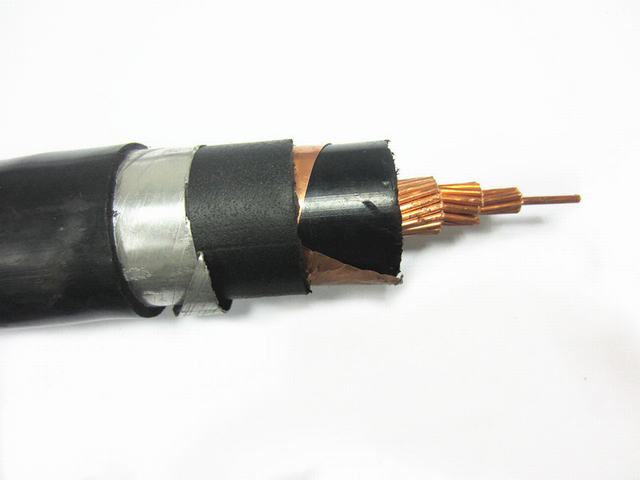

33kv/22kv/11kv Cu/XLPE/Swa/PVC Armoured Power Cables

Product Description

1kv-35 kv multi-cores/ copper or aluminium conductor/ XLPE insulation / copper tape or copper wire screen / galvanized steel wire armored / PVC or PE sheath / power cable,

The products are mainly complying with iec 60502 standard, also can be produced according to OEM requirements and other standards, such as bs standard, DIN standard, ASTM standard, etc.

Voltage grade is up to 35kv, cross-section area can be up to 400 sqmm (copper or aluminiun conductor). Conductor long-time operating temperature is 90 degrees. In short circuit, conductor highest temperature should be not more than 250 degrees.

Laying conditions: For lyaing under ground with large different altitude, be able to bear external machanical force and moderate pulling force.

0.6/1kV cable-26/35kV Cable, XLPE Insulated Steel Tape Armoured PVC Sheathed Power Cable CU/XLPE/STA/PVC

-Conductor:

Solid or stranded Aluminu

-Insulation:

Cross-linked polyethylene( XLPE or PVC)

-Circuit Identication:

The insulation shall be red, black

-Filler:

Polypropylene lament with lapped binding tape

-Inner Sheath:

Polyvinyl chloride (Black)

-Armor:

Galvanized steel wire/steel tape/Unarmored/Aluminum wire

-Core-covering:

Binding tape

-Outer Sheath:

Polyvinyl chloride (Black)

-Application:

For use in ducts, trays and direct burial in ground. The cable is subject to immerse in water all the time.

-Standards / Testing Specications:

IEC 60502-1.

Installation

This cable can be installed in duct, tray or direct burial. It is recommended that the installation instructions indicated by the Local Electric Code, or any equivalent, be followed, so that the safeguarding of persons and the integrity of the product will not be affected by eciencies in the installation.

Detailed Product Description

1.8.7/15kv XLPE INSULATED POWER CABLE

XLPE insulated power cable has a number of advantages over paper insulated and PVC insulated cable. XLPE cable has high electric strength, mechanical strength, high-ageing resisting, environmetal stress resisting antichemical corrossion, and it is simple construction, using convenient and higher operating of long term temperature. It can be laid with no drop restriction.

Various of flame-retardant and non-flame retardant XLPE cable can be manufactured with three technology(peroxide, silane and irradiation crosslinking). The flame-retardant cable covers all kinds of low-smoke low-halogen low-smoke halogen free, and non-smoke nonhalogented and three classes of A, B, C.

Our XLPE cable can be manufactured according to companys specification which is equivalent to IEC 60502, IEC 60332, and IEC 60754. Some of indexes are superior to above international standard IEC.

Some of special XLPE cable can be manufactured according to the other standards required by customs.

XLPE cable having higher long-term working temperature and greater current rating, at the same environment XLPE cable may be reduced size(nominal cross-section)1or 2 class in comparison with paper and PVC cable. This is not only improve the quality and properties of products, but also reduce cables production costs.

| Class 2 stranded conductors for single-core and multi-core cables | |||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Nominal crosssectional area | Minimum number of wires in the conductor | Maximum resistance of conductor at 20ºC | |||||||

| Circular | Circular compacted | Shaped | Annealed copper conductor | Aluminium or aluminium alloy conductor | |||||

| Cu | Al | Cu | Al | Cu | Al | Plain wires | Metal-coated wires | ||

| mm2 | Ω/KM | Ω/KM | Ω/KM | ||||||

| 0.5 | 7 | 36 | 36.7 | ||||||

| 0.75 | 7 | 24.5 | 24.8 | ||||||

| 1 | 7 | 18.1 | 18.2 | ||||||

| 1.5 | 7 | 6 | 12.1 | 12.2 | |||||

| 2.5 | 7 | 6 | 7.41 | 7.58 | |||||

| 4 | 7 | 6 | 4.61 | 4.7 | |||||

| 6 | 7 | 6 | 3.08 | 3.11 | |||||

| 10 | 7 | 7 | 6 | 6 | 1.83 | 1.84 | 3.08 | ||

| 16 | 7 | 7 | 6 | 6 | 1.15 | 1.16 | 1.91 | ||

| 25 | 7 | 7 | 6 | 6 | 6 | 6 | 0.727 | 0.734 | 1.2 |

| 35 | 7 | 7 | 6 | 6 | 6 | 6 | 0.524 | 0.529 | 0.868 |

| 50 | 19 | 19 | 6 | 6 | 6 | 6 | 0.387 | 0.391 | 0.641 |

| 70 | 19 | 19 | 12 | 12 | 12 | 12 | 0.268 | 0.27 | 0.443 |

| 95 | 19 | 19 | 15 | 15 | 15 | 15 | 0.193 | 0.195 | 0.32 |

| 120 | 37 | 37 | 18 | 15 | 18 | 15 | 0.153 | 0.154 | 0.253 |

| 150 | 37 | 37 | 18 | 15 | 18 | 15 | 0.124 | 0.126 | 0.206 |

| 185 | 37 | 37 | 30 | 30 | 30 | 30 | 0.0991 | 0.1 | 0.164 |

| 240 | 37 | 37 | 34 | 30 | 34 | 30 | 0.0754 | 0.0762 | 0.125 |

| 300 | 61 | 61 | 34 | 30 | 34 | 30 | 0.0601 | 0.0607 | 0.1 |

| 400 | 61 | 61 | 53 | 53 | 53 | 53 | 0.047 | 0.0475 | 0.0778 |

| 500 | 61 | 61 | 53 | 53 | 53 | 53 | 0.0368 | 0.0369 | 0.0605 |

| 630 | 91 | 91 | 53 | 53 | 53 | 53 | 0.0283 | 0.0286 | 0.0469 |

| 800 | 91 | 91 | 53 | 53 | 0.0221 | 0.0224 | 0.0367 | ||

| 1000 | 91 | 91 | 53 | 53 | 0.0176 | 0.0177 | 0.0291 | ||

- Next: Control Cable, Copper PVC Insulated 19X2.5mm2

- Previous: All Aluminum Conductor XLPE Insulated ABC Cable