Safe Listing

Product Description

(1) Safety signs should be set up in obvious places related to safety, and people should have enough time to pay attention to what they indicate.

(2) The safety signs set up at a specific location should be firmly installed to ensure that they will not cause danger. All signs should have a solid structure.

(3) When a safety sign is placed on a wall or other existing structure, the background color should form a contrasting color with the main color on the sign.

(4) The safety signs whose displayed information is no longer useful should be removed from the place of installation immediately. This is especially important for signs that warn of special temporary dangers, otherwise it will cause observers to ignore and interfere with other useful signs.

(5) When multiple signs are set together, they should be arranged in the order of warning, prohibition, instruction, and prompt type, first from left to right, and from top to bottom.

Installation location of safety signs

(1) Prevent the occurrence of hazardous accidents. The first thing to consider: the installation position of all signs must not be harmful to people.

(2) Visibility, the choice of sign installation location is very important, the information displayed on the sign must not only be correct, but also be clear and easy to read for all observers.

(3) Installation height. Usually the sign should be installed at a position slightly higher than the observer’s horizontal line of sight, but in some cases it is appropriate to place it in other horizontal positions.

(4) Danger and warning signs. Danger and warning signs should be set far enough in front of the source of danger to ensure that observers have sufficient time to see the signs and notice the danger for the first time. This distance varies with different situations. For example, signs warning not to touch switches or other electrical equipment should be placed near them, and signs on large factories or transportation roads should be placed far enough in front of the dangerous area to ensure that they can be observed before reaching the dangerous area To this kind of warning, be prepared.

(5) Safety signs should not be placed on moving objects, such as doors, because any change in the position of the object will cause the observation of the signs to become blurred.

(6) The installed sign should not be moved arbitrarily, unless the position change is beneficial to the warning effect of the sign.

3. Use of safety signs

(1) Danger signs are only installed in places where there is direct danger to indicate the existence of danger.

(2) Prohibition signs Use symbols or text descriptions to indicate a mandatory order to prohibit certain behaviors.

(3) Warning signs Use symbols or words to indicate danger, indicating that you must be careful, or to describe the attributes of danger.

(4) Safety indication signs are used to indicate the location of safety facilities and safety services, and the main safety instructions and suggestions related to safety measures are given here.

(5) Fire-fighting signs are used to indicate the location of fire-fighting facilities and fire alarms, and how to use these facilities.

(6) Direction signs are used to indicate the direction of normal and emergency exits, fire escape and safety facilities, safety services and toilets.

(7) Traffic signs are used to indicate instructions and warnings related to traffic safety to the staff.

(8) Information signs are used to indicate information with special attributes, such as parking lots, warehouses or telephone rooms.

(9) Mandatory action signs are used to indicate the order to perform a certain behavior and the preventive measures that need to be taken. For example, wear protective shoes, hard hats, goggles, etc.

Maintenance and management of safety signs

In order to effectively play the role of the sign, it should be checked regularly and cleaned regularly. When any deformation, damage, discoloration, falling off of graphic symbols, aging of brightness and other phenomena are found, it should be replaced or repaired immediately to keep it in good condition. The safety management department shall do a good job of supervision and inspection, find problems and correct them in time.

In addition, it is necessary to regularly publicize the procedures for the use of safety signs to the staff, especially those who need to observe preventive measures. When it is recommended to set up a new sign or change the position of an existing sign, the staff should be notified in advance and explain its setting or change The reason for this, so that employees know that only when these issues are comprehensively considered, can the safety signs set up be able to effectively play the role of safety warnings.

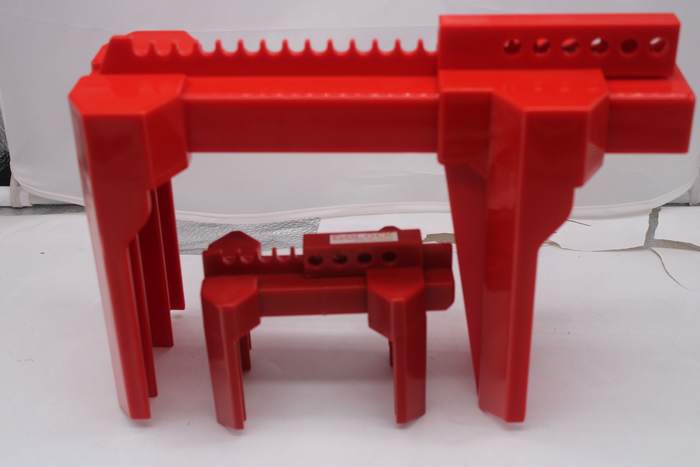

Safety padlocks are a kind of safety locks. Safety locks are usually divided into safety padlocks, electrical switch locks, electrical plug locks, circuit breaker locks, valve locks and cable locks, etc. Usually safety padlocks are used together with other safety locks. Safety padlocks can be used alone, but other safety locks cannot. Therefore, safety padlocks are widely used and the market demand is also very large.

Three-level security padlock

padlock

lock

Lightning protection padlock

Anti-static padlock

Buckle lock

The appearance of the safety padlock is similar to the ordinary civilian padlock, but there are many differences between the safety padlock and the ordinary civilian padlock.

Safety padlocks are generally made of ABS engineering plastics, while civil padlocks are generally made of metal;

The main purpose of safety padlocks is to warn and not to prevent theft, and the main purpose of ordinary civilian padlocks is to prevent theft;

The lock beam of the safety padlock cannot be opened automatically and has the function of retaining the key, while the ordinary civilian padlock is just the opposite;

Ordinary civilian padlocks are generally a lock with a key, while safety padlocks can be equipped with multiple keys, which are divided into management locks and ordinary locks;

Safety padlocks are often exposed to acid and alkali environments and require special treatment, while ordinary civilian padlocks are usually not used.

- Next: Lock

- Previous: Insulation Piercing Clamp