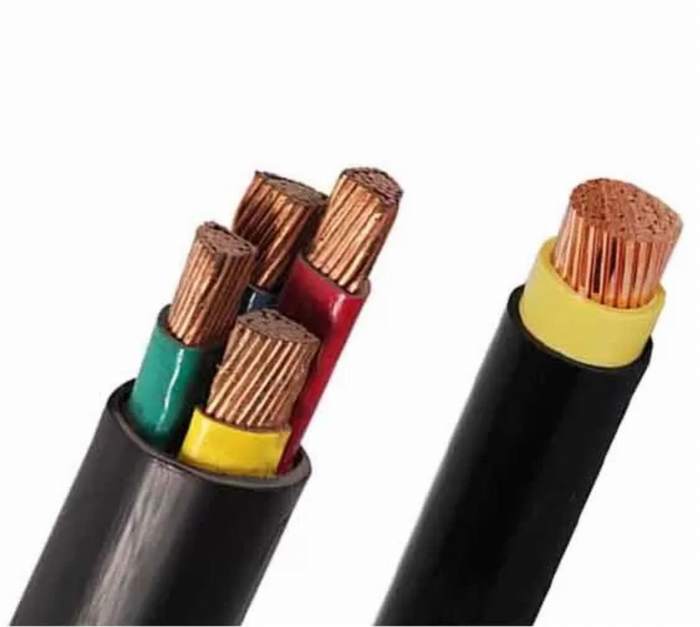

0, 6/1 Kv Cu Conductor PVC/XLPE Insulated Power Cable

Product Description

Application:

Distribution power cable for static application, mostly in ground, but also in water, within facilities, in cable canals, in concrete, in conditions requiring increased electric protection and protection against mechanical damages. Used in electric power plants, transformer stations, industrial plants, metropolitan networks and other electric plants. Concentric conductor can be used as neutral, protective or earth connection, and if there is a danger of damages caused by digging, it acts as protection against contact voltage, in case of rough insulation damage. Corrugated concentric conductor construction enables establishing of several cable connections without conductor cutting.

Standards:

HRN HD 603 S1

IEC 60502-1

DIN VDE 0276 part 603

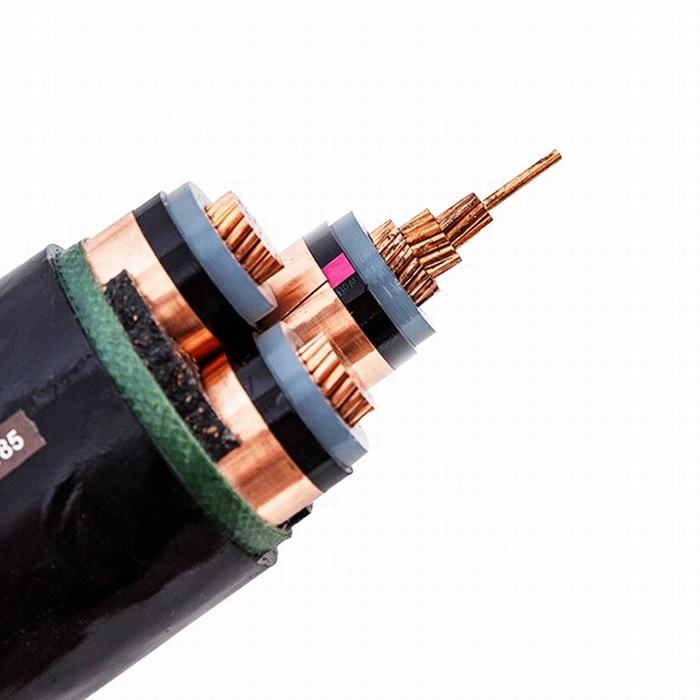

Construction:

| Conductor: | Cu, class 1 or 2 acc. to HRN HD 383 / IEC 60228 / DIN VDE 0295 | |

| class 1: | solid, round (RE) | |

| class 2: | multi wire stranded, round (RM) or sector (SM), multi wire exceeding 50 mm² are compacted | |

| Insulation: | PVC compound DIV-4 acc. to HRN HD 603.1, concentrically stranded cores, colour marked acc. to HRN HD 308 S2 / VDE 0293-308, without protective yellow-green conductor | |

| Filler: | spouted elastomer or plastomer compound or wrapped thermoplastic tapes | |

| Concentric conductor: | in inner layer corrugated spirally wrapped copper wires, in external layer copper tape wrapped in counter-helix | |

| Sheath: | PVC compound DMV-5 acc. to HRN HD 603.1 | |

| sheath colour: | black | |

Technical data:

| Temperature range: | |

| during installation: | -5 °C up to +50 °C |

| fixed installed: | -30 °C up to +70 °C |

| at short circuit of max. 5 s: | up to 160 °C |

| Nominal voltage: | Uο/U = 0,6/1 kV |

| Test voltage: | 4 kV |

| Max. operating voltage in three-phase systems: | 1,2 kV |

| Maximal tensile strength: | 50 N/mm² |

| Behaviour in fire: | IEC 60332-1 |

| Minimal inner bending radius: | |

| single core: | 15D |

| multi core: | 12D |

Dimensions:

| number of cores x conductor cross-section | Construction | Construction of individual conductor | External diameter | Insulation thickness | Sheath thickness | Conductor resistance at 20 °C | Short circuit current 1s | Cable weight |

| nominal | min-max. | nominal | nominal | max. | nom. | prib. | ||

| N x mm² | n x mm | mm | mm | mm | Ω/km | kA | kg/km | |

| 2 x 10/10 | RE | 1 x 3,56 | 19 – 22 | 1,0 | 1,8 | 1,83 | 1,15 | 610 |

| 2 x 16/16 | RE | 1 x 4,51 | 20 – 23 | 1,0 | 1,8 | 1,15 | 1,84 | 840 |

| 3 x 10/10 | RE | 1 x 3,56 | 18 – 22 | 1,0 | 1,8 | 1,83 | 1,15 | 750 |

| 3 x 16/16 | RE | 1 x 4,51 | 20 – 24 | 1,0 | 1,8 | 1,15 | 1,84 | 1050 |

| 3 x 25/16 | RM | 7 x 2,13 | 25 – 31 | 1,2 | 1,8 | 0,73 | 2,87 | 1600 |

| 3 x 25/25 | RM | 7 x 2,13 | 25 – 31 | 1,2 | 1,8 | 0,73 | 2,87 | 1600 |

| 3 x 35/16 | SM | 7 x 2,52 | 25 – 31 | 1,2 | 1,8 | 0,54 | 4,02 | 1700 |

| 3 x 35/35 | SM | 7 x 2,52 | 25 – 31 | 1,2 | 1,8 | 0,54 | 4,02 | 1850 |

| 3 x 50/25 | SM | 19 x 1,83 | 26 – 33 | 1,4 | 1,9 | 0,39 | 5,75 | 2300 |

| 3 x 50/50 | SM | 19 x 1,83 | 26 – 33 | 1,4 | 1,8 | 0,39 | 5,75 | 2400 |

| 3 x 70/35 | SM | 19 x 2,17 | 30 – 37 | 1,4 | 2,0 | 0,27 | 8,05 | 2900 |

| 3 x 70/70 | SM | 19 x 2,17 | 31 – 38 | 1,4 | 2,0 | 0,27 | 8,05 | 3300 |

| 3 x 95/50 | SM | 19 x 2,52 | 35 – 42 | 1,6 | 2,2 | 0,19 | 10,9 | 4000 |

| 3 x 95/95 | SM | 19 x 2,52 | 37 – 44 | 1,6 | 2,2 | 0,19 | 10,9 | 4500 |

| 3 x 120/70 | SM | 37 x 2,03 | 38 – 45 | 1,6 | 2,3 | 0,15 | 13,8 | 5000 |

| 3 x 120/120 | SM | 37 x 2,03 | 38 – 45 | 1,6 | 2,3 | 0,15 | 13,8 | 5500 |

| 3 x 150/70 | SM | 37 x 2,27 | 42 – 49 | 1,8 | 2,4 | 0,12 | 17,2 | 6000 |

| 3 x 150/150 | SM | 37 x 2,27 | 43 – 50 | 1,8 | 2,4 | 0,12 | 17,2 | 6750 |

| 3 x 185/95 | SM | 37 x 2,52 | 47 – 54 | 2,0 | 2,6 | 0,10 | 21,3 | 7500 |

| 3 x 240/120 | SM | 61 x 2,24 | 52 – 59 | 2,2 | 2,8 | 0,08 | 27,6 | 10000 |

| 4 x 10/10 | RE | 1 x 3,56 | 19 – 23 | 1,0 | 1,8 | 1,83 | 1,15 | 870 |

| 4 x 16/16 | RE | 1 x 4,51 | 21 – 25 | 1,0 | 1,8 | 1,15 | 1,84 | 1250 |

| 4 x 25/16 | RM | 7 x 2,13 | 25 – 32 | 1,2 | 1,8 | 0,73 | 2,87 | 1800 |

| 4 x 35/16 | SM | 7 x 2,52 | 26 – 33 | 1,2 | 1,8 | 0,54 | 4,02 | 2050 |

| 4 x 50/25 | SM | 19 x 1,83 | 29 – 36 | 1,4 | 2,0 | 0,39 | 5,75 | 2700 |

| 4 x 70/35 | SM | 19 x 2,17 | 34 – 41 | 1,4 | 2,1 | 0,27 | 8,05 | 3750 |

| 4 x 95/50 | SM | 19 x 2,52 | 34 – 41 | 1,6 | 2,3 | 0,19 | 10,9 | 5000 |

| 4 x 120/70 | SM | 37 x 2,03 | 43 – 50 | 1,6 | 2,4 | 0,15 | 13,8 | 6300 |

| 4 x 150/70 | SM | 37 x 2,27 | 47 – 54 | 1,8 | 2,6 | 0,12 | 17,2 | 7600 |

| 4 x 185/95 | SM | 37 x 2,52 | 55 – 62 | 2,0 | 2,7 | 0,10 | 21,3 | 9300 |

| 4 x 240/120 | SM | 61 x 2,24 | 62 – 70 | 2,2 | 2,9 | 0,08 | 27,6 | 11600 |

*) Packing: CUT = cable in different lengths on drum or reel, possible cutting at required length.

For more information and inquiry, pls contact me without any hesitation.

- Next: Price 24 Core 48 Core Optical Fiber Opgw Cable

- Previous: 0.6/1kv 4X120+70mm2 Copper PVC/PVC Sta Power Cable