Al/PVC/Sta/PVC, 0.6/1 Kv, Steel Tape Armor Power Cable (IEC 60502-1)

Product Description

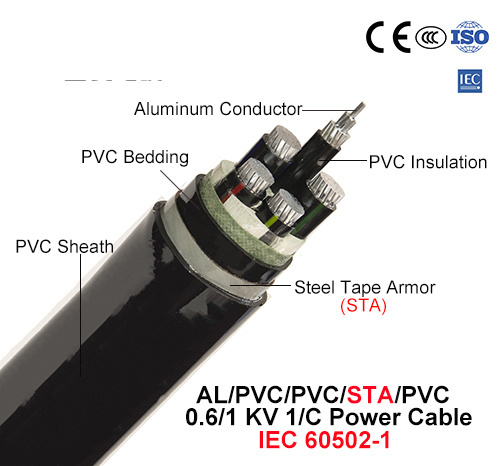

CONSTRUCTION

Conductor: Stranded circular (rm) or sector shaped (sm) aluminum conductor, as per Class 2 of IEC 60228.

Insulation: An extruded layer of Polyvinyl chloride (PVC) insulation, rated 70 º C at normal operation to IEC 60502-1.

Bedding: An extruded layer of Polyvinyl chloride (PVC).

Armouring: Double layer of galvanized steel tapes.

Outer sheath: An extruded layer of Polyvinyl chloride (PVC) sheathing compound type ST1 to IEC 60502-1.

APPLICATION

For outdoor installations in power stations, industrial plants and switchgears if mechanical protection is required or in applications where mechanical damages are expected to occur.

TECHNICAL DATA

– Nominal voltage Uo/U = 0.6/1 kV

– Power frequency test voltage 3.5 kV for 5 minutes

– Max. Admissible temperature of conductor at normal operation 70 º C

– Max. Admissible temperature of conductor at short circuit 160 º C for 5 seconds

| Cross-section | Max. Conductor Resistance | Current Rating | Overall Diameter | Cable Weight | |||

| DC at 20 | AC at 70 | Laid in Ground | Laid in Ducts | Laid in free air | |||

| mm2 | Ω/km | A | mm | kg/km | |||

| Two Cores | |||||||

| 10 | 3.0800 | 3.3000 | 46 | 39 | 46 | 16.7 | 455 |

| 16 | 1.9100 | 2.2900 | 60 | 46 | 62 | 20.7 | 540 |

| 25 | 1.2000 | 1.4400 | 77 | 60 | 81 | 24.1 | 730 |

| 35 | 0.8680 | 1.0430 | 103 | 83 | 115 | 26.3 | 880 |

| Three Cores | |||||||

| 10 | 3.0800 | 3.3000 | 42 | 34 | 37 | 19.7 | 535 |

| 16 | 1.9100 | 2.2900 | 53 | 42 | 50 | 21.8 | 625 |

| 25 | 1.2000 | 1.4400 | 70 | 56 | 66 | 25.5 | 855 |

| 35 | 0.8680 | 1.0430 | 95 | 75 | 88 | 25.8 | 1250 |

| Four Cores | |||||||

| 10 | 3.0800 | 3.3000 | 42 | 34 | 37 | 21.3 | 630 |

| 16 | 1.9100 | 2.2900 | 53 | 42 | 50 | 23.7 | 775 |

| 25 | 1.2000 | 1.4400 | 70 | 56 | 66 | 27.8 | 1035 |

| 35 | 0.8680 | 1.0430 | 95 | 75 | 88 | 27.9 | 1115 |

| 50 | 0.6410 | 0.7710 | 115 | 85 | 105 | 32.7 | 1475 |

| 70 | 0.4430 | 0.5330 | 135 | 110 | 132 | 37.5 | 2225 |

| 95 | 0.3200 | 0.3850 | 165 | 130 | 160 | 42.4 | 2830 |

| 120 | 0.2530 | 0.3050 | 185 | 150 | 187 | 46.2 | 3360 |

| 150 | 0.2060 | 0.2490 | 210 | 170 | 215 | 50.9 | 3975 |

| 185 | 0.1640 | 0.1990 | 235 | 195 | 248 | 56.1 | 4815 |

| 240 | 0.1250 | 0.1510 | 275 | 225 | 292 | 62.6 | 5925 |

| 300 | 0.1000 | 0.1230 | 310 | 260 | 347 | 68.7 | 7125 |

| 4+1 Cores | |||||||

| 35/16 | 0.8680 / 1.9100 | 1.0430 / 2.2900 | 95 | 75 | 88 | 26.8 | 1030 |

| 50/25 | 0.6410 / 1.2000 | 0.7710 / 1.4400 | 115 | 85 | 105 | 30.9 | 1330 |

| 70/35 | 0.4430 / 0.8680 | 0.5330 / 1.0430 | 135 | 110 | 132 | 34.6 | 1675 |

| 95/50 | 0.3200 / 0.6410 | 0.3850 / 0.7710 | 165 | 130 | 160 | 40.7 | 2585 |

| 120/70 | 0.2530 / 0.4430 | 0.3050 / 0.5330 | 185 | 150 | 187 | 44.5 | 3100 |

| 150/70 | 0.2060 / 0.4430 | 0.2490 / 0.5330 | 210 | 170 | 215 | 48.5 | 3590 |

| 185/95 | 0.1640 / 0.3200 | 0.1990 / 0.3850 | 235 | 195 | 248 | 53.2 | 4300 |

| 240/120 | 0.1250 / 0.2530 | 0.1510 / 0.3050 | 275 | 225 | 292 | 59.6 | 5325 |

| 300/150 | 0.1000 / 0.2060 | 0.1230 / 0.2490 | 310 | 260 | 347 | 65.4 | 6365 |

- Next: 1-Yy, Power Cable, 0.6/1 Kv, 1/C, Cu/PVC/PVC (TP-KK-133/01)

- Previous: Cu/XLPE/Lszh/Awa/Lszh, 1/C Power Cable, 0.6/1 Kv (BS 6724)

Contact us

Similar Or Related

-

10X1.5mm2 Flame Retardant Copper Tape Screen Steel Tape Armored PVC Sheathed Control Cable 0.6/1kV

-

0.3/0.5kV 4X4mm2 Copper Wire Braiding PVC Insulation Low Voltage Control Power Cable

-

24X2.5mm2 XLPE Insulated Steel Tape Armoured Control/Instrumentation Cable IEC 60502-1

-

Low Voltage Single Core Power Cable 1X300 mm2 N2XCH CU/XLPE/CWS/LSF 0.6/1kV

-

Al/PVC/Sta/PVC, 0.6/1 Kv, Steel Tape Armor Power Cable (IEC 60502-1)