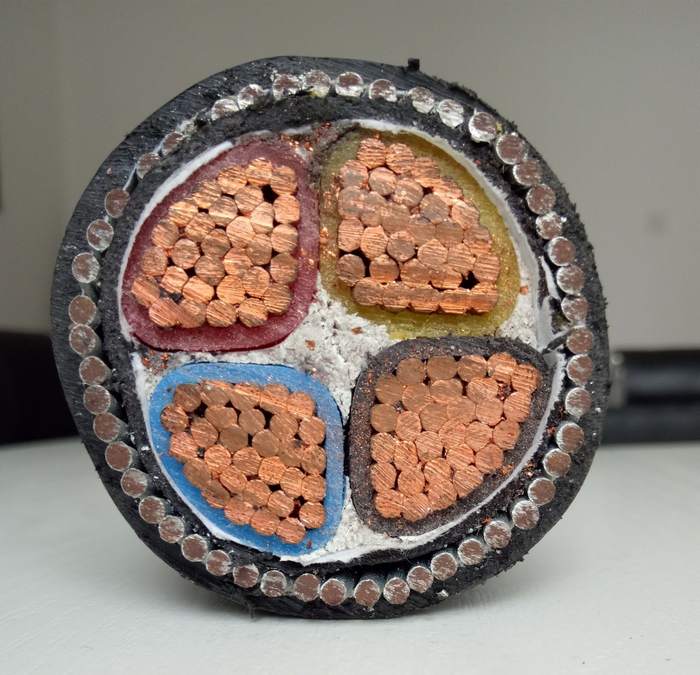

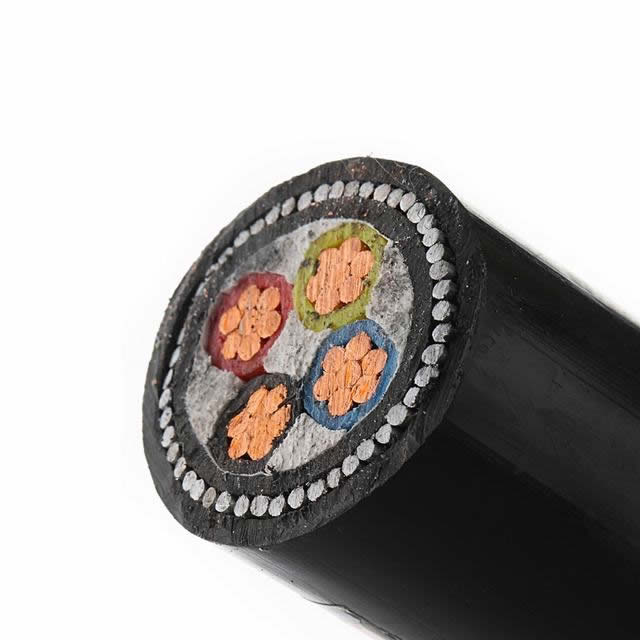

4 Core 120mm Copper or Aluminum XLPE Insulated Armoured Power Cable

Product Description

1. Standard: According to Chinese national standard GB 12706 and GB12666.6(Equal to IEC60502 and IEC60331),also can do by standard of ASTM,BS,GB,DIN and AS/NZS or other standards as request.

2. Rated Voltage:0.6/1KV

3. Construction:

Conductor:Copper or Aluminium

Insulation:XLPE/PVC

Inner sheath:PVC or PE

Armoured:Galvanized steel tape or galvanized steel wire

Outer Sheath:PVC or PE

NO. of cable cross: 1 core(Single core),2cores(Double cores),3cores, 4cores(4 equal-section-area cores OR 3 equal-section-area+1 small section area neutral core),5cores(5 3 equal-section-area cores+2 small area neutral cores OR 4 equal-section-area +1 small area neutral cores).We provide armored type and non-armored type for the cables stated above.

Also can do according to the customer’s request.

4. Characters:

a.Max Long-time operating temperature of PVC insulated cable is 70°C

b.Installing temperature of cable should not be less than 0°C

c.Max short-circuit temperature is not exceed 160°C,Not more than5 Sec.

d.Permitting bending radius cable: Not less than 10 D times (D:external diameter of cable)

5. Description & Application:

| Nominal | Diameter of | Nominal | Nominal | Nominal Steel | Nominal | Overall |

| Cross | Conductor | Insulation | Inner | Wire dia. | Sheath | Diameter |

| Section | (Approx.) | thickness | Covering | thickness | (Approx.) | |

| thickness | ||||||

| mm² | mm | mm | mm | mm | mm | mm |

| 4×1.5 | 1.4 | 0.7 | 1 | 0.8 | 1.8 | 14 |

| 4×2.5 | 1.8 | 0.7 | 1 | 0.8 | 1.8 | 14.9 |

| 4×4 | 2.3 | 0.7 | 1 | 1.25 | 1.8 | 17 |

| 4×6 | 2.8 | 0.7 | 1 | 1.25 | 1.8 | 18.2 |

| 4×10 | 3.6 | 0.7 | 1 | 1.25 | 1.8 | 20.2 |

| 4×16 | 4.5 | 0.7 | 1 | 1.6 | 1.8 | 23 |

| 4×25 | 5.6 | 0.9 | 1 | 1.6 | 1.8 | 26.7 |

| 4×35 | 6.7 | 0.9 | 1 | 1.6 | 1.9 | 29.5 |

| 4×50 | 8 | 1 | 1 | 2 | 2.1 | 34.2 |

| 4×70 | 9.4 | 1.1 | 1.2 | 2 | 2.2 | 38.8 |

| 4×95 | 11 | 1.1 | 1.2 | 2 | 2.3 | 42.9 |

| 4×120 | 12.4 | 1.2 | 1.4 | 2.5 | 2.5 | 48.6 |

| 4×150 | 13.8 | 1.4 | 1.4 | 2.5 | 2.7 | 53.2 |

| 4×185 | 15.3 | 1.6 | 1.4 | 2.5 | 2.8 | 58.1 |

| 4×240 | 17.5 | 1.7 | 1.6 | 2.5 | 3.1 | 64.8 |

| 4×300 | 19.5 | 1.8 | 1.6 | 2.5 | 3.2 | 70.4 |

| 4×400 | 22.6 | 2 | 1.8 | 3.15 | 3.6 | 81.3 |

6. Advantages:

a. Excellent electric and mechanical characteristics

b. Best Resistance chemical corrosion and heat-ageing,environment stress and flame-retardant

c. Simple in structure

d. Convenient to use

e. Light weight,perfect bending properties

Core NO. & Nominal Cross-section Area as reference:

| No. of Core | 1 | 2 | 3 | 3+1 | 4 | 3+2 | 4+1 |

| Section Area (mm2) |

4~500 | 2.5~500 | 2.5~300 | 4~300 | 2.5~300 | 2.5~300 | 4~300 |

- Next: Overhead Bundled Aluminum Quadruplex Service Drop Cable

- Previous: High Quality Aluminium Conductor AAC Ant BS215-1 Standard

Contact us

Similar Or Related

-

0.6/1kv 4 Core 120mm2 Swa Armoured PVC Insualted Underground Cable Price

-

0.6/1kv 4 Core Armoured Cable 120mm PVC Armoured Power Cable

-

4 Core 35mm ABC Cable HDPE Sheathed Cable Quadruplex Aerial Cable

-

0.6/1kv PVC Insulated 16mm2 25mm2 35mm2 50mm2 4 Core Armoured Power Copper Cable

-

4 Core 120mm Copper or Aluminum XLPE Insulated Armoured Power Cable