600V, Building Wire, Thhn/Thwn/Twn75/T90, 8AWG

Product Description

Application

Type THHN or THWN-2* conductors are primarily used in conduit and cable

trays for services, feeders and branch circuits in commercial or industrial applications as

specified in the National Electrical Code®2

? When used as Type THHN, conductor is suitable for use in dry locations at temperatures

not to exceed 90°C

? When used as Type THWN-2*, conductor is suitable for use in wet or dry locations at

temperatures not to exceed 90°C or not to exceed 75°C when exposed to oil or coolant

? When used as Type MTW, conductor is suitable for use in wet locations or when exposed

to oil or coolant at temperatures not to exceed 60°C or dry locations at temperatures not to

exceed 90°C (with ampacity limited to that for 75°C conductor temperature per NFPA 79)

? Conductor temperatures not to exceed 105°C in dry locations when rated AWM and used as

appliance wiring material. Voltage for all applications is 600 volts

STANDARDS & REFERENCES

Type THHN or THWN-2* or MTW (also AWM) meets or exceeds all applicable

ASTM specifications, UL Standard 83, UL Standard 1063 (MTW), Federal Specification

A-A-59544 and requirements of the National Electrical Code.® RoHS Compliant.

CONSTRUCTION

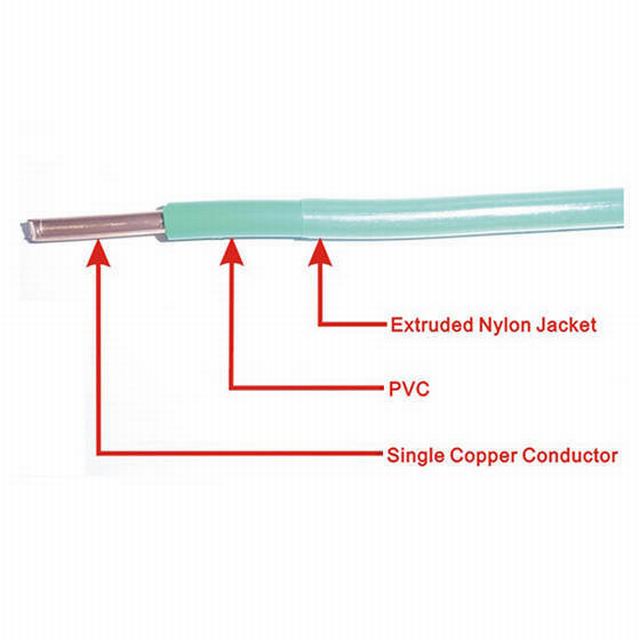

?Type THHN or THWN-2* or MTW copper conductors are annealed (soft) copper,

insulated with a tough heat and moisture resistant polyvinyl chloride (PVC), over which a

nylon (polyamide) or UL-listed equal jacket is applied

? Available in black, white, red, blue, green, yellow, brown, orange and grey; some colors

standard, some subject to economic order quantity

SPECIFICATIONS

? MTW or THHN or THWN-2:

Conductors shall be UL-listed Type MTW or THHN or THWN-2* gasoline and oil

resistant II, suitable for operations at 600 volts as specified in the National Electrical

Code.® Sizes 14 through 6 AWG shall be rated VW-1. Conductors shall be annealed

copper, insulated with high-heat and moisture resistant PVC, jacketed with abrasion,

moisture, gasoline and oil resistant nylon or listed equivalent, as manufactured by

Southwire Company or approved equal.

? AWM:

Conductors shall be UL-listed Type THHN or THWN-2* or MTW or AWM, suitable for

operation at 600 volts at conductor temperatures not to exceed 105°C.

Building wire is generally used to carry electrical current to all external uses of power in a building or dwelling. This product is utilized in the construction of almost every industrial, residential and commercial building. The most popular type is THHN building wire.

THHN Wire stands for Thermoplastic High Heat-resistant Nylon coated. THHN can come in stranded or solid conductors depending on the size. It is either manufactured in copper or aluminum and covered in a PVC (polyvinyl chloride) insulation with a nylon jacket. THHN is UL listed with a rated 90 degrees Celsius in dry locations or 75 degrees Celsius in wet applications with a THWN rating. The vast majority of THHN building wire carries a dual rating on the cable marked THHN / THWN for both the wet and dry temperature rating. THHN building wire may also be used for wiring of machine tools, control circuits or on certain appliances.

THHN building wire has several main distinctions compared to other building wire products. THHN uses a thinner PVC insulation which is a key factor in terms of its electrical properties. This thinner insulation can often lead to a current leakage and even a breakdown during chemical or environmental exposure. The PVC insulation in THHN also creates a toxic smoke when burned therefore making it undesireable in certain applications.

THHN is not a very flexible product due to its nylon coating. This can often be a factor for many contractors or end users since there is usually a preference to use a product that saves energy and time during installation. However, THHN building wire has grown in popularity since it is a cost effective alternative compared to other types of building wire such as XHHW building wire. Despite some of its down falls, many users of THHN building wire have found this products to be sufficient for meeting their projects specifications.

- Next: Flexible Electrical Cable H05VV-F, Rvv

- Previous: Duplex Service Drop, ACSR Neutral, 1/0AWG Heeler