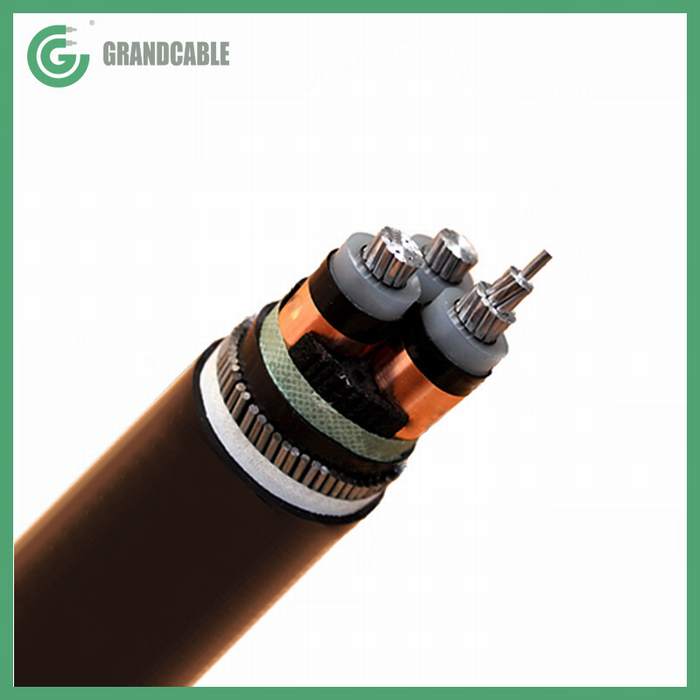

11kv 1*185mm2 XLPE Insulation Sheath Copper Electric Cable Wire

Product Description

1.Application

1)XLPE insulated copper power cable has a number of advantages compared with paper insulated and PVC insulated cables.

2)XLPE Copper cable has high electric property, mechanical property, heat aging performance, environmental stress crack resistance, chemical corrosion resistance, and it also has a simple structure, convenient operation and it is not restricted by laying in the large difference of level.

3) It can be applied at a high temperature of 90 degrees for a long time.

4)Flame-retardant and non-flame-retardant XLPE cables can be manufactured by three kinds of technological processes: peroxidation, silanization, and irradiation.

5)The flame-retardant cable covers three classes of A, B, C, and low-smoke low-halogen, low-smoke non-halogen cables.

2.Standard

Our XLPE Copper cable is produced according to IEC 60502, IEC60332, and IEC 60754, even some of our indexes are superior to the above international IEC standards. Meanwhile, we can produce cables according to other standards and can design the XLPE cables with some certain special properties according to customers’ requirements.

XLPE Copper cable can be applied at high temperatures for a long time and has a bigger current capacity. In the same environmental conditions, compared with paper insulated and PVC insulated cables, XLPE cable can lessen the cross-section by 1 or 2 grades.

3.Specification

| Size | Nominal thickness of XLPE insulation(mm) |

Approx. the thickness of the copper tape screen (mm) |

Nominal thickness of PVC or PE(mm) |

Approx. overall diameter of finished cable(mm) |

Max. conductor D.C resistance @ 200C (Ω/km) |

| 1x25mm2 | 3.4 | 0.12 | 1.8 | 20.3 | 0.727 |

| 1x35mm2 | 3.4 | 0.12 | 1.8 | 21.3 | 0.524 |

| 1x50mm2 | 3.4 | 0.12 | 1.8 | 22.4 | 0.387 |

| 1x70mm2 | 3.4 | 0.12 | 1.8 | 24.1 | 0.268 |

| 1x95mm2 | 3.4 | 0.12 | 1.8 | 25.7 | 0.193 |

| 1x120mm2 | 3.4 | 0.12 | 1.8 | 27.1 | 0.153 |

| 1x150mm2 | 3.4 | 0.12 | 1.8 | 28.7 | 0.124 |

| 1x185mm2 | 3.4 | 0.12 | 1.9 | 30.5 | 0.0991 |

| 1x240mm2 | 3.4 | 0.12 | 2.0 | 33.1 | 0.0754 |

| 1x300mm2 | 3.4 | 0.12 | 2.0 | 35.1 | 0.0601 |

| 1x400mm2 | 3.4 | 0.12 | 2.1 | 38.5 | 0.0470 |

| 1x500mm2 | 3.4 | 0.12 | 2.2 | 42.2 | 0.0366 |

| 1x630mm2 | 3.4 | 0.12 | 2.3 | 46.3 | 0.0283 |

| 1x800mm2 | 3.4 | 0.12 | 2.5 | 50.4 | 0.0221 |

| Nominal Cross Section | Approx. Overall Diameter of Conductor | Nominal Thickness of XLPE Insulation | Nominal Thickness of PVC Inner Sheath | The diameter of Al Wires | Nominal Thickness of PVC Outer Sheath | Approx.Overall Diameter | Approx. Weight | |||||

| Cu Conductor | Al Conductor | |||||||||||

| AWA | AWA | UnAr | AWA | UnAr | AWA | UnAr | AWA | UnAr | AWA | |||

| mm2 | mm | mm | mm | mm | mm | mm | mm | mm | kg/km | kg/km | kg/km | kg/km |

| 1.5 | 1.6 | 0.7 | – | – | 1.4 | – | 5.7 | – | 44 | – | – | – |

| 2.5 | 2.0 | 0.7 | – | – | 1.4 | – | 6.2 | – | 57 | – | – | – |

| 4 | 2.6 | 0.7 | – | – | 1.4 | – | 6.7 | – | 74 | – | – | – |

| 6 | 3.1 | 0.7 | – | – | 1.4 | – | 7.3 | – | 96 | – | – | – |

| 10 | 3.8 | 0.7 | 1.0 | 0.8 | 1.4 | 1.4 | 7.9 | 12.4 | 134 | 235 | 74 | 175 |

| 16 | 4.8 | 0.7 | 1.0 | 0.8 | 1.4 | 1.4 | 8.9 | 13.4 | 196 | 307 | 99 | 209 |

| 25 | 6.0 | 0.9 | 1.0 | 0.8 | 1.4 | 1.4 | 10.6 | 15.1 | 289 | 417 | 139 | 267 |

| 35 | 7.1 | 0.9 | 1.0 | 0.8 | 1.4 | 1.4 | 11.7 | 16.2 | 382 | 522 | 172 | 309 |

| 50 | 8.4 | 1.0 | 1.0 | 1.25 | 1.4 | 1.5 | 13.2 | 18.7 | 503 | 710 | 220 | 427 |

| 70 | 10.0 | 1.1 | 1.0 | 1.25 | 1.4 | 1.5 | 15.0 | 20.5 | 702 | 936 | 293 | 522 |

| 95 | 11.7 | 1.1 | 1.0 | 1.25 | 1.5 | 1.5 | 16.8 | 22.4 | 950 | 1209 | 384 | 638 |

| 120 | 13.3 | 1.2 | 1.0 | 1.6 | 1.5 | 1.6 | 18.6 | 25.1 | 1186 | 1531 | 469 | 806 |

| 150 | 14.5 | 1.4 | 1.0 | 1.6 | 1.5 | 1.6 | 20.4 | 26.7 | 1458 | 1820 | 567 | 923 |

| 185 | 16.4 | 1.6 | 1.0 | 1.6 | 1.5 | 1.7 | 22.7 | 29.2 | 1810 | 2219 | 698 | 1105 |

| 240 | 18.7 | 1.7 | 1.0 | 1.6 | 1.6 | 1.8 | 25.4 | 31.9 | 2348 | 2802 | 889 | 1335 |

| 300 | 20.4 | 1.8 | 1.0 | 1.6 | 1.7 | 1.8 | 27.4 | 33.7 | 2917 | 3393 | 1091 | 1568 |

| 400 | 23.2 | 2.0 | 1.2 | 2.0 | 1.8 | 2.0 | 30.9 | 38.5 | 3713 | 4377 | 1379 | 2043 |

| 500 | 26.4 | 2.2 | 1.2 | 2.0 | 1.9 | 2.1 | 34.7 | 42.3 | 4770 | 5512 | 1767 | 2510 |

| 630 | 30.0 | 2.4 | 1.2 | 2.0 | 2.1 | 2.2 | 39.1 | 46.5 | 6105 | 6914 | 2248 | 3058 |

| 800 | 34.0 | 2.6 | 1.4 | 2.5 | 2.2 | 2.4 | 43.6 | 52.6 | 7893 | 9008 | 2867 | 3981 |

| 1000 | 41.4 | 2.8 | 1.4 | 2.5 | 2.3 | 2.5 | 51.6 | 60.8 | 10189 | 11524 | 3690 | 5025 |

We could produce most of the standards cables, such as ASTM, BS, CSA, DIN, GB and IEC Standards, etc.

ISO9001:2008, OHSAS, CCC, TUV Certifications.

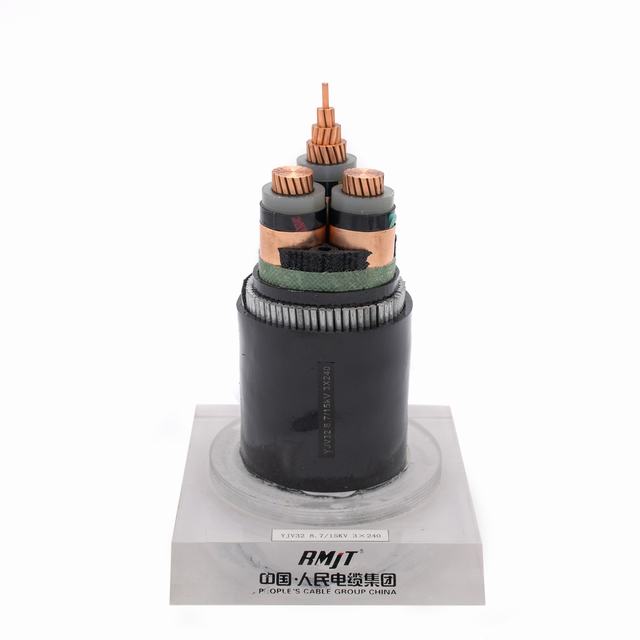

People’s Cable Group Co., Ltd, a professional wires and cables manufacturer for 27 years in China. we mainly produce power cables, control cables, aerial overhead cables(ABC, AAC ACSR, and AAAC cables), etc. Standards Supported: ASTM, BS, CSA, IEC, DIN, and GB, etc.

1. Factory: 160000 square meters, available for OEM;

2. Lead time: 5-7 working days after payment received;

3. Authentication: TUV, OHSAS, CCC, ISO9001:2008;

4. Guarantee: 20 years;

5. QC inspection: Strict inspection before delivery;

After-sales Service:

1. All our cables will be tested well in production and before delivery.

2. Please contact us if any problem, we will respond within 24 hours.

- Next: Low Voltage Yjlv Power Cable Price

- Previous: 0.6/1kv Low Voltage 4X70+1X35mm2 Yjv XLPE Insulated Swa Armoured Electric Power Cables

Contact us

Similar Or Related

-

15kV 3 Core 4/0AWG Aluminum Conductor XLPE Insulated SWA Armored MV Power Cable

-

15kV 1 Core 500 MCM Aluminimum Conductor XLPE Insulated Power Cable AWA Armored Wire Armoured

-

70mm2 6.35/11kV 3 Core XLPE Insulated Cu SWA Armored Electric Cable IEC 60502-2

-

Electric XLPE Power Cable 11kV PILC Cu 3 Core 120mm2 Armoured IEC 60502-2

-

11kv 1*185mm2 XLPE Insulation Sheath Copper Electric Cable Wire