Anti-Corrosion Type ACSR Conductor with IEC Certificate

Product Description

ACSR conductor

ASTM B232 standard Merlin acsr conductor

ACSR,AAC,AAAC,ASCSR&ACAR conductor widely used in power transmission lines with various voltage levels. since they have such good characteristics as simple structure, convenient installation and maintenance, low cost for the line, large transmission capacity and are also suitable for laying across rivers and valleys where special geographical teatures exist.

1. Specification:

(1) all aluminium conductor (AAC)

(2) all aluminimum alloy conductor(AAAC)

(3) aluminum conductor steel reinforced (ACSR)

(4) anti-corrosion type ACSR

(5) aluminimum conductor aluminimum clad steel reinforced(ACSR/AW)

(6)rear earth aluminimum conductor steel reinforced(ACSR/RE)

(7)aluminimum conductor aluminimum alloy reinforced(ACAR)

| ACSR British Sizes BS215-1 | ||||||||||

| Code name | Nominal Al. Area | Stranding and Wire diameter | Sectional area of Al. | Total sectional area | Overall diameter | Calculated Breaking Load | Calculate D.C Resistance at 20 | Final modulus of elasticity | ||

| mm2 | Al. | Steel | mm2 | mm2 | mm | daN | /km | hbar | ||

| Mole | 10 | 6/1.50 | 1/1.50 | 10.52 | 4.50 | 43 | 414 | 2.706 | 7900 | |

| Squirrel | 20 | 6/2.11 | 1/2.11 | 20.94 | 6.33 | 85 | 788 | 1.368 | 7900 | |

| Gopher | 25 | 6/2.36 | 1/2.36 | 26.24 | 7.08 | 106 | 961 | 1.093 | 7900 | |

| Weasel | 30 | 6/2.59 | 1/2.59 | 31.61 | 7.77 | 128 | 1146 | 0.9077 | 7900 | |

| Fox | 35 | 6/2.79 | 1/2.79 | 36.66 | 8.37 | 149 | 1320 | 0.7822 | 7900 | |

| Ferret | 40 | 6/3.00 | 1/3.00 | 42.41 | 9.00 | 172 | 1520 | 0.6766 | 7900 | |

| Rabbit | 50 | 6/3.35 | 1/3.35 | 52.88 | 10.05 | 214 | 1835 | 0.5426 | 7900 | |

| Mink | 60 | 6/3.66 | 1/3.66 | 63.18 | 10.98 | 255 | 2180 | 0.4545 | 7900 | |

| Shunk | 60 | 12/2.59 | 7/2.59 | 63.27 | 12.95 | 465 | 5300 | 0.4567 | 10500 | |

| Beaver | 70 | 6/3.99 | 1/3.99 | 74.82 | 11.97 | 302 | 2570 | 0.3825 | 7900 | |

| Horse | 70 | 12/2.79 | 7/2.79 | 73.37 | 13.95 | 538 | 6120 | 0.3936 | 10500 | |

| Racoon | 75 | 6/4.10 | 1/4.10 | 79.20 | 12.30 | 320 | 2720 | 0.3622 | 7900 | |

2. Elative manufacturing standards: IEC83, IEC1089, 31, B232, BS215, DIN48204

(1). Standard: IEC61089, BS215 part2, ASTM B232, DIN48204, BS EN50182

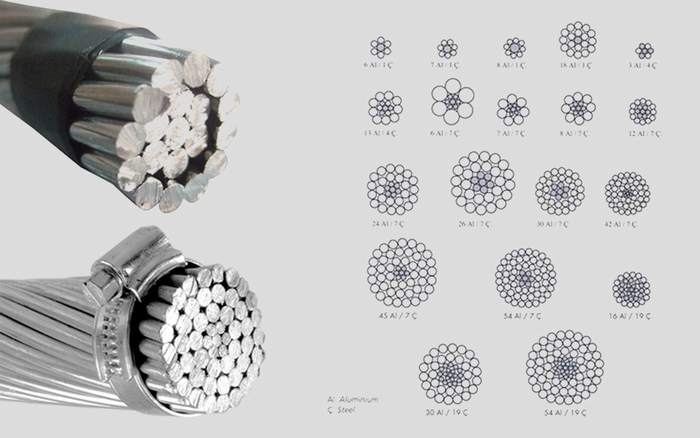

(2). Specification: ACSR is composed by bare concentric-lay-stranded galvanized steel wire(s) with aluminum wires surrounded by one or more layers of helically. Greased ACSR can also be supplied.

(3). Application: ACSR is widely used in overhead electric power transmission and distribution lines with various voltage levels

We can supply this conductor according to different recognized standards, such as IEC61089, BS215, BS EN 50182: 2001, STM B231, CSA C49, DIN480201, JIS C3109, customer special specification also can be satisfied.

ACSR conductor

Standard: ASTM B232 ,IEC61089, BS215 part2, DIN48204, BS EN50182, GB/T 1179-2008

Brief Description:

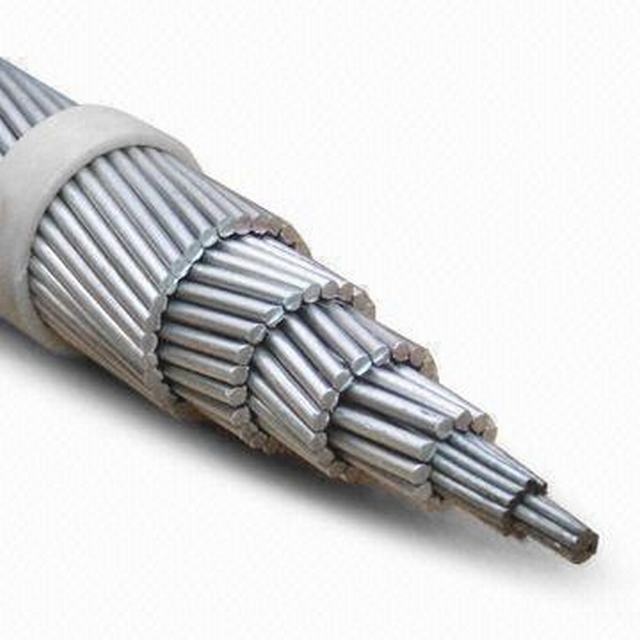

ACSR conductor consists of a solid or stranded steel core surrounded by strands of aluminium (E.C. GRADE).

ACSR Conductor may be manufactured for having a wide range of tensile strength as per requirement.

The principal advantage of these conductors are high tensile strength and light weight with longer spans as well as

with lesser supports. Due to the greater diameter of ACS Conductor a much higher corona limit can be obtained causing

big advantages on high as well as extra high voltage overhead lines.

Applications:

Used as bare overhead transmission cable and as primary and secondary distribution cable.

ACSR Conductor offers optimal strength for line design. Variable steel core stranding enables

desired strength to be achieved without sacrificing ampacity. ACSR Conductor are used extensively

for overhead ground wires, river crossings etc. These ACSR Conductor are available with us in various types for

meeting the exact requirements of the clients.

Package:In coils, wooden drums, steel drums or steel-wooden drums.

We could producing according to the customers’ requirements.Welcome your request for any quotations.

| Aluminum Conductors Steel Reinforced ASTM B 232 | ||||||||||||

| Code name | Area | Stranding and wire diameter | Approx. overall diameter | Weight | Nominal breaking load | Nominal DC resistance at 20 deg. | ||||||

| Nominal | Alum. | Steel | Total | Alum. | Steel | Alum. | Steel | Total | ||||

| AWG or MCM | mm2 | mm2 | mm2 | mm | mm | mm | kg/km | kg/km | kg/km | kN | Ohm/km | |

| TURKEY | 6 | 13.29 | 2.19 | 15.48 | 6/1.68 | 1/1.68 | 5.04 | 37 | 17 | 54 | 5.24 | 2.1586 |

| SWAN | 4 | 21.16 | 3.55 | 24.71 | 6/2.12 | 1/2.12 | 6.36 | 58 | 27 | 85 | 8.32 | 1.3557 |

| SWANATE | 4 | 21.16 | 5.35 | 26.51 | 7/1.96 | 1/2.61 | 6.53 | 58 | 42 | 100 | 10.53 | 1.3557 |

| SPARROW | 2 | 33.61 | 5.61 | 39.22 | 6/2.67 | 1/2.67 | 8.01 | 92 | 44 | 136 | 12.7 | 0.8535 |

| SPARATE | 2 | 33.61 | 8.52 | 42.13 | 7/2.47 | 1/3.30 | 8.24 | 92 | 67 | 159 | 16.11 | 0.8535 |

| RAVEN | 1/0 | 53.48 | 8.9 | 62.38 | 6/3.37 | 1/3.37 | 10.11 | 147 | 69 | 216 | 19.32 | 0.5364 |

| QUAIL | 2/0 | 67.42 | 11.23 | 78.65 | 6/3.78 | 1/3.78 | 11.34 | 185 | 88 | 273 | 23.62 | 0.4255 |

| PIGEON | 3/0 | 85.03 | 14.19 | 99.22 | 6/4.25 | 1/4.25 | 12.75 | 233 | 110 | 343 | 29.41 | 0.3373 |

| PENGUIN | 4/0 | 107.23 | 17.87 | 125.1 | 6/4.77 | 1/4.77 | 14.31 | 294 | 139 | 433 | 37.06 | 0.2675 |

| PARTRIDGE | 266.8 | 135.16 | 22 | 157.16 | 26/2.57 | 7/2.00 | 16.28 | 374 | 172 | 546 | 50.29 | 0.2143 |

| MERLIN | 336.4 | 170.45 | 9.48 | 179.93 | 18/3.47 | 1/3.47 | 17.35 | 470 | 74 | 544 | 38.23 | 0.1691 |

| LINNET | 336.4 | 170.45 | 27.81 | 198.26 | 26/2.89 | 7/2.25 | 18.31 | 472 | 217 | 689 | 62.71 | 0.1699 |

| ORIOLE | 336.4 | 170.45 | 39.81 | 210.26 | 30/2.69 | 7/2.69 | 18.83 | 473 | 311 | 784 | 77.27 | 0.1704 |

| IBIS | 397.5 | 201.42 | 32.77 | 234.19 | 26/3.14 | 7/2.44 | 19.88 | 558 | 256 | 814 | 72.11 | 0.1438 |

| LARK | 397.5 | 201.42 | 46.97 | 248.39 | 30/2.92 | 7/2.92 | 20.44 | 560 | 367 | 927 | 88.69 | 0.1442 |

| PELICAN | 477 | 241.68 | 13.42 | 255.10 | 18/4.14 | 1/4.14 | 20.70 | 666 | 105 | 771 | 52.16 | 0.1193 |

| FLICKER | 477 | 241.68 | 31.29 | 272.97 | 24/3.58 | 7/2.39 | 21.49 | 670 | 245 | 915 | 76.66 | 0.1199 |

| HAWK | 477 | 241.68 | 39.42 | 281.10 | 26/3.44 | 7/2.67 | 21.79 | 670 | 308 | 978 | 86.65 | 0.1199 |

| HEN | 477 | 241.68 | 56.39 | 298.07 | 30/3.20 | 7/3.20 | 22.40 | 671 | 441 | 1112 | 105.34 | 0.1201 |

| OSPREY | 556.5 | 282.00 | 15.68 | 297.68 | 18/4.47 | 1/4.47 | 22.35 | 777 | 122 | 899 | 60.88 | 0.1022 |

| PARAKEET | 556.5 | 282.00 | 36.58 | 318.58 | 24/3.87 | 7/2.58 | 23.22 | 781 | 286 | 1067 | 88.22 | 0.1027 |

| DOVE | 556.5 | 282.00 | 45.94 | 327.94 | 26/3.72 | 7/2.89 | 23.55 | 781 | 359 | 1140 | 101.03 | 0.1027 |

| EAGLE | 556.5 | 282.00 | 65.81 | 347.81 | 30/3.46 | 7/3.46 | 24.21 | 783 | 515 | 1298 | 122.92 | 0.103 |

| PEACOCK | 605 | 306.58 | 39.74 | 346.32 | 24/4.03 | 7/2.69 | 24.20 | 849 | 311 | 1160 | 95.88 | 0.0945 |

| SQUAB | 605 | 306.58 | 49.94 | 356.52 | 26/3.87 | 7/3.01 | 24.51 | 850 | 390 | 1240 | 108.14 | 0.0945 |

| TEAL | 605 | 306.58 | 69.87 | 376.45 | 30/3.61 | 19/2.16 | 25.24 | 851 | 548 | 1399 | 133.59 | 0.0947 |

| GROSBEAK | 636 | 322.26 | 52.45 | 374.71 | 26/3.97 | 7/3.09 | 25.15 | 893 | 409 | 1302 | 111.8 | 0.08989 |

| STARLING | 715.5 | 362.58 | 59.03 | 421.61 | 26/4.21 | 7/3.28 | 26.68 | 1005 | 461 | 1466 | 125.91 | 0.07989 |

| TERN | 795 | 402.84 | 27.87 | 430.71 | 45/3.38 | 7/2.25 | 27.03 | 1116 | 217 | 1333 | 97.37 | 0.07191 |

| CONDOR | 795 | 402.84 | 52.19 | 455.03 | 54/3.08 | 7/3.08 | 27.72 | 1116 | 408 | 1524 | 124.45 | 0.07191 |

| CUCKOO | 795 | 402.84 | 52.19 | 455.03 | 24/4.62 | 7/3.08 | 27.74 | 1116 | 408 | 1524 | 123.94 | 0.07191 |

| DRAKE | 795 | 402.84 | 65.61 | 468.35 | 26/4.44 | 7/3.45 | 28.11 | 1116 | 512 | 1628 | 139.92 | 0.07191 |

| MALLARD | 795 | 402.84 | 91.87 | 494.71 | 30/4.14 | 19/2.48 | 28.96 | 1119 | 719 | 1838 | 171.18 | 0.07208 |

| RAIL | 954 | 483.42 | 33.42 | 516.84 | 45/3.70 | 7/2.47 | 29.61 | 1339 | 262 | 1601 | 115.63 | 0.05992 |

| CURLEW | 1033.5 | 523.68 | 67.87 | 591.55 | 54/3.52 | 7/3.52 | 31.68 | 1451 | 530 | 1981 | 161.8 | 0.05531 |

| BLUEJAY | 1113 | 563.93 | 39.03 | 602.96 | 45/4.00 | 7/2.66 | 31.98 | 1563 | 305 | 1868 | 132.63 | 0.05136 |

| FINCH | 1113 | 563.93 | 71.55 | 635.48 | 54/3.65 | 19/2.19 | 32.85 | 1570 | 560 | 2150 | 174.41 | 0.05161 |

| GRACKLE | 1192.5 | 604.26 | 76.58 | 680.84 | 54/3.77 | 19/2.27 | 33.97 | 1682 | 600 | 2282 | 186.38 | 0.04817 |

| BITTERN | 1272 | 644.51 | 44.52 | 689.03 | 45/4.27 | 7/2.85 | 34.17 | 1785 | 349 | 2134 | 151.48 | 0.04494 |

| DIPPER | 1351.5 | 684.84 | 47.10 | 731.94 | 45/4.40 | 7/2.92 | 35.16 | 1898 | 368 | 2266 | 160.7 | 0.0423 |

| MARTIN | 1351.5 | 684.84 | 86.71 | 771.55 | 54/4.02 | 19/2.41 | 36.17 | 1906 | 679 | 2585 | 206.05 | 0.0425 |

| LAPWING | 1590 | 805.68 | 55.48 | 861.16 | 45/4.77 | 7/3.18 | 38.16 | 2232 | 435 | 2667 | 187.02 | 0.03595 |

| FALCON | 1590 | 805.68 | 102.13 | 907.81 | 54/4.36 | 19/2.62 | 39.26 | 2243 | 799 | 3042 | 242.55 | 0.03613 |

| DOTTEREL | 176.9 | 89.48 | 52.19 | 141.67 | 12/3.08 | 7/3.08 | 15.42 | 248 | 409 | 657 | 78.5 | 0.3237 |

| DORKING | 190.8 | 96.71 | 56.39 | 153.10 | 12/3.20 | 7/3.20 | 16.03 | 268 | 441 | 709 | 84.8 | 0.2995 |

| COCHIN | 211.8 | 107.10 | 62.45 | 169.55 | 12/3.37 | 7/3.37 | 16.84 | 297 | 488 | 785 | 93.9 | 0.2705 |

| Aluminum Conductors Steel Reinforced BS 215 Part 2 | ||||||||||||

| Code name | Area | Stranding and wire diameter | Approx. overall diameter | Weight | Nominal breaking load | Nominal DC resistance at 20 deg. | ||||||

| Nominal | Alum. | Steel | Total | Alum. | Steel | Alum. | Steel | Total | ||||

| mm2 | mm2 | mm2 | mm2 | mm | mm | mm | kg/km | kg/km | kg/km | kN | Ohm/km | |

| MOLE | 10 | 10.62 | 1.77 | 12.39 | 6/1.50 | 1/1.50 | 4.50 | 29 | 14 | 43 | 4.14 | 2.076 |

| SQUIRREL | 20 | 20.94 | 3.49 | 24.43 | 6/2.11 | 1/2.11 | 6.33 | 58 | 27 | 85 | 7.88 | 1.368 |

| GOPHER | 25 | 26.25 | 4.37 | 30.62 | 6/2.36 | 1/2.36 | 7.08 | 72 | 34 | 106 | 9.61 | 1.093 |

| WEASEL | 30 | 31.61 | 5.27 | 36.88 | 6/2.59 | 1/2.59 | 7.77 | 87 | 41 | 128 | 11.45 | 0.9077 |

| FOX | 35 | 36.66 | 6.11 | 42.77 | 6/2.79 | 1/2.79 | 8.37 | 101 | 48 | 149 | 13.2 | 0.7822 |

| FERRET | 40 | 42.41 | 7.07 | 49.48 | 6/3.00 | 1/3.00 | 9 | 117 | 55 | 172 | 15.2 | 0.6766 |

| RABBIT | 50 | 52.88 | 8.82 | 61.7 | 6/3.35 | 1/3.35 | 10.05 | 145 | 69 | 214 | 18.35 | 0.5426 |

| HORSE | 70 | 73.37 | 42.8 | 116.17 | 12/2.79 | 7/2.79 | 13.95 | 203 | 335 | 538 | 61.2 | 0.3936 |

| RACOON | 75 | 79.2 | 13.2 | 92.4 | 6/4.10 | 1/4.10 | 12.3 | 217 | 103 | 320 | 27.2 | 0.3622 |

| OTTER | 80 | 83.88 | 13.98 | 97.86 | 6/4.22 | 1/4.22 | 12.66 | 230 | 109 | 339 | 28.80 | 0.3419 |

| CAT | 90 | 95.40 | 15.90 | 111.30 | 6/4.50 | 1/4.50 | 13.50 | 262 | 124 | 386 | 32.70 | 0.3007 |

| HARE | 100 | 105.00 | 17.50 | 122.50 | 6/4.72 | 1/4.72 | 14.16 | 288 | 137 | 425 | 36.00 | 0.2733 |

| DOG | 100 | 105 | 13.5 | 118.5 | 6/4.72 | 7/1.57 | 14.15 | 288 | 106 | 394 | 32.7 | 0.2733 |

| TIGER | 125 | 131.1 | 30.6 | 161.7 | 30/2.36 | 7/2.36 | 16.52 | 362 | 240 | 602 | 58 | 0.2202 |

| WOLF | 150 | 158 | 36.9 | 194.9 | 30/2.59 | 7/2.59 | 18.13 | 437 | 289 | 726 | 69.2 | 0.1828 |

| LYNX | 175 | 183.4 | 42.8 | 226.2 | 30/2.79 | 7/2.79 | 19.53 | 507 | 335 | 842 | 79.8 | 0.1576 |

| CARACAL | 175 | 184.2 | 10.3 | 194.5 | 18/3.61 | 1/3.61 | 18.05 | 507 | 80 | 587 | 41.1 | 0.1563 |

| PANTHER | 200 | 212 | 49.5 | 261.5 | 30/3.00 | 7/3.00 | 21 | 586 | 388 | 974 | 92.25 | 0.1363 |

| BEAR | 250 | 264 | 61.6 | 325.6 | 30/3.35 | 7/3.35 | 23.45 | 730 | 483 | 1213 | 111.1 | 0.1093 |

| BISON | 350 | 381.8 | 49.5 | 431.3 | 54/3.00 | 7/3.00 | 27 | 1056 | 388 | 1444 | 120.9 | 0.07573 |

| DEER | 400 | 429.3 | 100.2 | 529.5 | 30/4.27 | 7/4.27 | 29.89 | 1186 | 785 | 1971 | 178.5 | 0.06726 |

| ZEBRA | 400 | 428.9 | 55.6 | 484.5 | 54/3.18 | 7/3.18 | 28.62 | 1186 | 435 | 1621 | 131.9 | 0.0674 |

| MOOSE | 500 | 528.7 | 68.5 | 597.2 | 54/3.53 | 7/3.53 | 31.77 | 1462 | 537 | 1999 | 161.1 | 0.0547 |

ACSR Aluminum Conductor Steel-reinforced Power Cable

Features:

1) It is manufactured according to IEC 60889/BS 215/ASTM B 232

2) rated voltage is 500KV or lower

3) This series includes:

a) All aluminum conductors (AAC)

b) All aluminum alloy conductors (AAAC)

c) Aluminum conductor steel reinforced (ACSR)

d) Anti-corrosion ACSR

e) All steel conductors

4)Packing:Standard export wooden drums

(Aluminum Stranded Conductor ,Aluminum Conductor Steel-Reinforced,ACSR,bare wire,AAAC,Aluminum Stranded Conductor, bare wire,bare Aluminum wire, aluminum conductor )

Aluminium Conductor Steel Reinforced Henan ACSR factory

APPLICATIONS

ACSR conductor Used as bare overhead transmission conductor and as primary and secondary distribution conductor and messenger support.

ACSR offers optimal strength for line design. Variable steel core stranding enables desired strength to be achieved without sacrificing ampacity.

SPECIFICATIONS

ACSR bare conductor meets or exceeds the following ASTM specifications:

? B230 Aluminum 1350-H19 Wire for Electrical Purposes.

? B232 Concentric-Lay-Stranded Aluminum Conductors, Coated-Steel Reinforced (ACSR).

? B498 Zinc-Coated (Galvanized) Steel Core Wire for Use in Overhead Electrical Conductors.

? B500 Metallic Coated Stranded Steel Core for Use in Overhead Electrical Conductors.

CONSTRUCTION

? Aluminum 1350-H19 wires, concentrically stranded about a steel core. Standard core wire for ACSR is class A galvanized.

? Class A core stranding is also available in zinc-5% aluminum-mischmetal alloy coating.

? For aluminum-clad (AW) ACSR, please refer to the ACSR/AW catalog sheet

? Additional corrosion protection is available through the application of grease to the core or infusion of the complete cable with grease.

? ACSR conductor is also available in non-specular.