | 21.9 | 0.727 |

| 1x35mm2 | 3.4 | 0.12 | 0.9 | 1.8 | 22.9 | 0.524 |

| 1x50mm2 | 3.4 | 0.12 | 0.9 | 1.8 | 24.0 | 0.387 |

| 1x70mm2 | 3.4 | 0.12 | 0.9 | 1.8 | 25.7 | 0.268 |

| 1x95mm2 | 3.4 | 0.12 | 0.9 | 1.8 | 27.3 | 0.193 |

| 1x120mm2 | 3.4 | 0.12 | 0.9 | 1.8 | 28.7 | 0.153 |

| 1x150mm2 | 3.4 | 0.12 | 0.9 | 1.8 | 30.3 | 0.124 |

| 1x185mm2 | 3.4 | 0.12 | 0.9 | 1.9 | 32.1 | 0.0991 |

| 1x240mm2 | 3.4 | 0.12 | 0.9 | 2.0 | 34.7 | 0.0754 |

| 1x300mm2 | 3.4 | 0.12 | 0.9 | 2.1 | 36.9 | 0.0601 |

| 1x400mm2 | 3.4 | 0.12 | 0.9 | 2.2 | 40.3 | 0.0470 |

| 1x500mm2 | 3.4 | 0.12 | 0.9 | 2.3 | 44.2 | 0.0366 |

| 1x630mm2 | 3.4 | 0.12 | 0.9 | 2.4 | 48.0 | 0.0283 |

| 1x800mm2 | 3.4 | 0.12 | 0.9 | 2.5 | 52.0 | 0.0221 |

5.3 Main technical data of 6.35/11KV, three cores, Copper conductor, XLPE insulated, and PVC or PE sheath cable.

CABLE CONSTRUCTION: 6.35/11KV CU/XLPE/PVC or PE

| Size |

Nominal thickness of XLPE insulation(mm) |

Approx. thickness of copper tape screen (mm) |

Nominal thickness of PVC or PE(mm) |

Approx. overall diameter of finished cable(mm) |

Max. conductor D.C resistance @ 200C (Ω/km) |

| 3x25mm2 | 3.4 | 0.10 | 2.2 | 40.9 | 0.727 |

| 3x35mm2 | 3.4 | 0.10 | 2.3 | 43.3 | 0.524 |

| 3x50mm2 | 3.4 | 010 | 2.4 | 45.9 | 0.387 |

| 3x70mm2 | 3.4 | 0.10 | 2.5 | 49.8 | 0.268 |

| 3x95mm2 | 3.4 | 0.10 | 2.6 | 53.6 | 0.193 |

| 3x120mm2 | 3.4 | 0.10 | 2.7 | 56.8 | 0.153 |

| 3x150mm2 | 3.4 | 0.10 | 2.8 | 60.6 | 0.124 |

| 3x185mm2 | 3.4 | 0.10 | 2.9 | 64.3 | 0.0991 |

| 3x240mm2 | 3.4 | 0.10 | 3.1 | 69.9 | 0.0754 |

| 3x300mm2 | 3.4 | 0.10 | 3.3 | 74.6 | 0.0601 |

| 3x400mm2 | 3.4 | 0.10 | 3.5 | 82.2 | 0.0470 |

- Next: 795 ACSR Drake Conductor with Low Price Aluminum Overhead Bare Conductor

- Previous: 3 Core 240 Sq mm XLPE Power Cable Price Swa/Sta Armouring Cable

Contact us

Similar Or Related

-

0.6/1kv Swa Armoured Copper Conductor XLPE PVC Insulated Power Cable

-

Garden Light Waterproof 3 Phase Underground 16mm Aluminum PVC XLPE Power Cable

-

Overhead Transmission Line Electric Wire Swa Armoured Copper Conductor XLPE Insulated Cable

-

Cable Manufacturers 70mm2 Swa Steel Wire Armoured Copper XLPE Insulation Cable