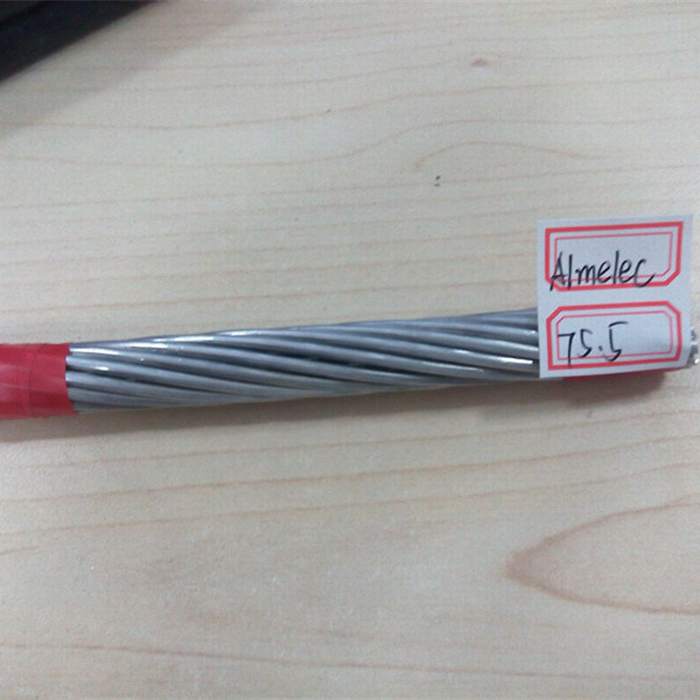

AAAC Conductor Aluminum Alloy Almelec Cable 34.4 mm2 54.6mm2 70mm2 117mm2

Product Description

AAAC –Aluminum Alloy Bare Conductor

Applications

Used as bare overhead conductor for primary and secondary distribution. Designed utilizing a high-strength aluminum alloy to achieve a high strength-to-weight ratio; affords better sag characteristics. Aluminum alloy gives AAAC higher resistance to corrosion than ACSR.

Construction

Standard 6201-T81 high strength aluminum conductors, conforming to ASTM Specification B-399, are concentric-lay- stranded, similar in construction and appearance to 1350 grade aluminum conductors. Standard 6201 alloy conductors are similar to other alloy conductors commercially known as Ardival, Aldrey or Almelec. They were developed to fill the need for an economical conductor for overhead applications requiring higher strength than that obtainable with 1350 grade aluminum conductors, but without a steel core. The DC resistance at 20°C of the 6201-T81 conductors and of the standard ACSRs of the same diameter are approximately the same. Conductors of the 6201-T81 alloys are harder and, therefore, have a greater resistance to abrasion than conductors of 1350-H19 grade aluminum.

Specifications

AAAC bare conductor meets or exceeds the following ASTM specifications :

B-398 Aluminum Alloy 6201-T81 Wire for Electrical Purposes

B-399 Concentric-Lay-Stranded 6201-T81 Aluminum Alloy Conductors

| AAAC Technical Characteristics Based on Standard BS 3242 | |||||||

| Code name | Nominal aluminium area | Stranding and wire diameter | Sectional area | Approx. overall diameter | Approx. mass | Calculated D.C. resistance at 20oC | Calculated breaking load |

| mm2 | No./mm | mm2 | mm | kg/km | Ω/km | kN | |

| OAK | 100 | 7/4.65 | 118.9 | 13.95 | 325 | 0.2769 | 33.3 |

| ASH | 150 | 19/3.48 | 180.7 | 17.4 | 497 | 0.183 | 50.65 |

| ELM | 175 | 19/3.76 | 211 | 18.8 | 580 | 0.1568 | 59.1 |

| UPAS | 300 | 37/3.53 | 362.1 | 24.71 | 997 | 0.09155 | 101.5 |

| AAAC Technical Characteristics Based on Standard DIN 48201 / DIN EN50182 | |||||||

| Code number | Area | Number of wires | Wire diameter | Conductor diameter | Linear mass | Rated strength | D.C. resistance at 20oC |

| mm2 | No. | mm | mm | kg/km | kN | Ω/km | |

| 35 | 34.4 | 7 | 2.5 | 7.5 | 93.8 | 10.14 | 0.9572 |

| 50 | 49.5 | 7 | 3 | 9 | 135.1 | 14.6 | 0.6647 |

| 70 | 65.8 | 19 | 2.1 | 10.5 | 180.7 | 19.41 | 0.5026 |

| 95 | 93.3 | 19 | 2.5 | 12.5 | 256 | 27.51 | 0.3546 |

| 120 | 117 | 19 | 2.8 | 14 | 321.2 | 34.51 | 0.2827 |

| 150 | 147.1 | 37 | 2.25 | 15.8 | 405.3 | 43.4 | 0.2256 |

| 240 | 242.5 | 61 | 2.25 | 20.3 | 670.3 | 71.55 | 0.1373 |

| 300 | 299.4 | 61 | 2.5 | 22.5 | 827.5 | 88.33 | 0.1112 |

ACSR & AAAC Conductor Wire (Aluminum Conduct Steel Reinforced) is widely used in the overhead power distribution system of our country.

Packing & Shipping

Why Choose Us ?

1. We have a large production base, and advanced production equipment

2. Have an competitive price and high quality

3. Excellent after-sale service

4. Free issue:packaging list,invoice

5. Powerful technology team

6. Strict quality assurance system and perfect testing means

7. Advanced process equipment

8. Delivery on time

9. Our cable sales to Middle East,Africa,Russia,Southeast Asia, etc.

10.We have a good reputation in the overseas

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock,

it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: 30% T/T in advance,70% T/T balance before shipment

If you have another question, pls feel free to contact us below

- Next: 3*4+1*6+2*12AWG Power Cable Al/XLPE/PVC Power Cable for Mexico

- Previous: Low Voltage Copper Cable 16mm 25mm 35mm 150mm 2 Core 3 Core 4 Core