All aluminium Alloy Condutor (AAAC Overhead cable)

All aluminium Alloy Condutor (AAAC Overhead cable)

AAAC-BE2

Construction, Overhead, Industrial, Power Station

Acoording to Power system

DC Cable

Bare

No Sheath

Round Wire

Bare Aluminium Alloy Wire

ISO, CCC, CE

SGS

AAAC-Be2

Yifang

IEC 61089 & BS En 50182 & ASTM B 399

Yifang

Wooden Drum

16 mmsq to 1000 mmsq

China

8544609000

Product Description

1. Description

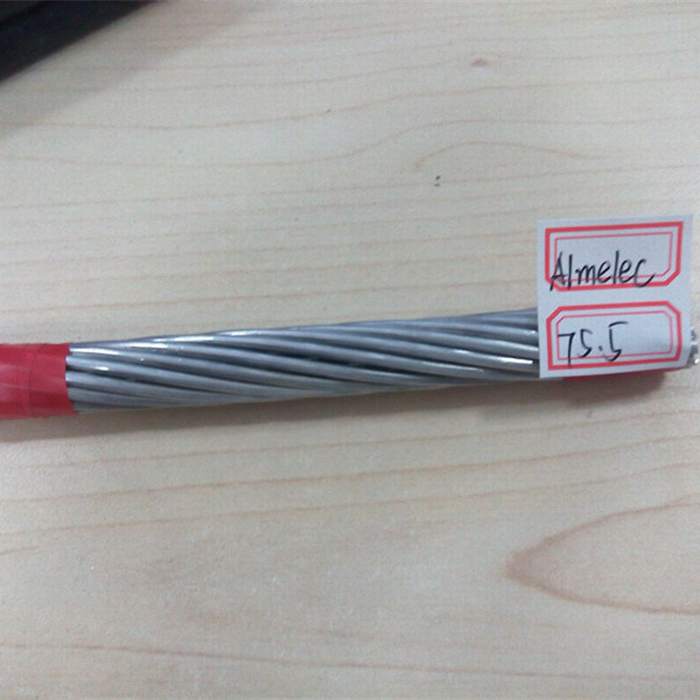

All Aluminium alloy (ALMELEC) conductors, stranded in successive layers, in opposite direction to form

the Aluminium stranded A.A.A.C. conductor

2. Excuative Standard

BS EN 50182 or ASTM B 399, IEC 61089

3. Application

AAAC are mainly used for overhead lines, in transmission and distribution electrical networks, having relatively

long spans. They are also used a messenger to support overhead electrical cables.

4. Specifications — Technical Information

IEC 60189

All Aluminium alloy (ALMELEC) conductors, stranded in successive layers, in opposite direction to form

the Aluminium stranded A.A.A.C. conductor

2. Excuative Standard

BS EN 50182 or ASTM B 399, IEC 61089

3. Application

AAAC are mainly used for overhead lines, in transmission and distribution electrical networks, having relatively

long spans. They are also used a messenger to support overhead electrical cables.

4. Specifications — Technical Information

IEC 60189

| Nominal Cross Sectional Area |

No. and Nominal Dia. of wires |

Max. DC. Resistance at20ºC |

Rated Strength |

Approx. Overall Dia. | Approx. Weight |

| mm² | No. X Φ (mm) | Ω/km | kN | mm | kg/km |

| 16 | 7 x 1.70 | 2.0701 | 4.69 | 5.10 | 43.4 |

| 25 | 7 x 2.10 | 1.3566 | 7.15 | 6.30 | 66.3 |

| 35 | 7 x 2.50 | 0.9572 | 10.14 | 7.50 | 93.9 |

| 50 | 7 x 3.00 19 x 1.80 |

0.6647 0.6841 |

14.60 14.26 |

9.00 9.00 |

135.2 132.9 |

| 70 | 19 x 2.10 | 0.5026 | 19.41 | 10.5 | 180.9 |

| 95 | 19 x 2.50 | 0.3546 | 27.51 | 12.5 | 256.3 |

| 120 | 19 x 2.80 | 0.2827 | 34.51 | 14.0 | 321.5 |

| 150 | 37 x 2.25 | 0.2256 | 43.40 | 15.8 | 405.7 |

| 185 | 37 x 2.50 | 0.1827 | 53.68 | 17.5 | 500.9 |

| 240 | 61 x 2.25 | 0.1373 | 71.55 | 20.3 | 671.1 |

| 300 | 61 x 2.50 | 0.1112 | 88.33 | 22.5 | 828.5 |

| 400 | 61 x 2.89 | 0.0832 | 118.04 | 26.0 | 1107.1 |

| 500 | 61 x 3.23 | 0.0666 | 147.45 | 29.1 | 1382.9 |

| 625 | 91 x 2.96 | 0.0534 | 184.73 | 32.6 | 1739.7 |

| 800 | 91 x 3.35 | 0.0417 | 236.62 | 36.9 | 2228.3 |

| 1000 | 91 x 3.74 | 0.0334 | 294.91 | 41.1 | 2777.3 |

BS EN 50182

| Name | Nominal Cross Sectional Area |

No. and Nominal Dia. of wires |

Max. DC. Resistance at20ºC |

Rated Strength |

Approx. Overall Dia. | Approx. Weight |

| BS EN 50182 | mm² | No. X Φ (mm) | Ω/km | kN | mm | kg/km |

| BOX | 18.8 | 7 x 1.85 | 1.7480 | 5.55 | 5.55 | 51.4 |

| ACACIA | 23.8 | 7 x 2.08 | 1.3828 | 7.02 | 6.24 | 64.9 |

| ALMONO | 30.1 | 7 x 2.34 | 1.0926 | 8.88 | 7.02 | 82.2 |

| CEDAR | 35.5 | 7 x 2.54 | 0.9273 | 10.46 | 7.62 | 96.8 |

| DEODAR | 42.2 | 7 x 2.77 | 0.7797 | 12.44 | 8.31 | 115.2 |

| FIR | 47.8 | 7 x2.95 | 0.6875 | 14.11 | 8.85 | 130.6 |

| HAZEL | 59.9 | 7 x 3.30 | 0.5494 | 17.66 | 9.90 | 163.4 |

| PINE | 71.6 | 7 x 3.61 | 0.4591 | 21.14 | 10.8 | 195.6 |

| HOLLY | 84.1 | 7 x 3.91 | 0.3913 | 24.79 | 11.7 | 229.5 |

| WILLOW | 89.7 | 7 x 4.04 | 0.3665 | 26.47 | 12.1 | 245.0 |

| OAK | 118.9 | 7 x 4.65 | 0.2767 | 35.07 | 14.0 | 324.5 |

| MULBERRY | 150.9 | 19 x 3.18 | 0.2192 | 44.52 | 15.9 | 414.3 |

| ASH | 180.7 | 19 x 3.48 | 0.1830 | 53.31 | 17.4 | 496.1 |

| ELM | 211.0 | 19 x 3.76 | 0.1568 | 62.24 | 18.8 | 549.2 |

| POPLAR | 239.4 | 37 x 2.87 | 0.1387 | 70.61 | 20.1 | 659.4 |

| SYCAMORE | 303.2 | 37 x 3.23 | 0.1095 | 89.40 | 22.6 | 835.2 |

| UPAS | 362.1 | 37 x 3.53 | 0.0917 | 106.82 | 24.7 | 997.5 |

| YEW | 479.0 | 37 x 4.06 | 0.0693 | 141.31 | 28.4 | 1319.6 |

| TOTARA | 498.1 | 37 x 4.14 | 0.0666 | 146.93 | 29.0 | 1372.1 |

| RUBUS | 586.9 | 61 x 3.50 | 0.0567 | 173.13 | 31.5 | 1622.0 |

| SORBUS | 659.4 | 61 x 3.71 | 0.0505 | 194.53 | 33.4 | 1822.5 |

| ARAUCARIA | 821.1 | 61 x 4.14 | 0.0406 | 242.24 | 37.3 | 2269.4 |

| RESWOOD | 996.2 | 61 x 4.56 | 0.0334 | 293.88 | 41.0 | 2753.2 |

The above data is approximate and subjected to manufacturing tolerance.

- Next: PVC Coated Copper Electric Housing Wire with Yellow/Green Color

- Previous: All Aluminum Alloy Conductor AAAC ASTM BS IEC DIN CSA 394.5 Kcmil Canton