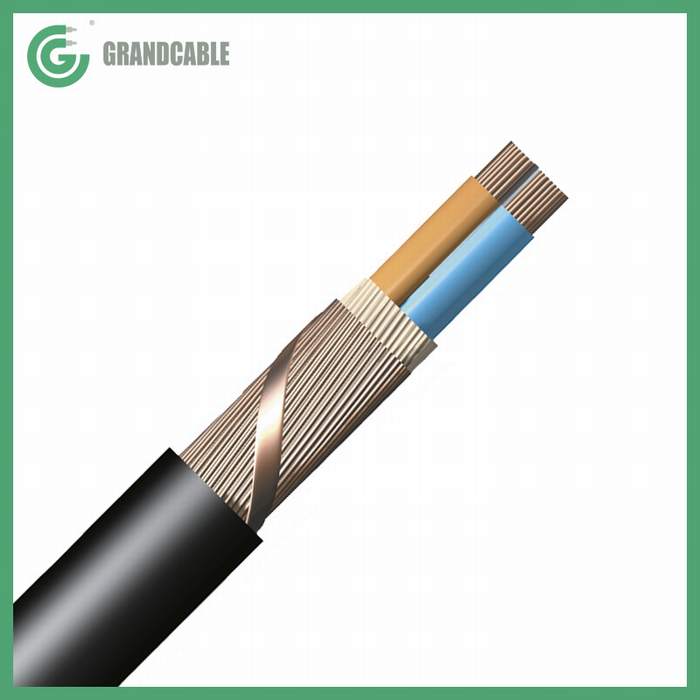

Dlo, Diesel Locomotive Cable, 2 Kv, 1/C, Cu/Epr/CPE (ICEA S-95-658/NEMA WC70/UL 44/CSA C22.2 No. 38)

Product Description

Features

Cable is Listed RHH/RHW-2 per UL, and Listed RW90/R90 per CSA. Jacket is rated Oil Resistance I or II rated per UL 44. All sizes meet VW-1 flame test. Type RHH/RHW-2 is rated Sun Resistance For CT use, 1/0 AWG and larger. Type RW90/R90 is rated -40 °C and FT4. Meets vertical flame tests.

Application

As power cable used in DLO Locomotive Cable, railroad and transit car wiring where high reliability is required. Also suitable for use in static and dynamic wind power applications. For portable and fixed installations leads for motors, generators, batteries.

Standards

UL 44

Rubber Insulated Wires and Cables.

CSA C22.2 No. 38

Thermoset Insulated Wires and Cables.

ICEA S-95-658/NEMA WC70

Nonshielded 0 – 2000 V Cables.

Specifications

Maximum operating voltage: 2000 volts

Maximum conductor operation temperatures: 90 °C wet and dry locations

Engineering Information

1. Conductor: Soft annealed tinned coated copper conductor, flexible stranding per AAR RP-588, and ASTM B3, B172, B174 as applicable. On request, uncoated copper wires.

Sizes: 14 AWG – 1111 kcmil.

2. Separator: A suitable opaque tape, as required.

3. Insulation: Flame retardant thermoset ethylene propylene rubber (EPR), meeting the requirements of UL 44.

4. Jacket: Black flame retardant thermoset chlorinated polyethylene (CPE) jacket, meeting the

requirements of UL 44.

| Conductor Size | Number of Strands | Size of Each Strand | Insulation Thickness | Jacket Thickness | Maximum Overall Diameter | Approximate Total Weight |

| AWG or kcmil | AWG | mil | mil | in | lb/kft | |

| 14 | 19 | 27 | 45 | 25 | 0.22 | 33.00 |

| 12 | 19 | 25 | 45 | 30 | 0.25 | 46.00 |

| 10 | 27 | 24 | 45 | 30.00 | 0.28 | 65.00 |

| 8 | 37 | 24 | 60 | 30 | 0.33 | 91.00 |

| 6 | 63 | 24 | 60 | 30 | 0.39 | 136.00 |

| 4 | 105 | 24 | 60 | 30 | 0.45 | 201.00 |

| 2 | 154 | 24 | 60 | 30 | 0.51 | 274.00 |

| 1 | 224 | 24 | 80 | 45 | 0.65 | 419.00 |

| 1/0 | 273 | 24 | 80 | 45 | 0.69 | 492.00 |

| 2/0 | 323 | 24 | 80 | 45 | 0.74 | 575.00 |

| 3/0 | 426 | 24 | 80 | 45 | 0.83 | 770.00 |

| 4/0 | 551 | 24 | 80 | 45 | 0.89 | 884.00 |

| 263 | 646 | 24 | 95 | 65 | 1.01 | 1114.00 |

| 313 | 779 | 24 | 95 | 65 | 1.08 | 1309.00 |

| 374 | 931 | 24 | 95 | 65 | 1.14 | 1528.00 |

| 444 | 1110 | 24 | 95 | 65 | 1.22 | 1785.00 |

| 535 | 1332 | 24 | 110 | 65 | 1.33 | 2140.00 |

| 646 | 1591 | 24 | 110 | 65 | 1.42 | 2546.00 |

| 778 | 1952 | 24 | 110 | 65 | 1.53 | 3017.00 |

| 929 | 2318 | 24 | 110 | 65 | 1.64 | 3529.00 |

| 1111 | 2745 | 24 | 125 | 95 | 1.85 | 4291.00 |

- Next: Type Shd-Gc, Mining Cable, Cu/Epr/TPU, 3/C, 15kv (ICEA S-75-381/NEMA WC-58)

- Previous: Type Shd-Gc, Mining Cable, Cu/Epr/TPU, 3/C, 25kv (ICEA S-75-381/NEMA WC-58)

Contact us

Similar Or Related

-

10X1.5mm2 Flame Retardant Copper Tape Screen Steel Tape Armored PVC Sheathed Control Cable 0.6/1kV

-

0.3/0.5kV 4X4mm2 Copper Wire Braiding PVC Insulation Low Voltage Control Power Cable

-

24X2.5mm2 XLPE Insulated Steel Tape Armoured Control/Instrumentation Cable IEC 60502-1

-

Low Voltage Single Core Power Cable 1X300 mm2 N2XCH CU/XLPE/CWS/LSF 0.6/1kV

-

Dlo, Diesel Locomotive Cable, 2 Kv, 1/C, Cu/Epr/CPE (ICEA S-95-658/NEMA WC70/UL 44/CSA C22.2 No. 38)