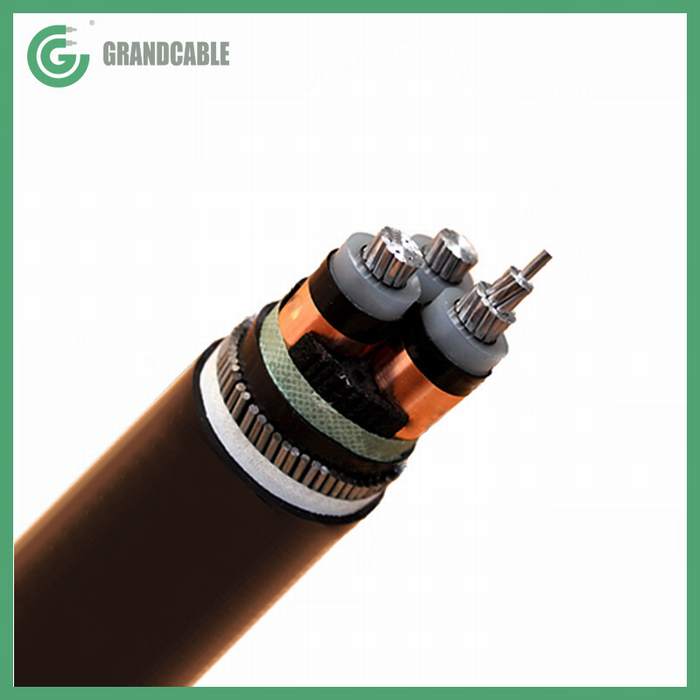

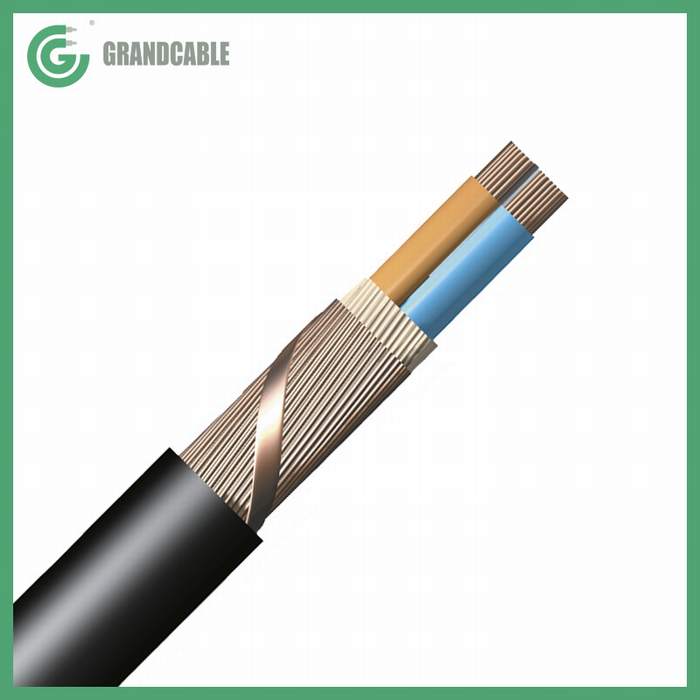

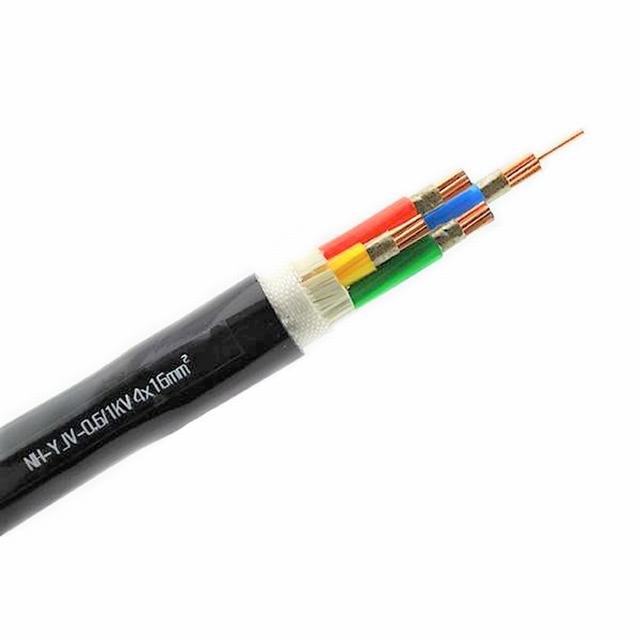

Copper Fire Resistance XLPE Insulation Flame Retardant Sheath Power Cable

Product Description

Flame retardant cable

The flame retardant cable is mainly featured in low liability of fire or that second combustion is only limited to a certain range, meets the IEC60332 combustion testing requirements, and is applicable to the places with flame retardant requirement.

Product Category

1. Ordinary flame retardant cable: In the event of fire, the cable may produce a large amount of corrosive gases and smoke after combustion, and can be used in general occasions with low flame retardant requirement. Its flammability has A, B,C, D four categories, and its cable models are added with ZRA- (or ZA-), ZRB- (or ZB-), ZRC- (or ZC-), and ZRD- (or ZD-)

before ordinary cable models, respectively.

2. Low-halogen flame-retardant cable: in addition to maintaining the general characteristics and electrical properties of the

flame-retardant cable, it also has the following characteristics:

a. low halogen acid gas emissions;

b. low corrosivity;

c. less smoke generated.

Its cable model is added with DDZ- (or DL-) before ordinary XLPE insulated cables model.

3. Low smoke zero halogen (LSZH) flame retardant cable: featured in:

a. no halogen acid gas release;

b. small fuming amount;

c. less corrosive gas generated;

d. good flame retardant property.

and has certain mechanical and physical and electrical properties to meet the operating requirements for the cable. It is widely used in nuclear power plants, subway stations, telephone switching and computer control centers, high-rise

buildings, hotels, radio and television stations, important military facilities, oil platforms, etc. Its cable models include WDZYJY,WDZ-YJY23, WDZ-YJY33, WDZ-YJY43, WDZ-YJE, WDZ-YJE23, WDZ-YJE33, WDZ-YJE43 or WL-YJE, WL-YJL23,WL-YJL33, and WL- YJL43, and can be matched with the flame retardant levels A, B, C, D, such as WDZA-.

4. Oxygen-barrier cable (also known as highly-flame retardant cable): a layer of non-melting, non-flammable, halogen-free,smoke-free fire-resistant plastic material is filled or wrapped between the cable insulated core and the cable sheath, i.e.insulating organic is used to isolate the cable from the outside oxygen gas, so that the cable is non-combustible or flameretardent.

Its cable model is added with GZR- before the ordinary cable model.

Main features

1. Ordinary flame retardant cable

For Class A and Class B fire tests, the fire time is 40 minutes, and for Class C and Class D fire tests, the fire time is 20 minutes, and the charring height does not exceed 2.5 m.

2. Low-halogen low-smoke flame retardant cable

Halogen acid gas emission <100 mg/g, smoke density (transmittance) > 30%, from the group burning test, it meets the requirements of Class C flame retardancy.

3. Low smoke zerohalogen (LSZH) flame retardant cable:

Halogen acid gas all-emission 0 mg/g, pH value ≥ 4.3, conductivity ≤ 10 us/mm, toxicity index ≤ 5. From the group burning test, it at least meets the requirements of Class C flame retardancy, smoke density (transmittance) ≥

60%.

4. Oxygen barrier cable (highly-flame retardant cable)

From the group burning test, it meets and exceeds the requirements of Class A flame retardancy, and the smoke density (transmittance) is equal to or close to national standard GB/T17651-2008 and international standard IEC61034 low smoke standard.

It is especially suitable for 6 KV-35 KV medium-voltage cable frame retardancy, has not only flame retardancy up to Class A, but also has certain refractory characteristics (i.e. can still keep 2.4 Uo insulation standard after burning for 20 min).

Notes: Users can select category and class of flame retardant cable according to laying places.

Fire-resistant cable

Fire-resistant cable can still ensure the normal operation of lines within certain time in case of combustion. It is different from the ordinary flame retardant cable in that in the event of a fire, it may continue electricity transmission. The use of this product will allow high-rise buildings, subways, power plants and other major occasions to have better fire safety and fire rescue capability.

Operating characteristics

1. Cable laying temperature: ≥0°C

2. The highest rated temperature values of PVC insulated cable conductor and XLPE insulated cable conductor are 70°C, and 90°C, respectively.

3. The highest rated temperature values of cable conductor in case of short circuit (the longest duration not more than 5s) does not exceed 160°C and 250°C for PVC insulation and XLPE insulation, respectively

4. Under rated voltage of the cable, the fire-resistant cable can maintain 90 min normal operation in is 750°C-800°C flame.

5. Bending radius: same as ordinary cable.

Description of Flame retardant and fire resistant cable:

| Product name | Bunched flame retardant power wire shielded cable | Code letter |

| Conductor | Stranded or tinned copper wire | – |

| Insulation | Cross-linked polyethylene (XLPE) | J |

| Filler and tape | Non-hygroscopic material | – |

| Inner sheath | Polyvinyl chloride (PVC) | V |

| Screen or Armor | Galvanized steel wire braided | 9 |

| Outer sheath | Polyvinyl chloride (PVC) | 2 |

| Flame retardant | Bunched flame retardant | S |

| Low smoke and halogen free | Low smoke, halogen free and low toxicity | A |

| Rated voltage | 0.6/1kV | |

| Operating temperature | -15ºC~+90ºC | |

| Certificate | ABS,BV,CCS,DNV,GL,KR,LR,NK,RINA,RS | |

| Test voltage | 3.5kV/5min | |

| Smoke density of completed cable | ≥60% | |

| Application | shipboard,offshore building, lighting and control system | |

| Number of cores*section | 3*1.5 | |

| Weight | 195kg/km | |

| Outer diameter | 11.3-13.3mm | |

| Model | LKMSM-HF(CJV92/SA) |

Parameter of of copper Fire Resistant XLPE insulation Flame Retardant sheath Power cable

| N0.of cores×Nominal cross sectional area(mm²) | Caculated diameter | Caculated weight | |

| Nom(mm) | Max(mm) | CJV92(kg/km) | |

| 2*1 | 10.5 | 12.3 | 152 |

| 2*1.5 | 11.1 | 13 | 172 |

| 2*2.5 | 11.9 | 14 | 208 |

| 2*4 | 13.3 | 15.6 | 265 |

| 2*6 | 14.3 | 16.8 | 323 |

| 2*10 | 16.8 | 19.3 | 468 |

| 2*16 | 19.2 | 22.1 | 644 |

| 2*25 | 22.6 | 25.4 | 926 |

| 2*35 | 25.4 | 28.6 | 1201 |

| 2*50 | 29 | 32.6 | 1579 |

| 2*70 | 32.4 | 36.5 | 2095 |

| 2*95 | 37.2 | 40.9 | 2831 |

| 2*120 | 42 | 46.2 | 3551 |

| 2*150 | 45.8 | 50.4 | 4253 |

| 2*185 | 50.4 | 55.4 | 5194 |

| 3*1 | 11 | 12.9 | 171 |

| 3*1.5 | 11.6 | 13.6 | 197 |

| 3*2.5 | 12.7 | 14.9 | 250 |

| 3*4 | 14 | 16.5 | 316 |

| 3*6 | 15 | 17.6 | 393 |

| 3*10 | 18.1 | 20.8 | 596 |

| 3*16 | 20.2 | 22.7 | 812 |

| 3*25 | 24.3 | 27.3 | 1210 |

| 3*35 | 27.3 | 30.7 | 1583 |

| 3*50 | 30.7 | 34.5 | 2055 |

| 3*70 | 35.3 | 38.8 | 2870 |

| 3*95 | 40.2 | 44.2 | 3834 |

| 3*120 | 44.5 | 49 | 4718 |

| 3*150 | 48.6 | 53.5 | 5683 |

| 3*185 | 53.6 | 59 | 6979 |

Selection of current ratings shipboard power cable

Permission continuous operating temp of conductor 90°C

Current ratings of XLPE and EP rubber insulated power cable (Ambient temp 45°C

|

Nominal cross area of conductor (mm2) |

Single core |

two cores |

three or four cores |

five cores |

six cores |

|

A |

A |

A |

A |

A |

|

|

1 |

0.85 |

0.7 |

0.58 |

0.52 |

|

|

1 |

18 |

15 |

12 |

10 |

9 |

|

1.5 |

23 |

20 |

16 |

13 |

12 |

|

2.5 |

30 |

26 |

21 |

17 |

16 |

|

4 |

41 |

34 |

28 |

23 |

– |

|

6 |

52 |

44 |

36 |

30 |

– |

|

10 |

72 |

61 |

50 |

– |

– |

|

16 |

96 |

82 |

67 |

– |

– |

|

25 |

127 |

108 |

89 |

– |

– |

|

35 |

157 |

133 |

110 |

– |

– |

|

50 |

196 |

167 |

137 |

– |

– |

|

70 |

242 |

206 |

169 |

– |

– |

|

95 |

293 |

249 |

205 |

– |

– |

|

120 |

339 |

288 |

237 |

– |

– |

|

150 |

389 |

331 |

272 |

– |

– |

|

185 |

444 |

377 |

311 |

– |

– |

|

240 |

522 |

444 |

365 |

– |

– |

|

300 |

601 |

511 |

421 |

– |

– |

- Next: H07V-K Cable with PVC Insulated Flexible Wire 450/750V

- Previous: Vrv Flexible Power Cable From Zhengzhou Jinyuan

Contact us

Similar Or Related

-

15kV 3 Core 4/0AWG Aluminum Conductor XLPE Insulated SWA Armored MV Power Cable

-

XLPE Insulated Aerial Service Drop Cable Conductor #3AWG Duplex ICEA S-66-524 NEMA WC7

-

3Cx185mm2 XLPE Insulated Copper Tape Screened Galvanized Steel Wire Armored Power Cable 33kV

-

0.6/1kV 4Cx500mm2 Copper Conductor PVC Insulated SWA Armored LV Power Cable IEC 60502-1

-

Low Voltage Single Core Power Cable 1X300 mm2 N2XCH CU/XLPE/CWS/LSF 0.6/1kV

-

Copper Fire Resistance XLPE Insulation Flame Retardant Sheath Power Cable