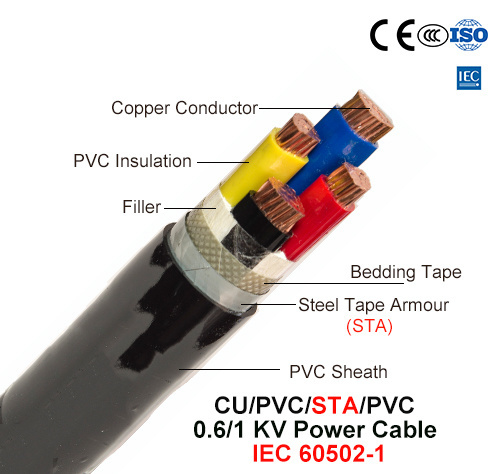

Cu/PVC/Sta/PVC, 0.6/1 Kv, Steel Tape Armour Power Cable (IEC 60502-1)

Product Description

CONSTRUCTION

Conductor: Plain annealed stranded circular (rm) or sector shaped (sm) copper conductor, as per Class 2 of IEC 60228.

Insulation: An extruded layer of Polyvinyl chloride (PVC) insulation, rated 70 º C at normal operation to IEC 60502-1.

Bedding: An extruded layer of Polyvinyl chloride (PVC).

Armouring: Double layer of galvanized steel tapes.

Outer sheath: An extruded layer of Polyvinyl chloride (PVC) sheathing compound type ST1 to IEC 60502-1.

APPLICATION

For outdoor installations in power stations, industrial plants and switchgears if mechanical protection is required or in applications where mechanical damages are expected to occur.

TECHNICAL DATA

– Nominal voltage Uo/U = 0.6/1 kV

– Power frequency test voltage 3.5 kV for 5 minutes

– Max. Admissible temperature of conductor at normal operation 70 º C

– Max. Admissible temperature of conductor at short circuit 160 º C for 5 seconds

| Cross-section | Max. Conductor Resistance | Current Rating | Overall Diameter | Cable Weight | |||

| DC at 20 | AC at 70 | Laid in Ground | Laid in Ducts | Laid in free air | |||

| mm2 | Ω/km | A | mm | kg/km | |||

| Two Cores | |||||||

| 6 | 3.0800 | 3.6900 | 50 | 40 | 50 | 16.9 | 460 |

| 10 | 1.8300 | 2.1900 | 65 | 55 | 66 | 18.7 | 585 |

| 16 | 1.1500 | 1.3900 | 85 | 65 | 88 | 20.7 | 760 |

| 25 | 0.7270 | 0.8700 | 110 | 85 | 116 | 24.1 | 1025 |

| 35 | 0.5240 | 0.6280 | 130 | 105 | 143 | 26.3 | 1325 |

| Three Cores | |||||||

| 4 | 4.6100 | 5.5400 | 35 | 30 | 31 | 16.4 | 440 |

| 6 | 3.0800 | 3.6900 | 45 | 36 | 39 | 17.5 | 525 |

| 10 | 1.8300 | 2.1900 | 60 | 48 | 53 | 19.7 | 725 |

| 16 | 1.1500 | 1.3900 | 75 | 60 | 72 | 21.8 | 950 |

| 25 | 0.7270 | 0.8700 | 100 | 80 | 94 | 25.5 | 1340 |

| 35 | 0.5240 | 0.6280 | 120 | 95 | 110 | 25.8 | 1560 |

| Four Cores | |||||||

| 4 | 4.6100 | 5.5400 | 35 | 30 | 31 | 17.6 | 520 |

| 6 | 3.0800 | 3.6900 | 45 | 36 | 39 | 18.8 | 630 |

| 10 | 1.8300 | 2.1900 | 60 | 48 | 53 | 21.3 | 885 |

| 16 | 1.1500 | 1.3900 | 75 | 60 | 72 | 23.7 | 1180 |

| 25 | 0.7270 | 0.8700 | 100 | 80 | 94 | 27.8 | 1680 |

| 35 | 0.5240 | 0.6280 | 120 | 95 | 110 | 27.9 | 1970 |

| 50 | 0.3870 | 0.4640 | 145 | 115 | 138 | 32.7 | 2640 |

| 70 | 0.2680 | 0.3220 | 175 | 145 | 171 | 37.5 | 3915 |

| 95 | 0.1930 | 0.2320 | 210 | 165 | 209 | 42.4 | 5140 |

| 120 | 0.1530 | 0.1850 | 240 | 195 | 242 | 46.2 | 6310 |

| 150 | 0.1240 | 0.1510 | 270 | 220 | 275 | 50.9 | 7615 |

| 185 | 0.0991 | 0.1210 | 300 | 245 | 314 | 56.1 | 9365 |

| 240 | 0.0754 | 0.0840 | 345 | 290 | 374 | 62.6 | 12790 |

| 300 | 0.0601 | 0.0770 | 390 | 320 | 440 | 68.7 | 14645 |

| 4+1 Cores | |||||||

| 35/16 | 0.5240 / 1.1500 | 0.6280 / 1.3900 | 120 | 95 | 110 | 26.8 | 1770 |

| 50/25 | 0.3870 / 0.7270 | 0.4640 / 0.8700 | 145 | 115 | 138 | 30.9 | 2365 |

| 70/35 | 0.2680 / 0.5240 | 0.3220 / 0.6280 | 175 | 145 | 171 | 34.6 | 3155 |

| 95/50 | 0.1930 / 0.3870 | 0.2320 / 0.4640 | 210 | 165 | 209 | 40.7 | 4625 |

| 120/70 | 0.1530 / 0.2680 | 0.1850 / 0.3220 | 240 | 195 | 242 | 44.5 | 5730 |

| 150/70 | 0.1240 / 0.2680 | 0.1510 / 0.3220 | 270 | 220 | 275 | 48.5 | 6740 |

| 185/95 | 0.0991 / 0.1930 | 0.1210 / 0.2320 | 300 | 245 | 314 | 53.2 | 8300 |

| 240/12 | 0.0754 / 0.1530 | 0.0840 / 0.1850 | 345 | 290 | 374 | 59.6 | 10550 |

| 300/15 | 0.0601 / 0.1240 | 0.0770 / 0.1510 | 390 | 320 | 440 | 65.4 | 12920 |

- Next: 1-Cyky, Power Cable, 0.6/1 Kv, Cu/PVC/PVC (IEC 60502-1)

- Previous: Ny2y, Power Cable, 0.6/1 Kv, Cu/PVC/HDPE (VDE 0276-603/HD 603)

Contact us

Similar Or Related

-

10X1.5mm2 Flame Retardant Copper Tape Screen Steel Tape Armored PVC Sheathed Control Cable 0.6/1kV

-

JZ-500 Flexible Copper Control Cable PVC Insulated 300/500V DIN VDE 0285-525

-

0.3/0.5kV 4X4mm2 Copper Wire Braiding PVC Insulation Low Voltage Control Power Cable

-

24X2.5mm2 XLPE Insulated Steel Tape Armoured Control/Instrumentation Cable IEC 60502-1

-

Cu/PVC/Sta/PVC, 0.6/1 Kv, Steel Tape Armour Power Cable (IEC 60502-1)