Conductor De Al. Tipo AAAC De 120mm2 Cableado De 19 Hilos

Product Description

Packaging & Delivery

Packaging Details:

Robust Construction Seaworthy Heated Treated Wooden Drums/Pallets

1.Certificates of Qualification Offered.

2.Certificates of Origin Offered(Upon Customers’requests)

3.Certificate of Fumigation Offered(Upon Customers’requests)

Delivery Detail:

Less than 500meters, 1-3 days;500-10,000 and above,1-3 weeks

Specifications

conductors aaac best quality

1.Conform to IEC,BS,ASTM etc

2.Prompt Delivery, Direct Factory Price

3.Best Service

ACSR/AAAC Conductor detail

Specifications

AAAC Cable

1.Conform to IEC,BS,ASTM etc

2.Prompt Delivery, Direct Factory Price

3.Best Service

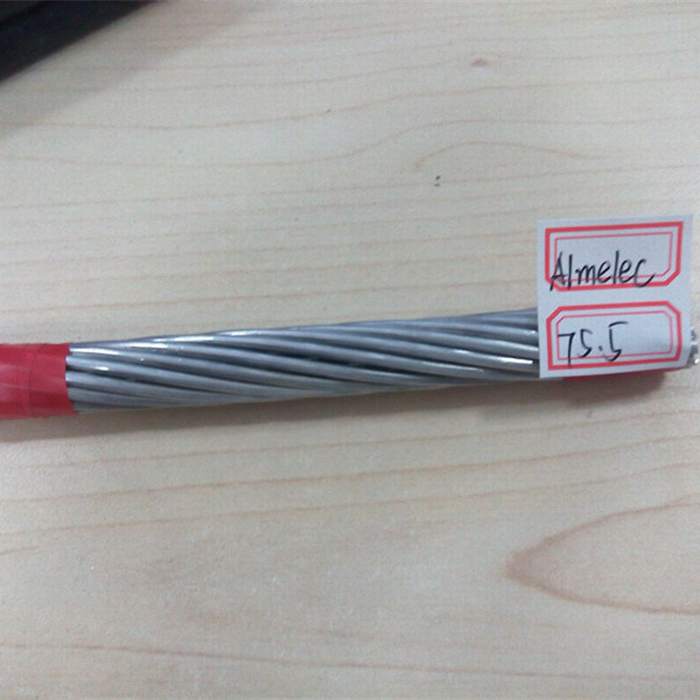

Bare Stranded All Aluminum Alloy Conductor/AAAC

Cable/AAAC Conductor

Introduction :

AAAC Conductor Cable have been widely used in power transmission lines with various voltage levels, and

also used in power lines across great rivers, heavy ice area, and other places special geographical characteristics.

The conductor have excellent advantages of high strength, large current carrying capacity and good catenary

and maintenance, low cost for the line, large transmission capacity.

Specifications:

Conductor(AAAC) bear conductor meets or exceeds the following ASTM Specifications:

B-398 Aluminum Alloy 6201-T81 Wire for Electrical Purpose.

B-399 Concentrical-Lay-Stranded 6201-T81 Aluminum Alloy Conductors.

The electrical performance of AAAC is indicated in DCΩ /km(20oC). The resistivity of aluminum

alloy wire for stranded wires is:

LHA1: not greater than 32.840nΩ . m

LHA2: not greater than 32.530nΩ . m

The rated tensile strength of AAAC is denoted with the result of total cross-section areas of all

aluminum alloy conductors multiplied by min. Tensile strength of corresponding size specified

in the standard for aluminum alloy wire.

Standard:

We can produce as per the standard of GB, IEC, ASTM,DIN,CSA,JIS and also particularly

customize and manufacture according to your special requirement.

Product details:

| Conductor size (mm2) |

Alloy area (mm2) |

Number of wires |

Overall diameter of conductor (mm) |

Linear mass (kg/km) |

Rated tensilestrength daN |

Maximum resistance D.C. at 20°C (Ω/km) |

| 16 | 15.89 | 7 | 5.1 | 43 | 444 | 2.091 |

| 25 | 24.25 | 7 | 6.3 | 66 | 677 | 1.3703 |

| 35 | 34.36 | 7 | 7.5 | 94 | 960 | 0.9669 |

| 50 | 49.48 | 7 | 9 | 135 | 1382 | 0.6714 |

| 50 | 48.35 | 19 | 9 | 133 | 1350 | 0.6905 |

| 70 | 65.81 | 19 | 10.5 | 181 | 1838 | 0.5073 |

| 95 | 93.27 | 19 | 12.5 | 256 | 2605 | 0.3579 |

| 120 | 116.99 | 19 | 14 | 322 | 3268 | 0.2854 |

| 150 | 147.11 | 37 | 15.8 | 406 | 4109 | 0.2274 |

| 185 | 181.62 | 37 | 17.5 | 500 | 5073 | 0.1842 |

| 240 | 242.54 | 61 | 20.3 | 670 | 6774 | 0.1383 |

| 300 | 299.43 | 61 | 22.5 | 827 | 8363 | 0.112 |

| 400 | 400.14 | 61 | 26 | 1104 | 11176 | 0.0838 |

| 500 | 499.63 | 61 | 29.1 | 1379 | 13960 | 0.0671 |

| 625 | 626.2 | 91 | 32.6 | 1732 | 17490 | 0.054 |

| 800 | 802.09 | 91 | 36.9 | 2218 | 22402 | 0.0418 |

| 1000 | 999.71 | 91 | 41.1 | 2767 | 27922 | 0.0335 |

| AAAC Conductor Technical Characteristics Based on Standard NFC 34-125 | |||||||

| Code number | Area | Number of wires |

Wire diameter |

Conductor diameter |

Linear mass | Rated strength | D.C. resistance at 20oC |

| mm2 | No. | mm | mm | kg/km | kN | Ω/km | |

| ASTER 54.6 | 54.6 | 7 | 3.15 | 9.45 | 148.9 | 17.73 | 0.6042 |

| ASTER 148 | 148.1 | 19 | 3.15 | 15.8 | 406.5 | 48.12 | 0.2239 |

| ASTER 228 | 227.8 | 37 | 2.8 | 19.6 | 627.6 | 74.04 | 0.146 |

| ASTER 288 | 288.3 | 37 | 3.15 | 22.1 | 794.3 | 93.71 | 0.1154 |

- Next: 6/6, 6/10kv 3*70 Cu/ Al Core XLPE Insulated Steel Wire Armored Power Cable

- Previous: Acar Aluminium Conductor Aluminium Alloy Reinforced with ASTM/IEC