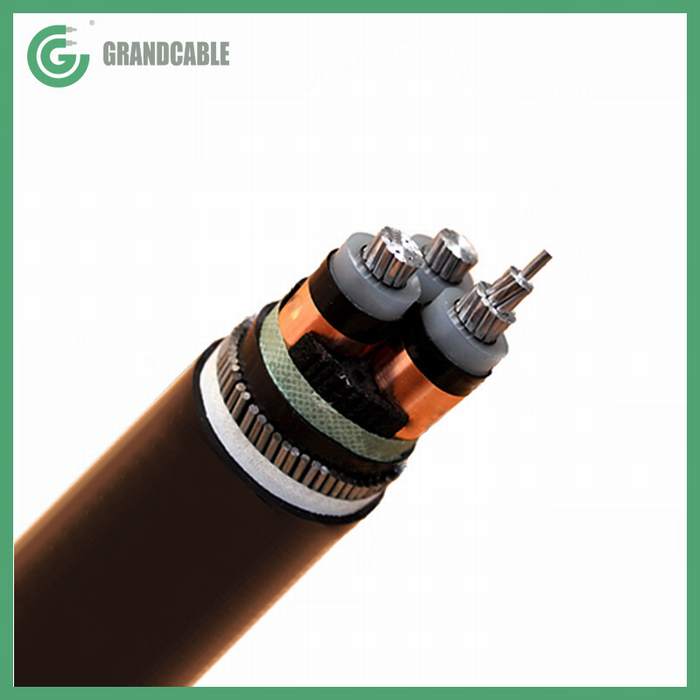

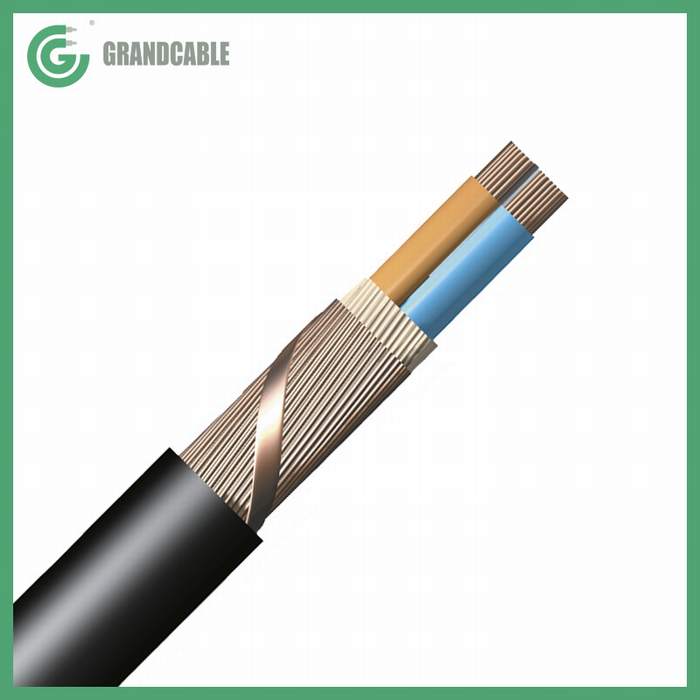

Low Voltage LV Copper XLPE Insulated PVC Sheathed Electric Power Cable

Product Description

1.Product Description

0.6/1KV,1.8/1KV,3.6/6KV,6/10K,8.7/15KV,12/20KV,18/30KV,26/35KV XLPE insulated power cable

(1)Production capacity:5000km/month

(2)MOQ:1km

(3)Delivery:5~15 officail days.

(4)Standards:IEC,ASTM,DIN,BS; or according to customers’ requirements.

2.Specification

1.) Conductors: copper or aluminum.

2.)Both armored and non-armored type power cables are available.

3.)Voltage rating: 0.6/1kV 3.6/6kV 6/10kV 8.7/15kV 26/35kV.

4.)PVC or XLPE sheathed.

5.)Number of cable cores: one core (Single core),two cores(Double cores),three cores, four cores (Four Equal-section-area cores or three equal-section area cores and one smaller section area neutral core), five cores (Five equal area cores or three equal-section-area cores and two smaller section area neutral cores).

6.)Standards: IEC 60502.IEC, BS, DIN, ASTM, CSA, NFC, AS, GOST etc. Or other special characteristics as customers request.

3.Characteristics of Cable

1.)Max Long-time operating temperature of PVC insulated cable is 70°C,XLPE 90°C

2.)Installing temperature of cable should not be less than 0°C

3.)Max short-circuit temperature is:PVC not exceed 160°C,XLPE 250°C,Not more than5 Sec.

4.)Permitting bending radius cable: Not less than 10 D times (D:external diameter of cable)

5.)Perfect chemical stability, resistant against acids, alkali, grease and organic solvents, and flamer retardant.

Number of Cores & Nominal Cross-section Area

| Number of Cores | 1 | 2 | 3 | 3+1 | 4 | 3+2 | 4+1 | 5 |

| Section Area (mm2) | 4 – 500 | 2.5 – 500 | 2.5 – 300 | 4 – 300 | 2.5 – 300 | 2.5 -300 | 4 – 300 | 2.5 – 95 |

4.Installation:

1. )The installation temperature should not over 20ºC, If the ambient temperature is lower than 0ºC, the cable should be preheated.

2.) The bending radius of cable should not less than 8 times.

3. )After installantion, the cable should with stand voltage test for 15min. 3.5kv D.C.

5.In air:

1.) As the single core cable laying in parallel, the distance between the cable’s center is 2 times (for cables which cross section area of conductor ≤185mm2) and

90mm (for cables which cross sectional area of conductor≥240mm2)

2.) Ambient temperature: 30ºC

3.) Max. temperature of conductor: 70ºC

4.)Rating factors of current rating for ambient temperature:

| Air temperature | 20ºC | 25ºC | 35ºC | 40ºC | 45ºC |

| Rating factors | 1.12 | 1.06 | 0.94 | 0.87 | 0.79 |

6.Direct in ground:

1.) When the single core cables are installed separately, the distance between the cable’s center is 2 times of the cable diameter.

2.) Ambient temperature: 25ºC.

3.) Max. temperature of conductor: 70ºC.

4.) Soil thermour resistivity: 1.0ºC. m/w.

5. ) Depth: 0.7m

6. ) Rating factors under different ambient temp.:

| Air temperature | 15ºC | 20ºC | 30ºC | 35ºC |

| Rating factors | 1.11 | 1.05 | 0.94 | 0.88 |

7. Paramater of 3+E core Xlpe or PVC Insulation Electric Power Cable

|

Cable size |

Conductor type | Nominal thickness of PVC insulation(mm) | Approx. diameter of steel wire(mm) |

Nominal thickness of PVC sheath (mm) |

Approx. cable overall diameter (mm) |

Max. D.C resistance @ 20 0 C (Ω/km) | |||

| Phase core |

Earth core |

Phase core |

Earth core |

Phase core |

Earth core |

||||

| 3×2.5+1.5mm 2 | RE | RE | 0.8 | 0.8 | 1.25 | 1.8 | 16.1 | 7.41 | 12.1 |

| 3×4+2.5mm 2 | RE | RE | 1.0 | 0.8 | 1.25 | 1.8 | 18.3 | 4.61 | 7.41 |

| 3×6+4mm 2 | RE | RE | 1.0 | 1.0 | 1.25 | 1.8 | 19.8 | 3.08 | 4.61 |

| 3×10+6mm 2 | RM | RE | 1.0 | 1.0 | 1.6 | 1.8 | 23.5 | 1.83 | 3.08 |

| 3×16+10mm 2 | RM | RM | 1.0 | 1.0 | 1.6 | 1.8 | 26.2 | 1.15 | 1.83 |

| 3×25+16mm 2 | SM | RM | 1.2 | 1.0 | 1.6 | 1.8 | 28.0 | 0.727 | 1.15 |

| 3×35+16mm 2 | SM | RM | 1.2 | 1.0 | 1.6 | 1.8 | 29.6 | 0.524 | 1.15 |

| 3×50+25mm 2 | SM | SM | 1.4 | 1.2 | 1.6 | 2.0 | 32.8 | 0.387 | 0.727 |

| 3×70+35mm 2 | SM | SM | 1.4 | 1.2 | 2.0 | 2.1 | 37.4 | 0.268 | 0.524 |

| 3×95+50mm 2 | SM | SM | 1.6 | 1.4 | 2.0 | 2.3 | 41.7 | 0.193 | 0.387 |

| 3×120+70mm 2 | SM | SM | 1.6 | 1.4 | 2.5 | 2.4 | 46.2 | 0.153 | 0.268 |

| 3×150+70mm 2 | SM | SM | 1.8 | 1.4 | 2.5 | 2.5 | 49.6 | 0.124 | 0.268 |

| 3×185+95mm 2 | SM | SM | 2.0 | 1.6 | 2.5 | 2.7 | 54.5 | 0.0991 | 0.193 |

| 3×240+120mm 2 | SM | SM | 2.2 | 1.6 | 2.5 | 2.9 | 60.3 | 0.0754 | 0.153 |

| 3×300+150mm 2 | SM | SM | 2.4 | 1.8 | 2.5 | 3.1 | 65.9 | 0.0601 | 0.124 |

| 3×400+185mm 2 | SM | SM | 2.6 | 2.0 | 3.15 | 3.5 | 74.1 | 0.0470 | 0.0991 |

8.Our Services

We can design and manufacture many kinds of electrical wires and cables in accord with different standard,such as ASTM ,IEC,BS,DIN, CSA,NF,AS/NZS etc.;

Our main products are as follows:

1)Bare Conductor and wire ,such as AAC,AAAC,ACSR,ACAR,AACSR,ACSR/AW , GSW, and so on;

2)Aerial Bundled Cable (1kV-35kV ),such as Duplex,Triplex,Quadruplex Drop Wires and so on;

3)PVC Insulated (Flexible ) Wire ;

4) PVC Insulated and Sheathed (Armoured) Power Cable;

5)Low, Medium, High Voltage (1kV-220kV) XLPE Insulated (Armoured) Power Cable;

6)Welding Cable, Control Cable, Concentric Cable, Coaxial, Rubber Sheathed Cable and so on;

Our products have been widely supplied to power utilities, electrical materials distributors and dealers, construction and engineering firms, electrical contractors or industrial companies all over the world, such as South America,Central America,North America,Europe,Australia,Middle East, South-East Asia, Africa and so on. Welcome your OEM and ODM orders.

- Next: Zr-Kvvrp Control Cable and Flexible Control Cable

- Previous: 450/750V IEC60245 Standard 95mm2 Copper PVC Insulation Electric Welding Cable

Contact us

Similar Or Related

-

15kV 3 Core 4/0AWG Aluminum Conductor XLPE Insulated SWA Armored MV Power Cable

-

XLPE Insulated Aerial Service Drop Cable Conductor #3AWG Duplex ICEA S-66-524 NEMA WC7

-

3Cx185mm2 XLPE Insulated Copper Tape Screened Galvanized Steel Wire Armored Power Cable 33kV

-

0.6/1kV 4Cx500mm2 Copper Conductor PVC Insulated SWA Armored LV Power Cable IEC 60502-1

-

Low Voltage Single Core Power Cable 1X300 mm2 N2XCH CU/XLPE/CWS/LSF 0.6/1kV

-

Low Voltage LV Copper XLPE Insulated PVC Sheathed Electric Power Cable