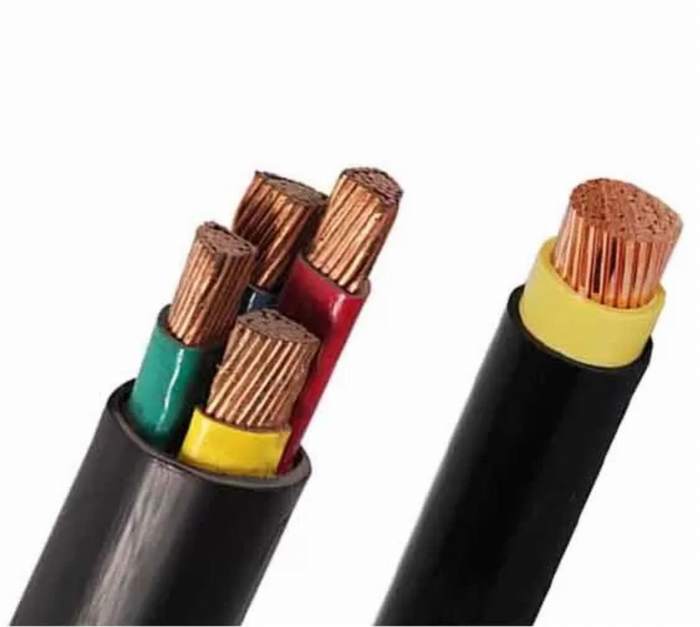

Copper Conductor PVC Insulated Power Cable

Product Description

Application:

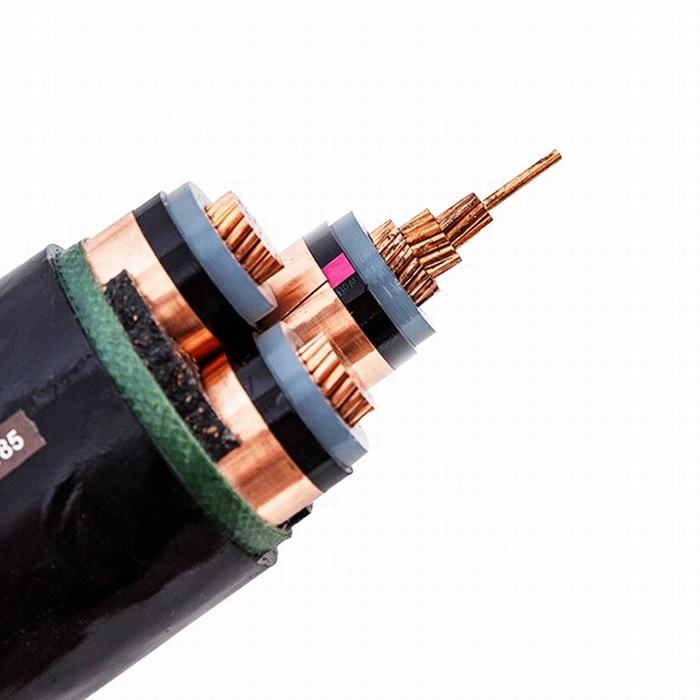

It is used to transmit and distribute power in power transmission and distribution system of 35kV or lower. It is generally applied to the fields including power, construction, mines, metallurgy, petrochemical industry and communication in complete replace of oil immersed paper insulated power cable and in partial replace of PVC insulated power cable.

Using features:

1. Rated voltage: Uo/U: 26/35kV, 21/35kV, 12/20 kV (24 kV), 8.7/10kV, 8.7/15kV, 6/6kV, 6/10kV and 0.6/1kV.

2. No. Of core: Single-core, Two-core, Three-core, Four-core, Five-core, Six-core.

3. The highest allowed operating temperature of conductor for long-term working is 90oC. In short-circuit (Max. Long-term is no more than 5 seconds). The highest temperature for conductor is no more than 250 degree.

4. D. C. Resistance of the conductor complies with the stipulations of international standar.

5. The environment temperature should be no lower than zero degree when lay. Otherwise it should be preheated.

6. The cable is laid without horizontal drop limit. The Min. Bending radius of cables should be no smaller than 12 times of cable outer diameter.

7. Working Frequency Voltage Test:

For cable with Uo of 3.6kV or lower: 2.5Uo+2kV/5min without puncture.

For cable with Uo of 3.6Kv~18kV: 3.5Uo/5min without puncture.

For cable with Uo of 21kV and 26 kV: 2.5Uo/30min without puncture.

8. Partial Discharge Test: The discharge volume should be no more than 10PC under 1.73Uo for the cable

Packing: Export wooden drums

| 1)3.6/6(7.2)kV,3.6/6.6(7.2)kV,Three Cores,Al or Cu/XLPE/CTS/STA/PVC Armoured Power Cable | |||||||||

| No.X Nominal Cross Section of Conductor | Nominal Diameter of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Copper Tape Screen | Nominal Thickness of Inner Sheath | Nominal Thickness of Steel Tape Armouring | Nominal Thickness of PVC Sheath | Approx. Overall Diameter | Approx. Weight | |

| Al Conductor | Cu Conductor | ||||||||

| No. X mm 2 | mm | mm | mm | mm | mm | mm | mm | kg/m | kg/m |

| 3 X 25 | 6 | 2.5 | 0.1 | 1.2 | 0.2 | 1.9 | 37.9 | 1.87 | 2.32 |

| 3 X 35 | 6.9 | 2.5 | 0.1 | 1.3 | 0.5 | 2 | 41.5 | 2.1 | 2.73 |

| 3 X50 | 8.2 | 2.5 | 0.1 | 1.3 | 0.5 | 2 | 44.3 | 2.37 | 3.22 |

| 3 X 70 | 9.7 | 2.5 | 0.1 | 1.4 | 0.5 | 2.1 | 47.9 | 2.77 | 4 |

| 3 X 95 | 11.3 | 2.5 | 0.1 | 1.4 | 0.5 | 2.2 | 51.6 | 3.21 | 4.91 |

| 3 X 120 | 12.8 | 2.5 | 0.1 | 1.5 | 0.5 | 2.4 | 55.4 | 3.69 | 5.84 |

| 3 X 150 | 14.2 | 2.5 | 0.1 | 1.5 | 0.5 | 2.5 | 58.6 | 4.15 | 6.85 |

| 3 X 185 | 15.9 | 2.5 | 0.1 | 1.5 | 0.5 | 2.6 | 62.5 | 4.73 | 8.11 |

| 3 X 240 | 18.3 | 2.6 | 0.1 | 1.6 | 0.5 | 2.7 | 68.5 | 5.62 | 10.05 |

| 3 X 300 | 20.4 | 2.8 | 0.1 | 1.7 | 0.5 | 2.9 | 74.5 | 6.55 | 12.11 |

| 3 X 400 | 23.2 | 3 | 0.1 | 1.9 | 0.8 | 3.2 | 83.6 | 8.78 | 15.86 |

| 3 X 500 | 26.4 | 3.2 | 0.1 | 2.1 | 0.8 | 3.4 | 93 | 10.52 | 18.85 |

| 2)6/10(12)kV,6.35/11(12)kV,,Three Cores,Al or Cu/XLPE/CTS/STA/PVC Armoured Power Cable | |||||||||

| No.X Nominal Cross Section of Conductor | Nominal Diameter of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Copper Tape Screen | Nominal Thickness of Inner Sheath | Nominal Thickness of Steel Tape Armouring | Nominal Thickness of PVC Sheath | Approx. Overall Diameter | Approx. Weight | |

| Al Conductor | Cu Conductor | ||||||||

| No. X mm 2 | mm | mm | mm | mm | mm | mm | mm | kg/m | kg/m |

| 3 X 25 | 6 | 3.4 | 0.1 | 1.3 | 0.5 | 2 | 43.4 | 2.16 | 2.61 |

| 3 X 35 | 6.9 | 3.4 | 0.1 | 1.3 | 0.5 | 2 | 45.4 | 2.36 | 2.99 |

| 3 X50 | 8.2 | 3.4 | 0.1 | 1.4 | 0.5 | 2.2 | 48.8 | 2.69 | 3.54 |

| 3 X 70 | 9.7 | 3.4 | 0.1 | 1.5 | 0.5 | 2.3 | 52.4 | 3.1 | 4.33 |

| 3 X 95 | 11.3 | 3.4 | 0.1 | 1.5 | 0.5 | 2.4 | 56.1 | 3.56 | 5.26 |

| 3 X 120 | 12.8 | 3.4 | 0.1 | 1.5 | 0.5 | 2.5 | 59.5 | 4.04 | 6.19 |

| 3 X 150 | 14.2 | 3.4 | 0.1 | 1.5 | 0.5 | 2.6 | 62.7 | 4.49 | 7.19 |

| 3 X 185 | 15.9 | 3.4 | 0.1 | 1.6 | 0.5 | 2.6 | 66.6 | 5.12 | 8.49 |

| 3 X 240 | 18.3 | 3.4 | 0.1 | 1.7 | 0.5 | 2.8 | 72.4 | 5.99 | 10.42 |

| 3 X 300 | 20.4 | 3.4 | 0.1 | 1.8 | 0.5 | 3 | 77.5 | 6.86 | 12.42 |

| 3 X 400 | 23.2 | 3.4 | 0.1 | 1.9 | 0.8 | 3.2 | 85.4 | 8.97 | 16.05 |

| 3 X 500 | 26.4 | 3.4 | 0.1 | 2 | 0.8 | 3.4 | 93.7 | 10.65 | 19.5 |

| 3)8.7/10(15)kV,Three Cores,Al or Cu/XLPE/CTS/STA/PVC Armoured Power Cable | |||||||||

| No.X Nominal Cross Section of Conductor | Nominal Diameter of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Copper Tape Screen | Nominal Thickness of Inner Sheath | Nominal Thickness of Steel Tape Armouring | Nominal Thickness of PVC Sheath | Approx. Overall Diameter | Approx. Weight | |

| Al Conductor | Cu Conductor | ||||||||

| No. X mm 2 | mm | mm | mm | mm | mm | mm | mm | kg/m | kg/m |

| 3 X 25 | 6 | 4.5 | 0.1 | 1.4 | 0.5 | 2.1 | 48.6 | 2.53 | 2.98 |

| 3 X 35 | 6.9 | 4.5 | 0.1 | 1.4 | 0.5 | 2.2 | 50.7 | 2.76 | 3.39 |

| 3 X50 | 8.2 | 4.5 | 0.1 | 1.5 | 0.5 | 2.3 | 53.9 | 3.1 | 3.95 |

| 3 X 70 | 9.7 | 4.5 | 0.1 | 1.5 | 0.5 | 2.4 | 57.4 | 3.51 | 4.74 |

| 3 X 95 | 11.3 | 4.5 | 0.1 | 1.5 | 0.5 | 2.6 | 61.2 | 4.05 | 5.75 |

| 3 X 120 | 12.8 | 4.5 | 0.1 | 1.6 | 0.5 | 2.6 | 64.7 | 4.56 | 6.72 |

| 3 X 150 | 14.2 | 4.5 | 0.1 | 1.6 | 0.5 | 2.7 | 67.9 | 5.04 | 7.74 |

| 3 X 185 | 15.9 | 4.5 | 0.1 | 1.7 | 0.5 | 2.8 | 71.9 | 5.66 | 9.04 |

| 3 X 240 | 18.3 | 4.5 | 0.1 | 1.8 | 0.5 | 3 | 77.7 | 6.56 | 11 |

| 3 X 300 | 20.4 | 4.5 | 0.1 | 1.9 | 0.8 | 3.2 | 84.1 | 8.39 | 13.96 |

| 3 X 400 | 23.2 | 4.5 | 0.1 | 2 | 0.8 | 3.3 | 90.5 | 9.71 | 16.79 |

| 3 X 500 | 26.4 | 4.5 | 0.1 | 2.1 | 0.8 | 3.5 | 98.8 | 11.45 | 20.57 |

| 4)12/20(24)kV, 12.7/22(24)kV,Three Cores,Al or Cu/XLPE/CTS/STA/PVC Armoured Power Cable | |||||||||

| No.X Nominal Cross Section of Conductor | Nominal Diameter of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Copper Tape Screen | Nominal Thickness of Inner Sheath | Nominal Thickness of Steel Tape Armouring | Nominal Thickness of PVC Sheath | Approx. Overall Diameter | Approx. Weight | |

| Al Conductor | Cu Conductor | ||||||||

| No. X mm 2 | mm | mm | mm | mm | mm | mm | mm | kg/m | kg/m |

| 3 X 25 | |||||||||

| 3 X 35 | 6.9 | 5.5 | 0.1 | 1.5 | 0.5 | 2.4 | 55.6 | 3.14 | 3.77 |

| 3 X50 | 8.2 | 5.5 | 0.1 | 1.5 | 0.5 | 2.5 | 58.6 | 3.49 | 4.34 |

| 3 X 70 | 9.7 | 5.5 | 0.1 | 1.5 | 0.5 | 2.6 | 62.1 | 3.93 | 5.16 |

| 3 X 95 | 11.3 | 5.5 | 0.1 | 1.6 | 0.5 | 2.6 | 65.7 | 4.46 | 6.16 |

| 3 X 120 | 12.8 | 5.5 | 0.1 | 1.7 | 0.5 | 2.7 | 69.4 | 5 | 7.15 |

| 3 X 150 | 14.2 | 5.5 | 0.1 | 1.7 | 0.5 | 2.8 | 72.6 | 5.49 | 8.19 |

| 3 X 185 | 15.9 | 5.5 | 0.1 | 1.8 | 0.5 | 3 | 76.9 | 6.16 | 9.53 |

| 3 X 240 | 18.3 | 5.5 | 0.1 | 1.9 | 0.8 | 3.2 | 83.9 | 7.87 | 12.31 |

| 3 X 300 | 20.4 | 5.5 | 0.1 | 2 | 0.8 | 3.2 | 88.6 | 8.96 | 14.52 |

| 3 X 400 | 23.2 | 5.5 | 0.1 | 2.1 | 0.8 | 3.5 | 95.4 | 10.35 | 17.43 |

| 3 X 500 | 26.4 | 5.5 | 0.1 | 2.2 | 0.8 | 3.7 | 103.7 | 12.45 | 20.23 |

| 5)18/30(36)kV,19/33(36)kV,Three Cores,Al or Cu/XLPE/CTS/STA/PVC Armoured Power Cable | |||||||||

| No.X Nominal Cross Section of Conductor | Nominal Diameter of Conductor | Nominal Thickness of Insulation | Nominal Thickness of Copper Tape Screen | Nominal Thickness of Inner Sheath | Nominal Thickness of Steel Tape Armouring | Nominal Thickness of PVC Sheath | Approx. Overall Diameter | Approx. Weight | |

| Al Conductor | Cu Conductor | ||||||||

| No. X mm 2 | mm | mm | mm | mm | mm | mm | mm | kg/m | kg/m |

| 3 X 25 | |||||||||

| 3 X 35 | |||||||||

| 3 X50 | 8.2 | 8 | 0.1 | 1.7 | 0.5 | 2.8 | 70.4 | 4.56 | 5.41 |

| 3 X 70 | 9.7 | 8 | 0.1 | 1.7 | 0.5 | 2.9 | 73.9 | 5.04 | 6.26 |

| 3 X 95 | 11.3 | 8 | 0.1 | 1.8 | 0.5 | 3 | 77.7 | 5.62 | 7.32 |

| 3 X 120 | 12.8 | 8 | 0.1 | 1.9 | 0.8 | 3.2 | 82.8 | 6.99 | 9.15 |

| 3 X 150 | 14.2 | 8 | 0.1 | 1.9 | 0.8 | 3.2 | 85.8 | 7.56 | 10.26 |

| 3 X 185 | 15.9 | 8 | 0.1 | 2 | 0.8 | 3.3 | 89.9 | 8.3 | 11.67 |

| 3 X 240 | 18.3 | 8 | 0.1 | 2.1 | 0.8 | 3.5 | 95.7 | 9.36 | 13.79 |

| 3 X 300 | 20.4 | 8 | 0.1 | 2.2 | 0.8 | 3.6 | 100.6 | 10.51 | 16.07 |

| 3 X 400 | 23.2 | 8 | 0.1 | 2.3 | 0.8 | 3.8 | 107.2 | 11.99 | 19.07 |

| 3 X 500 | 26.4 | 8 | 0.1 | 2.4 | 0.8 | 4 | 120.1 | 14.15 | 23.85 |

Workshop

Shipment

QA&QC

CUSTOMER VISIT

FAQ

1. How many years has Henan Jiapu Cable Group been in production?

Founded in October 1998 by Mr. Gu, our facility has three separate manufacturing workshops within its 100,000-sq.-ft. building. In 2012, we operates in a new 666,000 sq. foot state-of-the-art facility in Xiaodian Industry Park.,Xinxiang, Henan ,China

2. What kinds of products does Jiapu Cable manufacture?

1)Bare Conductor ,such as AAC,AAAC,ACSR,ACAR,AACSR,ACSR/AW and so on;

2)Aerial Bundled Cable (1kV-35kV ),such as Duplex,Triplex,Quadruplex Drop Wires and so on;

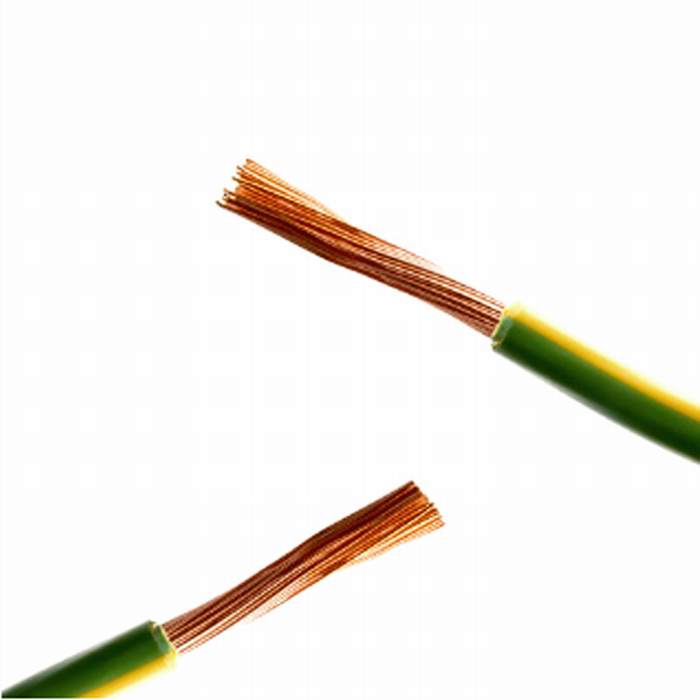

3)PVC Insulated (Flexible ) Wire ;

4) PVC Insulated and Sheathed (Armoured) Power Cable;

5)Low, Medium, High Voltage (1kV-220kV) XLPE Insulated (Armoured) Power Cable;

6)Welding Cable, Control Cable, Concentric Cable, Rubber Sheathed Cable and so on;

3. What kind of certifications do you have?

SABS, CE, ISO9001-2000, SGS

4.Which markets do you involve mainly in?

Our products have been exported mainly to Africa, Middle East, South-east Asia, South America,Central America,North America, Europe ,Australia, etc.

5. Which standards do you comply with when you produce the electrical wires and cables ?

We are able to produce electrical wires and cables based on GB, JB, IEC, BS, DIN, ASTM, JIS, NF, AS/NZS, CSA, etc. Meanwhile, we can design and manufacture the cables according to the samples and technical specification the customer supply.

6. What is the min.order quantity ?

It depends on the type and size of electrical wires and cables. For some small electrical wires, 100 meters can be accepted .But for the power cables with medium or high voltage, that should comply with the property of installed equipments. Anyhow,we will try our best to solve the problem and meet with the requirement If you have special request.

7. What is the production capacity per week or per month ?

For the bare conductor, we can finish 3000 tons within one month. For power cables, that depends on the type and size. The total output value per month is approx. USD3,000,000.00 for insulated aluminum cables and that is approx. USD8,000,000.00 for insulated copper cables.

8. Do you supply the customers with installation service in foreign country ?We don’t have professional installation teams in foreign country.But if that is necessary, we will recommend our partners to cooperate with you.

- Next: High Quality 50mm PVC Insulated Electric Cable, Power Cable

- Previous: Aluminium Conductor XLPE Insulated Overhead ABC Cable, Power Cable