21/35kv 3X90mm2 Copper XLPE Insualted PVC Sheathed Power Cable

Product Description

CU/XLPE/PVC(or PE) Power Cable

1. Description

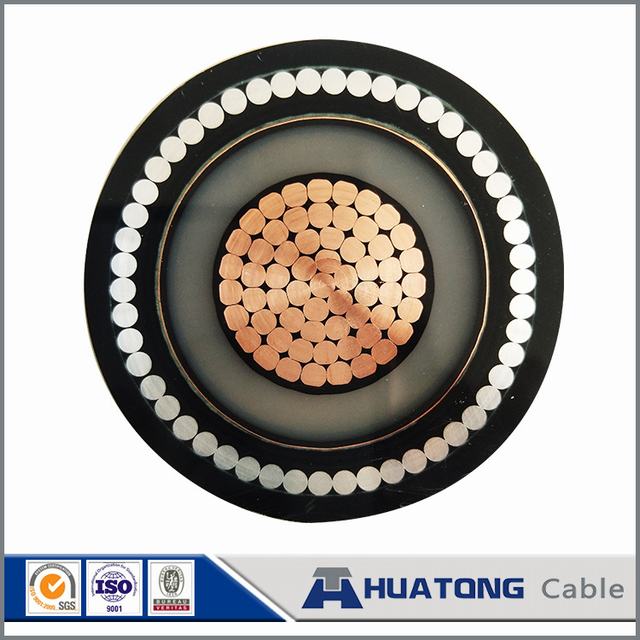

Construction: Compacted stranded circular copper conductor, extruded semi-conducting compound as conductor shield, cross-linked polyethylene (XLPE) insulation, semi-conducting compound as insulation shield, copper tape or combination of copper wire and tape as metallic screen, three cores assembled together with non-hygroscopic polypropylene filler, wrapped with binder tape, PVC or PE outer sheath.

2. Operating Characteristics

Rated voltage U0/U(Um): 21/35(40.5)kV

U0 is the rated power frequency voltage between conductor and earth or metallic screen for which the cable is designed;

U is the rated power frequency voltage between conductors for which the cable is designed;

Um is the maximum value of the "highest system voltage" for which the equipment may be used.

Max. Permissible continuous operating temperature of conductor: 90 ° C

Max. Temperature of conductor during short-circuit (5s max. Duration) shall not exceed: 250 ° C

The ambient temperature under installation should not be lower than: 0 ° C

The bending radius of cable is recommended as following:

For single core cable: Not less than 20 times of the diameter of cable

For three core cable: Not less than 15 times of the diameter of cable

3. Application

The cable is used for fixed installations such as electric power distribution networks or industrial installations, which is laid indoors, outdoors, in tunnel or in cable trench, unable to bear external mechanical force.

Single core cable in magnetic duct is not permissible.

4. Manufacturing Standards IEC 60502-2 and Chinese National Standard GB/T 12706-2008 We can produce above cables according to popular international standards such as ASTM, BS, DIN, NF &AS/NZ also.

Main technical data of 21/35KV, three cores, Copper conductor, XLPE insulated, and PVC or PE sheath cable ;

CABLE CONSTRUCTION: 21/35KV CU/XLPE/PVC or PE

| Size | Nominal thickness of XLPE insulation(mm) | Approx. thickness of copper tape screen (mm) | Nominal thickness of PVC or PE(mm) | Approx. overall diameter of finished cable(mm) | Max. conductor D.C resistance @ 20 0 C (Ω/km) |

| 3x50mm 2 | 9.3 | 0.10 | 3.3 | 74.7 | 0.387 |

| 3x70mm 2 | 9.3 | 0.10 | 3.4 | 78.6 | 0.268 |

| 3x95mm 2 | 9.3 | 0.10 | 3.5 | 82.3 | 0.193 |

| 3x120mm 2 | 9.3 | 0.10 | 3.6 | 85.6 | 0.153 |

| 3x150mm 2 | 9.3 | 0.10 | 3.7 | 89.3 | 0.124 |

| 3x185mm 2 | 9.3 | 0.10 | 3.8 | 93.0 | 0.0991 |

| 3x240mm 2 | 9.3 | 0.10 | 4.0 | 98.7 | 0.0754 |

| 3x300mm 2 | 9.3 | 0.10 | 4.2 | 103.4 | 0.0601 |

| 3x400mm 2 | 9.3 | 0.10 | 4.4 | 110.9 | 0.0470 |

- Next: 12/20kv Aluminum Conductor XLPE Insulated Power Cable

- Previous: 18/30kv Copper Conductor XLPE Insulated Steel Tape Armored Power Cable