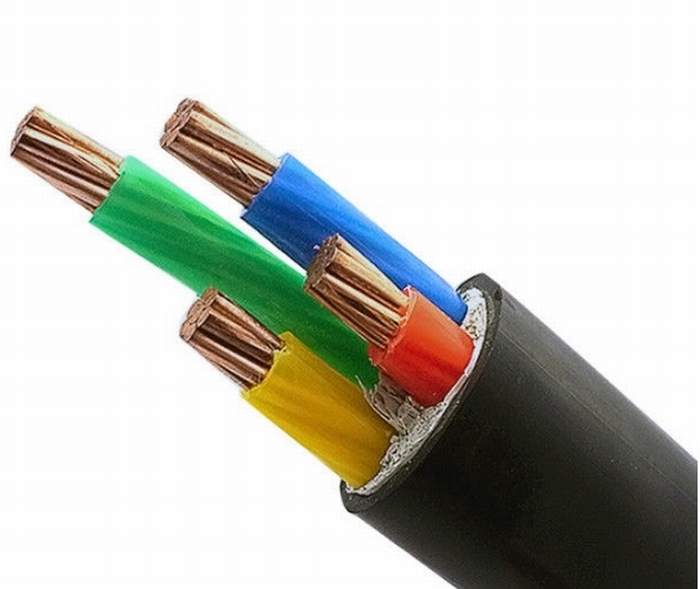

Al Core XLPE Insulated PVC Coated 3X150mm2 Power Cable

Product Description

1.XLPE/PVC Insulation LV (Low Voltage) Power Cable cable belongs to cables rated voltage up to 1KV. They are used for laying indoor, tunnel, underground, canal, water and seabed, etc .

Standard available such as ASTM , BS , DIN ,NFC , AS/NZS , CSA , IS , etc.

2.Brief Construction:

2.1 Number of Core : 1Core , 2Core,3Core , 4Core , 5Core , 3+1Core(3.5Core) , 3+2 Core , 4+1Core , etc.

2.2 Conductor material: Copper or Aluminum (Stranded Round /Stranded compacted round/stranded compacted sector)

2.3 Insulation Material: XLPE/PVC/PE/LSHF

2.4 Inner sheath (applicable if there is armour layer): PVC/PE

2.5 Armour layer (if required) :Galvanized steel wire / Steel Tape

2.6 Outer sheath : PVC/PE

3.The max. conductor long time permissible operating temperature is 70 degree for PVC Insulation and 90degreefor XLPE Insulation ; In short circuit, max. Temperature is 160 degree for PVC Sheath and 250degreefor PVC Sheath.

4.Packing : In roll / In wooden drum / In Iron-wooden drum / In steel drum.

5.Certificate: ISO , CE , SGS, SONCAP , BV , COC,ETC.

6.For other detailed information, pls contact us directly .

| Class 2 stranded conductors for single-core and multi-core cables | |||||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Nominal crosssectional area | Minimum number of wires in the conductor | Maximum resistance of conductor at 20ºC | |||||||

| Circular | Circular compacted | Shaped | Annealed copper conductor | Aluminium or aluminium alloy conductor | |||||

| Cu | Al | Cu | Al | Cu | Al | Plain wires | Metal-coated wires | ||

| mm2 | Ω/KM | Ω/KM | Ω/KM | ||||||

| 0.5 | 7 | 36 | 36.7 | ||||||

| 0.75 | 7 | 24.5 | 24.8 | ||||||

| 1 | 7 | 18.1 | 18.2 | ||||||

| 1.5 | 7 | 6 | 12.1 | 12.2 | |||||

| 2.5 | 7 | 6 | 7.41 | 7.58 | |||||

| 4 | 7 | 6 | 4.61 | 4.7 | |||||

| 6 | 7 | 6 | 3.08 | 3.11 | |||||

| 10 | 7 | 7 | 6 | 6 | 1.83 | 1.84 | 3.08 | ||

| 16 | 7 | 7 | 6 | 6 | 1.15 | 1.16 | 1.91 | ||

| 25 | 7 | 7 | 6 | 6 | 6 | 6 | 0.727 | 0.734 | 1.2 |

| 35 | 7 | 7 | 6 | 6 | 6 | 6 | 0.524 | 0.529 | 0.868 |

| 50 | 19 | 19 | 6 | 6 | 6 | 6 | 0.387 | 0.391 | 0.641 |

| 70 | 19 | 19 | 12 | 12 | 12 | 12 | 0.268 | 0.27 | 0.443 |

| 95 | 19 | 19 | 15 | 15 | 15 | 15 | 0.193 | 0.195 | 0.32 |

| 120 | 37 | 37 | 18 | 15 | 18 | 15 | 0.153 | 0.154 | 0.253 |

| 150 | 37 | 37 | 18 | 15 | 18 | 15 | 0.124 | 0.126 | 0.206 |

| 185 | 37 | 37 | 30 | 30 | 30 | 30 | 0.0991 | 0.1 | 0.164 |

| 240 | 37 | 37 | 34 | 30 | 34 | 30 | 0.0754 | 0.0762 | 0.125 |

| 300 | 61 | 61 | 34 | 30 | 34 | 30 | 0.0601 | 0.0607 | 0.1 |

| 400 | 61 | 61 | 53 | 53 | 53 | 53 | 0.047 | 0.0475 | 0.0778 |

| 500 | 61 | 61 | 53 | 53 | 53 | 53 | 0.0368 | 0.0369 | 0.0605 |

| 630 | 91 | 91 | 53 | 53 | 53 | 53 | 0.0283 | 0.0286 | 0.0469 |

| 800 | 91 | 91 | 53 | 53 | 0.0221 | 0.0224 | 0.0367 | ||

| 1000 | 91 | 91 | 53 | 53 | 0.0176 | 0.0177 | 0.0291 | ||

| 1200 | b | 0.0151 | 0.0151 | 0.0247 | |||||

| 1400a | 0.0129 | 0.0129 | 0.0212 | ||||||

| 1600 | 0.0113 | 0.0113 | 0.0186 | ||||||

| 1800a | 0.0101 | 0.0101 | 0.0165 | ||||||

| 2000 | 0.009 | 0.009 | 0.0149 | ||||||

| 2500 | 0.0072 | 0.0072 | 0.0127 | ||||||

| a.These sizes are non-preferred. Other non-preferred sizes are recognized for some specialized applications but are not within the scope of this standard. b.The minimum number of wires for these sizes is not specified. These sizes may be constructed from 4, 5 or 6 equal segments (Milliken). c.For stranded aluminium alloy conductors having the same nominal cross-sectional area as an aluminium conductor the resistance value should be agreed between the manufacturer and the purchaser. |

|||||||||

- Next: Fire Resistant 0.6/1kv Cu/XLPE/Swa/PVC Cable

- Previous: Copper Conductor Power Cable Directly Buried XLPE Insulated 0.6/1kv