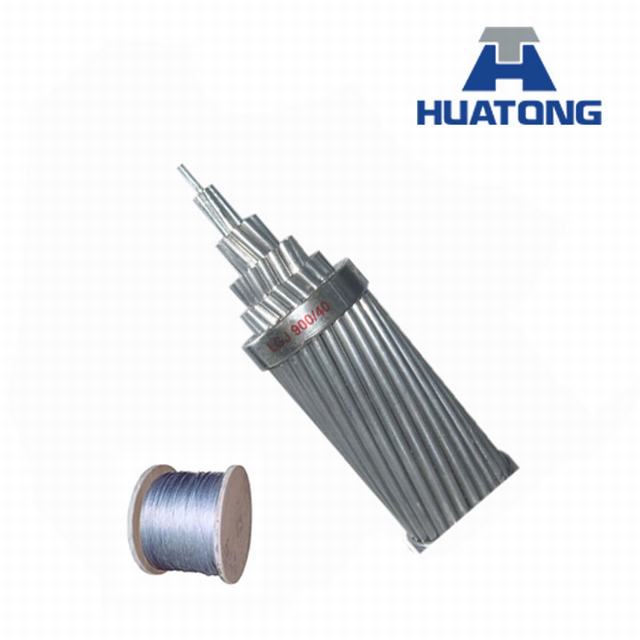

BS Standard ACSR Zebra with Best Price and Top Quality

Product Description

(1). What are Aluminium Conductors used for?

Aluminium Conductors are predominantly used in Overhead Line applications and for primary and secondary power distribution.

The higher strength ACSR conductors are used for river crossings, overhead earth wires, and installations involving extra long spans. The advantage of ACSR is that it has high tensile strength and is lightweight, which means over longer spans it needs less supports. ACSR is available with varying percentages of steel core to achieve different strengths. One of the advantages of this conductor in particular is that the desired strength can be achieved without a loss of ampacity.

AAC is used mainly in urban areas where the spacing is short and the supports are closer together. The advantage of AAC conductors is that they have a high degree of corrosion resistance; for this reason they are used extensively in coastal areas. AAC Conductors were developed as a consequence of the galvanic corrosion that ACSR conductors are susceptible to.

AAAC is used as bare overhead conductor for power transmission and distribution lines on aerial circuits that require larger mechanical resistance than AAC. AAAC also has better sag characteristics and a better strength to weight ratio than AAC. AAAC Cables have lower weight per unit length and slightly lower resistance per unit length than ACSR.

(2). What is the difference between ACSR, AAC and AAAC Conductors?

The biggest difference between AAC, AAAC, and ACSR conductors are the materials they are constructed from. AAC is manufactured from electrolytically refined aluminium with a 99.7% minimum purity, AAAC is made from an Aluminium alloy, and ACSR contains a combination of Aluminium reinforced with Steel.

The second factor that differentiates the three cables is their resistance to corrosion, which is important for the longevity of the cable. ACSR has a poorer resistance to corrosion, as it contains steel, which is prone to rust. AAAC and AAC have a better corrosion resistance, due to the fact that they are largely or completely aluminium.

In an ACSR the galvanised steel core carries the mechanical load and the high purity aluminium carries the current. These utilise the lower thermal expansion coefficient of steel compared to aluminium, which the aluminium based conductors AAC and AAAC are unable to do.

2. Type & Designation

| Type | Description | No. of Wire | Section Area (mm2) |

| AAC | All Aluminum Conductor | 7~127 | 16~1500 |

| AAAC | All Aluminum Alloy Conductor | 7~91 | 17~1300 |

| ACSR | Aluminum Conductors Steel Reinforced | 7~103 | 16~1250 |

| AACSR | Aluminum Alloy Conductors Steel Reinforced | 7~103 | 16~1250 |

| ACAR/AW | Aluminum Conductors Aluminum Alloy Reinforced | 7~103 | 16~1250 |

| ACSW/S | Aluminum Conductor Aluminum Clad Steel Wire/Strand | 7~103 | 16~1250 |

| GSW | Galvanized Steel Wire | 3/2.64~37/4.55 | 16.41~765.99 |

3 .Applications

Conductor(AAC,AAAC and ACSR) have been widely used in power transmission lines with various voltage levels,because they have such good characteristics as simple structure,convenient installation and maintenance,low cost large transmission capacity.And they are also suitable for laying across rivers valleys and the places where special geographical features exist.

2.Service Performance

(1).The permissible long-time operating temperature for aerial conductor is 70oC.

(2).Under the circumstance that rare climate is occuring and ice coverage rate low in heavy ice area,the biggest stress of cable at the lowest point of the sag should not exceed 60% of the short-time destructive power.

(3).When connecting conductors,the conductor beside the connecting tube cant be prominent.Otherwise,the force on the operating conductors will be unbalanced.After connectors are install,the connecting tube should be painted by moisture-proof varnish in order to protect it from corrosion.

(4).Under installaion,the arc downing stress of all the conductors should be the same.With in the permissible distance of crossing buildings or dropping to the ground,the stress can be 10-15% higher than regular stress.

4.Technical details

AAC Technical Characteristics Based on Standard DIN 48201 / DIN EN50182

| Code number | Area | Number of wires | Wire diameter | Conductor diameter | Linear mass | Rated strength | D.C. resistance at 20oC |

| mm2 | No. | mm | mm | kg/km | kN | Ω/km | |

| 16 | 15.9 | 7 | 1.7 | 5.1 | 43.4 | 3.02 | 1.7986 |

| 25 | 24.2 | 7 | 2.1 | 6.3 | 66.3 | 4.36 | 1.1787 |

| 35 | 34.4 | 7 | 2.5 | 7.5 | 93.9 | 6.01 | 0.8317 |

| 50 | 49.5 | 7 | 3 | 9 | 135.2 | 8.41 | 0.5776 |

| 50 | 48.3 | 19 | 1.8 | 9 | 132.9 | 8.94 | 0.5944 |

| 70 | 65.8 | 19 | 2.1 | 10.5 | 180.9 | 11.85 | 0.4367 |

| 95 | 93.3 | 19 | 2.5 | 12.5 | 256.3 | 16.32 | 0.3081 |

| 120 | 117 | 19 | 2.8 | 14 | 321.5 | 19.89 | 0.2456 |

| 150 | 147.1 | 37 | 2.25 | 15.8 | 405.7 | 26.48 | 0.196 |

| 185 | 181.6 | 37 | 2.5 | 17.5 | 500.9 | 31.78 | 0.1588 |

| 240 | 242.5 | 61 | 2.25 | 20.3 | 671.1 | 43.66 | 0.1193 |

| 300 | 299.4 | 61 | 2.5 | 22.5 | 828.5 | 52.4 | 0.0966 |

ACSR Technical Characteristics Based on Standard BS 215-2

| Code name | Nominal aluminium area | Stranding and wire diameter | Sectional area of aluminium | Total sectional area | Approx. overall diameter | Approx. mass | Calculated D.C. resistance at 20oC | Calculated breaking load | |

| Al | Steel | ||||||||

| mm2 | No./mm | mm2 | mm2 | mm | kg/km | Ω/km | kN | ||

| RABBIT | 50 | 6/3.35 | 1/3.35 | 52.88 | 61.7 | 10.05 | 214 | 0.5426 | 18.35 |

| DOG | 100 | 6/4.72 | 7/1.57 | 105 | 118.5 | 14.15 | 394 | 0.2733 | 32.7 |

| WOLF | 150 | 30/2.59 | 7/2.59 | 158.1 | 194.9 | 18.13 | 726 | 0.1828 | 69.2 |

| DINGO | 150 | 18/3.35 | 1/3.35 | 158.7 | 167.5 | 16.75 | 506 | 0.1815 | 35.7 |

| LYNX | 175 | 30/2.79 | 7/2.79 | 183.4 | 226.2 | 19.53 | 842 | 0.1576 | 79.8 |

| ZEBRA | 400 | 54/3.18 | 7/3.18 | 428.9 | 484.5 | 28.62 | 1621 | 0.0674 | 131.9 |

5. About Us

6. Why Choose Us– Jinyuan Cable Inc

(1)More than 30 years experience.

(2)100,000m² factory,200 staffs,annual output 100,000 metic tons.

(3)Sound Quality Control

1) Material inspection;

2) manufacturing inspection;

3) Finished products inspection;

4) Inspection before delivery.

5) Third party inspection.

6) Inspection of storage at port of departure.

(4)ISO Certificated.

(5)Plenty of material and lobor gurantee the delivery prompt and price competitive.

(6)24/7 service.

- Next: Ho3VV-F Flexible Copper Wire Three Core 300/300V Electric Wire BS 6500

- Previous: Ho5rr-F Flexible Rubber Cable BS Standard

Contact us

Similar Or Related

- No related articles