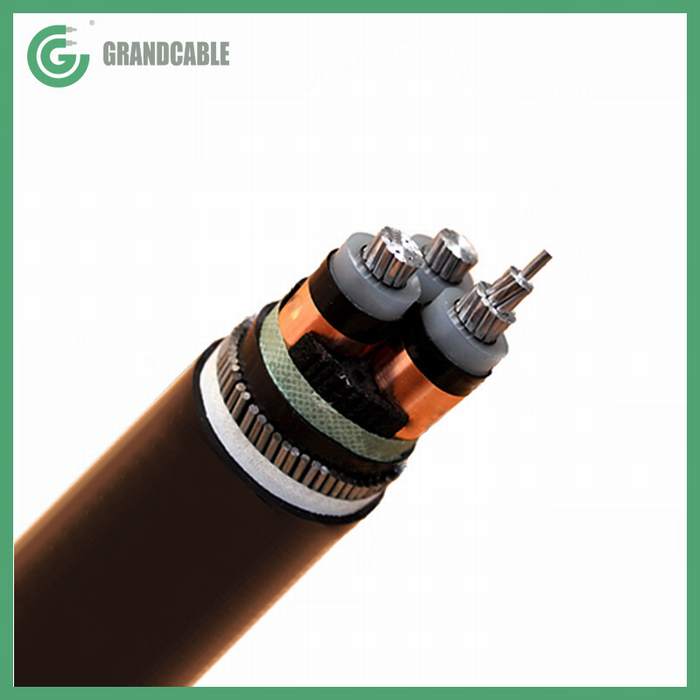

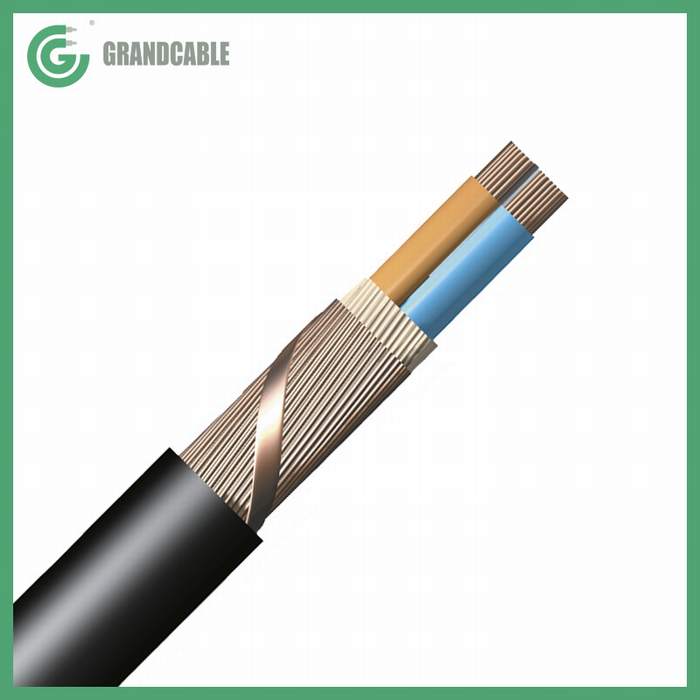

26/35kv XLPE Insulated 3 Core, 6mm Armoured Cable (SWA cable)

Product Description

1. Description

Construction: Compacted stranded circular copper conductor, extruded semi-conducting compound as conductor shield, cross-linked polyethylene (XLPE) insulation, semi-conducting compound as insulation shield, copper tape or combination of copper wire and tape as metallic screen, three cores assembled together with non-hygroscopic polypropylene filler, wrapped with binder tape, PVC inner covering as armoring bedding, galvanized steel wire armored, PVC or PE outer sheath.

2. Operating Characteristics

Rated voltage U0/U(Um): 21/35 (40.5)kV

U0 is the rated power frequency voltage between conductor and earth or metallic screen for which the cable is designed;

U is the rated power frequency voltage between conductors for which the cable is designed;

Um is the maximum value of the "highest system voltage" for which the equipment may be used.

Max. Permissible continuous operating temperature of conductor: 90 ° C

Max. Temperature of conductor during short-circuit (5s max. Duration) shall not exceed: 250 ° C

The ambient temperature under installation should not be lower than: 0 ° C

The bending radius of cable is recommended as following:

For single core cable: Not less than 15 times of the diameter of cable

For three core cable: Not less than 12 times of the diameter of cable

When the armored single core cable used for Alternative Current(AC) system, the armoring material should be non-magnetic.

3. Application

The cable is used for fixed installations such as electric power distribution networks or industrial installations, which is laid indoors, outdoors, in tunnel, in cable trench, or direct in ground, able to bear external mechanical force and certain pulling force.

4. Manufacturing Standards

IEC 60502-2 and Chinese National Standard GB/T 12706-2008 We can produce above cables according to popular international standards such as ASTM, BS, DIN, NF &AS/NZ also.

NOTE:

If you want to know more details about this kind of products, please don’t hesitate to email us. we will reply to you ASAP.

| Size (sq.mm) |

Nominal thickness of XLPE insulation(mm) | Approx. thickness of copper tape screen (mm) | Approx. diameter of steel wire (mm) | Nominal thickness of PVC or PE(mm) | Approx. overall diameter of finished cable(mm) | Max. conductor D.C resistance @ 20 0 C (Ω/km) |

| 3×50 | 10.5 | 0.10 | 3.15 | 3.8 | 92.3 | 0.387 |

| 3×70 | 10.5 | 0.10 | 3.15 | 3.9 | 96.4 | 0.268 |

| 3×95 | 10.5 | 0.10 | 3.15 | 4.1 | 100.4 | 0.193 |

| 3×120 | 10.5 | 0.10 | 3.15 | 4.2 | 103.8 | 0.153 |

| 3×150 | 10.5 | 0.10 | 3.15 | 4.3 | 107.8 | 0.124 |

| 3×185 | 10.5 | 0.10 | 3.15 | 4.4 | 111.5 | 0.0991 |

| 3×240 | 10.5 | 0.10 | 3.15 | 4.6 | 117.3 | 0.0754 |

| 3×300 | 10.5 | 0.10 | 3.15 | 4.7 | 122.1 | 0.0601 |

| 3×400 | 10.5 | 0.10 | 3.15 | 5.0 | 130.0 | 0.0470 |

- Next: Middle Voltage 20kv Aluminum Conductor XLPE Insulated Steel Tape Armored Power Cable

- Previous: 3*150mm2 Copper Aluminium XLPE Insulated Steel-Tape Armoured PVC Sheathed Powe Cable

Contact us

Similar Or Related

-

15kV 3 Core 4/0AWG Aluminum Conductor XLPE Insulated SWA Armored MV Power Cable

-

XLPE Insulated Aerial Service Drop Cable Conductor #3AWG Duplex ICEA S-66-524 NEMA WC7

-

3Cx185mm2 XLPE Insulated Copper Tape Screened Galvanized Steel Wire Armored Power Cable 33kV

-

0.6/1kV 4Cx500mm2 Copper Conductor PVC Insulated SWA Armored LV Power Cable IEC 60502-1

-

Low Voltage Single Core Power Cable 1X300 mm2 N2XCH CU/XLPE/CWS/LSF 0.6/1kV

-

26/35kv XLPE Insulated 3 Core, 6mm Armoured Cable (SWA cable)