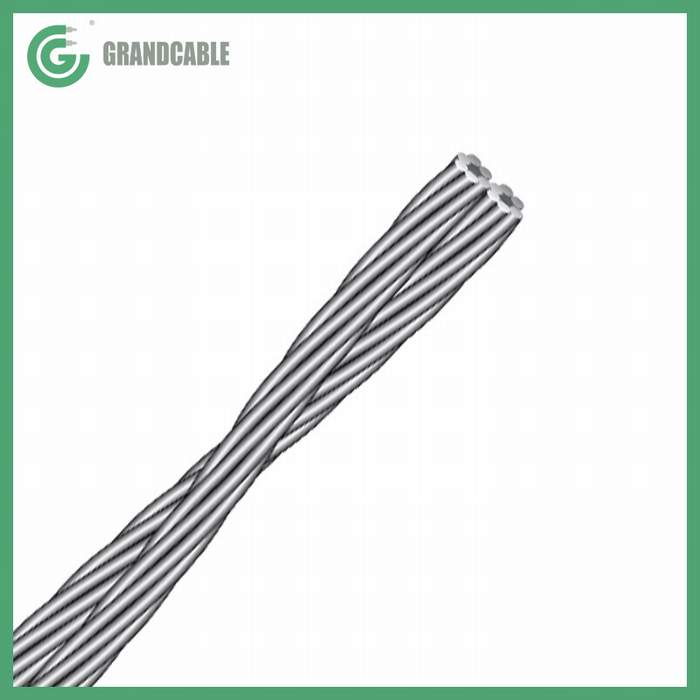

ASTM Standard Alumoweld Cable (ACS) /Aluminum-Cald Steel Wire

Product Description

CONSTRUCTION

Stranded aluminum clad steel wires are concentrically stranded and wrapped helically around a central wire. The additional corrosion protection is available through the application of grease to the cores or infusion of the complete cable with grease.

Aluminum clad steel products are manufactured with a high-purity aluminum powder compacted around a high-strength steel rod. With subsequent applications of heat and pressure, a bimetallic rod with a dense, inseparably welded cladding is obtained.

After cladding, the bimetallic rod is drawn to finished wire sizes without changing the proportions of aluminum and steel. The finished wire maintains its continuous ductile weld and dense uniform aluminum cladding which provides superior corrosion resistance and excellent electrical conductivity.

1. FEATURES

Corrosion resistant in industrial, semi-industrial and marine environments

Superior to aluminized steel

Lightweight

Same tensile strength as extra high strength steel but weighs 15 percent less

Excellent conductivity-much more conductive than galvanized steel and aluminum

Wider variety of properties and size of steel wire, thickness of aluminum cladding, and quality of aluminum (cross sectional area ratio of the aluminum in AS wire covers approximately 13% to 85% while that designated in ASTM B415-92 is fixed at 25%)

Wider range of combinations of tensile strength and conductivity

Sufficiently strong bonding strength at the boundary between aluminum layer and steel core

Lighter in weight than galvanized and aluminized steel wire

Excellent thermal stability for continuous operation in high temperature

2. Standard

ASTM B416, DIN48201, GB/T 1179-2008 and ect.

3. Specification

Aluminum Clad Steel Wire/Alumoweld ASTM B416

| Code Number | Area | No. of wires | Diameters | Weight | Rated Strength | DC Resistance | |

| mm2 | wire | conductor | kg/km | kN | ohm/km | ||

| 3 No 5 Awg. | 50,32 | 3 | 4,62 | 9,96 | 334,1 | 54,42 | 1.699 |

| 3 No 6 Awg. | 39 ,00 | 3 | 4,11 | 8,87 | 265,0 | 45,74 | 2.142 |

| 3 No 7 Awg. | 31,65 | 3 | 3,67 | 7,90 | 210,1 | 38,36 | 2.701 |

| 3 No 8 Awg. | 25,10 | 3 | 3,26 | 7,03 | 166,7 | 32,06 | 3.406 |

| 3 No 9 Awg. | 19,90 | 3 | 2,91 | 6,26 | 132,2 | 25,43 | 4.294 |

| 3 No 10 Awg. | 15,78 | 3 | 2,59 | 5,58 | 104,8 | 20,16 | 5.415 |

| 7 No 5 Awg. | 117,40 | 7 | 4,62 | 13,90 | 781,1 | 120,27 | 0,7426 |

| 7 No 6 Awg. | 93,10 | 7 | 4,11 | 12,40 | 619,5 | 101,14 | 0,9198 |

| 7 No 7 Awg. | 73,87 | 7 | 3,67 | 11,00 | 491,1 | 84,81 | 1.16 |

| 7 No 8 Awg. | 58,56 | 7 | 3,26 | 9,78 | 389,6 | 70,88 | 1.463 |

| 7 No 9 Awg. | 46,44 | 7 | 2,91 | 8,71 | 308,9 | 56,20 | 1.844 |

| 7 No 10 Awg. | 36,83 | 7 | 2,59 | 7,76 | 245,1 | 44,58 | 2.325 |

| 7 No 11 Awg. | 29,21 | 7 | 2,30 | 6,91 | 194,4 | 35,35 | 2.932 |

| 7 No 12 Awg. | 23,16 | 7 | 2,05 | 6,16 | 154,2 | 28,03 | 3.697 |

| 19 No 5 Awg. | 318,70 | 19 | 4,62 | 23,10 | 2129,0 | 326,39 | 0,2698 |

| 19 No 6 Awg. | 252,70 | 19 | 4,11 | 20,60 | 1688,0 | 274,55 | 0,3402 |

| 19 No 7 Awg. | 200,40 | 19 | 3,67 | 18,30 | 1339,0 | 230,18 | 0,4290 |

| 19 No 8 Awg. | 158,90 | 19 | 3,26 | 16,30 | 1062,0 | 192,41 | 0,5409 |

| 19 No 9 Awg. | 126,10 | 19 | 2,91 | 14,50 | 842,0 | 152,58 | 0,6821 |

| 19 No 10 Awg. | 99,96 | 19 | 2,59 | 12,90 | 667,7 | 121,00 | 0,8601 |

| 37 No 5 Awg. | 620,60 | 37 | 4,62 | 32,30 | 4170,0 | 635,43 | 0,1394 |

| 37 No 6 Awg. | 492,20 | 37 | 4,11 | 28,80 | 3307,0 | 534,85 | 0,1757 |

| 37 No 7 Awg. | 390,30 | 37 | 3,67 | 25,70 | 2623,0 | 448,09 | 0,2216 |

| 37 No 8 Awg. | 309,50 | 37 | 3,26 | 22,90 | 2080,0 | 374,67 | 0,2794 |

| 37 No 9 Awg. | 245,50 | 37 | 2,91 | 20,30 | 1649,0 | 279,11 | 0,3523 |

| 37 No 10 Awg. | 194,70 | 37 | 2,59 | 17,90 | 1308,0 | 235,61 | 0,4443 |

Aluminum Clad Steel Wire/Alumoweld DIN 48201

| Code Number | Area | No. of wires | Diameters(mm) | Weight | Rated Strength | DC Resistance | |

| mm2 | mm2 | wire | conductor | kg/km | kN | ohm/km | |

| 25 | 24.25 | 7 | 2.1 | 6.3 | 162 | 31.56 | 3.546 |

| 35 | 34.36 | 7 | 2.5 | 7.5 | 229 | 44.72 | 2.499 |

| 50 | 49.48 | 7 | 3 | 9 | 330 | 64.4 | 1.736 |

| 70 | 65.81 | 19 | 2.1 | 10.5 | 441 | 85.65 | 1.313 |

| 95 | 93.27 | 19 | 2.5 | 12.5 | 626 | 121.39 | 0.925 |

| 120 | 116.99 | 19 | 2.8 | 14 | 785 | 152.26 | 0.737 |

| 150 | 147.11 | 37 | 2.25 | 15.7 | 990 | 191.46 | 0.587 |

| 185 | 181.62 | 37 | 2.5 | 17.5 | 1221 | 236.38 | 0.476 |

| 240 | 242.54 | 61 | 2.25 | 20.2 | 1635 | 299.05 | 0.357 |

| 300 | 299.43 | 61 | 2.5 | 22.5 | 2017 | 369.2 | 0.289 |

FACTORY VIEW

QC&QA

CERTIFICATE

LOADING PICTURES

CUSTOMER VISIT