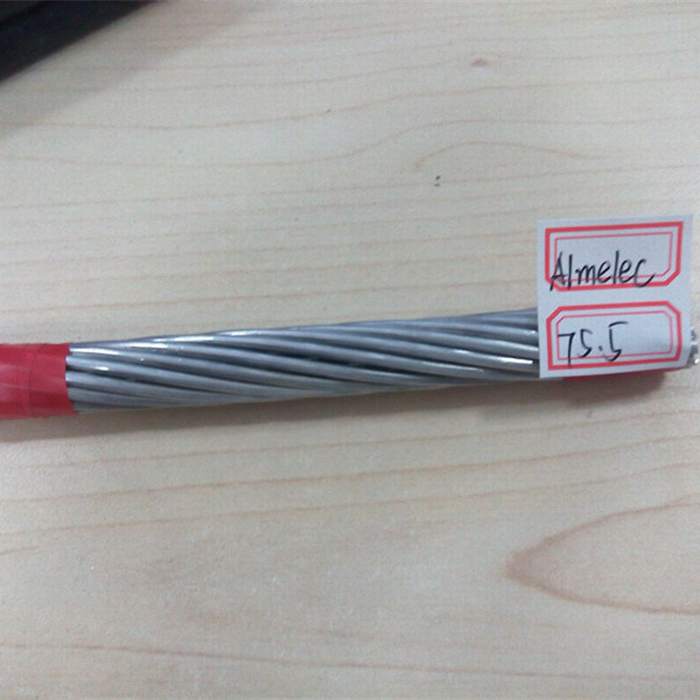

AAAC Aluminum Conductor 70mm2 Aluminum Alloy Conductor

Quick Details

Product Details

Product Description

1.Application

AAAC is mainly used as bare overhead transmission cable and as primary and secondary distribution cable. It is also suitable for laying across basins, rivers and valleys where special geographical teatures exist.

2.Standard

Basic design to BS 3242 / BS EN 50182 / IEC 61089 / ASTM B 399/B 399M / DIN 48201-6 standards

3.Construction

Aluminum alloy(AAAC) contains a small percentage(about 0.6%) of silicon and magenesium elements. It provides several benefits for overhead lines.

1. Strength– About twice that of aluminum 1350(EC)

2. Weight– 20%(approx.) lighter than ACSR conductor of equal diameter.

3. Corrosion resistance– It has a high resistance to atmospheric corrosion which is suitable for coastal and industrial areas.

4. Surface hardness– AAAC’s surface is signficantly harder than aluminum 1350. It is lessliable to damage during installation which is an important advantage of EHV transmission lines where corona and radio interference is a major consideration.

5. Termination– Much simpler jointing accessories required compared to ACSR.

6. AC Resistance– AAAC is a non-magnetic material.

It does not exhibit the magnetic core losses found in ACSR conductor.

4.Electrical Properties

|

Density@20ºC |

2.70 kg/dm |

|

Temperature Coefficient@20°C |

0.00360 (°C) |

|

Resistivity@20°C |

0.0326 Ohms mm²/m |

|

Linear Expansivity |

23 x10-6(°C) |

5.Service Conditions

|

Ambient Temperature |

-5°C – 50°C |

|

Wind Pressure |

80 – 130kg/m² |

|

Seismic Acceleration |

0.12 – 0.05g |

|

Isokeraunic Level |

10 – 18 |

|

Relative Humidity |

5 – 100% |

| ALL ALUMINIUM ALLOY CONDUCTOR DIN 48201 | ||||||

| Nominal area |

Actual area |

Stranding and wire diameter |

Overall diameter |

Linear mass |

Nominal Breaking Load | Max. DC resistance at 20ºC |

| mm2 | mm2 | No./mm | mm | kg/km | daN | Ω/km |

| 16 | 15.89 | 7/1.71 | 5.1 | 43 | 444 | 2.091 |

| 25 | 24.25 | 7/2.10 | 6.3 | 66 | 677 | 1.3703 |

| 35 | 34.36 | 7/2.50 | 7.5 | 94 | 960 | 0.9669 |

| 50 | 49.48 | 7/3.00 | 9.0 | 135 | 1382 | 0.6714 |

| 50 | 48.36 | 19/1.80 | 9.0 | 133 | 1350 | 0.6905 |

| 70 | 65.82 | 19/2.10 | 10.5 | 181 | 1838 | 0.5073 |

| 95 | 93.27 | 19/2.50 | 12.5 | 256 | 2605 | 0.3579 |

| 120 | 117 | 19/2.80 | 14.0 | 322 | 3268 | 0.2854 |

| 150 | 147 | 37/2.25 | 15.2 | 406 | 4109 | 0.2274 |

| 185 | 181 | 37/2.5 | 17.5 | 501 | 5073 | 0.1842 |

| 240 | 242.54 | 61/2.25 | 20.2 | 670 | 6774 | 0.1383 |

| 300 | 299.43 | 61/2.50 | 22.5 | 827 | 8363 | 0.112 |

| 400 | 400.14 | 61/2.89 | 26.0 | 1104 | 11176 | 0.0838 |

| 500 | 499.83 | 61/3.23 | 29.1 | 1379 | 13960 | 0.06709 |

| 625 | 626.2 | 91/2.96 | 32.6 | 1732 | 17490 | 0.054 |

| 800 | 802.1 | 91/3.35 | 36.9 | 2218 | 22402 | 0.0418 |

| 1000 | 999.71 | 91/3.74 | 41.1 | 2767 | 27922 | 0.0335 |

Delivery Details : 3-30 days.

1. Strict quality control system, excellent quality with reasonable price.

2. Strong and Professional R&D team to meet your specific needs.

3. Rapid delivery and feedback. Faster lead time than our competitors.

4. OEM service available based on official & legal authorization.

5. Free sample is available.

6. Appointed shipping company is acceptable.

- Next: 300/500V 70mm Flexible Copper Welding Rubber Insulated Cable

- Previous: 0.6/1kv XLPE Insulation ABC Cable Overhead Transmission Line